Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 17, 2025 15:35

Back to list

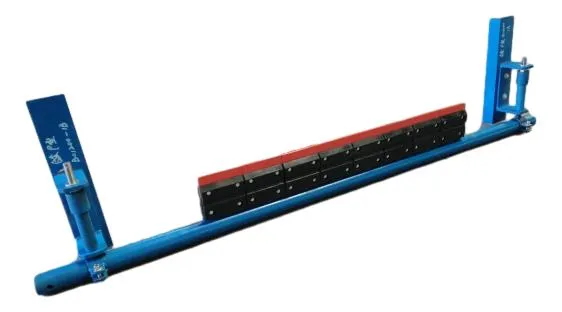

Belt Conveyor Idler

Exploring the Intricacies of Conveyor Idler Specifications

The spacing of idlers along the conveyor belt can significantly impact operational efficiency. Optimal spacing provides adequate support, preventing belt sagging and improving load distribution. However, excessively close spacing can lead to increased operational costs due to higher material and maintenance needs. Engineers must balance these factors to optimize performance and cost-efficiency. One often overlooked, yet vital specification is the idler's capacity to handle specific speed requirements. Conveyor speed is crucial as it dictates the material flow rate, directly affecting productivity. Idlers must be selected based on their ability to support the desired conveyor speed without generating excessive heat or noise, ensuring efficient and quiet operation. Noise levels are an additional consideration in the design and specification of conveyor idlers. Excessive noise can indicate design flaws or operational inefficiencies. Quality idlers are engineered to operate quietly, enhancing workplace comfort and meeting regulatory noise control standards. Conveyor idlers are more than mere components; they are pivotal to the efficient and effective operation of a conveyor system. Understanding the intricacies of idler specifications helps to ensure the design of a conveyor system that meets specific operational and environmental needs. By integrating knowledge of the materials, dimensions, and technical capabilities of various idler types, engineers can devise systems that optimize performance while minimizing downtime and maintenance. Experience and expertise in selecting the right conveyor idler can significantly enhance the operational success of a materials handling system. A robust understanding and application of idler specifications translate into systems that not only meet current demands but are equipped to adapt to future challenges, cementing reliability and efficiency across industrial landscapes.

The spacing of idlers along the conveyor belt can significantly impact operational efficiency. Optimal spacing provides adequate support, preventing belt sagging and improving load distribution. However, excessively close spacing can lead to increased operational costs due to higher material and maintenance needs. Engineers must balance these factors to optimize performance and cost-efficiency. One often overlooked, yet vital specification is the idler's capacity to handle specific speed requirements. Conveyor speed is crucial as it dictates the material flow rate, directly affecting productivity. Idlers must be selected based on their ability to support the desired conveyor speed without generating excessive heat or noise, ensuring efficient and quiet operation. Noise levels are an additional consideration in the design and specification of conveyor idlers. Excessive noise can indicate design flaws or operational inefficiencies. Quality idlers are engineered to operate quietly, enhancing workplace comfort and meeting regulatory noise control standards. Conveyor idlers are more than mere components; they are pivotal to the efficient and effective operation of a conveyor system. Understanding the intricacies of idler specifications helps to ensure the design of a conveyor system that meets specific operational and environmental needs. By integrating knowledge of the materials, dimensions, and technical capabilities of various idler types, engineers can devise systems that optimize performance while minimizing downtime and maintenance. Experience and expertise in selecting the right conveyor idler can significantly enhance the operational success of a materials handling system. A robust understanding and application of idler specifications translate into systems that not only meet current demands but are equipped to adapt to future challenges, cementing reliability and efficiency across industrial landscapes.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS