Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 17, 2025 14:56

Back to list

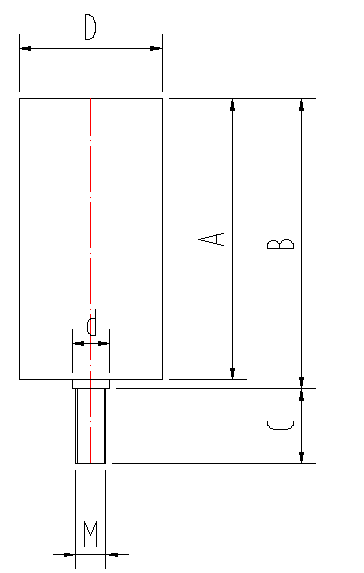

Belt Conveyor Idler

Conveyor idlers are an essential component in the complex framework of material handling systems, providing critical support and enhancing the efficiency of conveyor belts. Their significance cannot be overstated, given how they influence the reliability and productivity of conveyor operations, an area where experience, expertise, authority, and trustworthiness play a pivotal role.

Authority in the production of conveyor idlers is often validated by compliance with international standards such as ISO, CEMA, and DIN. Manufacturers and suppliers with certified processes gain trust from industry stakeholders, reinforcing their reliability and authority in the market. These standards guarantee that the idlers deliver consistent performance, upholding safety and operational efficiency. Industry leaders collaborate with standardization bodies to continuously refine the quality benchmarks and address the evolving challenges faced in different sectors, fortifying their status as authoritative voices in the industry. Trustworthiness is further cemented through transparent communication and after-sales support offered by leading conveyor idler providers. Building long-term partnerships with clients involves offering not just high-quality products, but also maintenance services and operational insights that prevent disruptions and prolong equipment life. Customer testimonials and case studies often highlight real-world success stories where reliable idlers have successfully enhanced operational efficiencies and reduced overall operational costs. These documented experiences reinforce trust, offering tangible proof of the idlers' capabilities and the supplier's commitment to quality. In conclusion, the deployment of conveyor idlers is not a mere technical decision; it is a strategic choice that leverages experience, expertise, authority, and trustworthiness. As industries continue to push for efficiency and productivity, idlers will remain pivotal in underpinning the performance of conveyor systems. Engaging with authoritative and experienced providers ensures that the implementation of such systems is executed with precision and dependability, fostering sustainable growth and operational excellence. As the industry evolves, continual investment in research, technological innovation, and customer collaboration will further enhance the performance parameters of conveyor idlers, ensuring they meet tomorrow's challenges today.

Authority in the production of conveyor idlers is often validated by compliance with international standards such as ISO, CEMA, and DIN. Manufacturers and suppliers with certified processes gain trust from industry stakeholders, reinforcing their reliability and authority in the market. These standards guarantee that the idlers deliver consistent performance, upholding safety and operational efficiency. Industry leaders collaborate with standardization bodies to continuously refine the quality benchmarks and address the evolving challenges faced in different sectors, fortifying their status as authoritative voices in the industry. Trustworthiness is further cemented through transparent communication and after-sales support offered by leading conveyor idler providers. Building long-term partnerships with clients involves offering not just high-quality products, but also maintenance services and operational insights that prevent disruptions and prolong equipment life. Customer testimonials and case studies often highlight real-world success stories where reliable idlers have successfully enhanced operational efficiencies and reduced overall operational costs. These documented experiences reinforce trust, offering tangible proof of the idlers' capabilities and the supplier's commitment to quality. In conclusion, the deployment of conveyor idlers is not a mere technical decision; it is a strategic choice that leverages experience, expertise, authority, and trustworthiness. As industries continue to push for efficiency and productivity, idlers will remain pivotal in underpinning the performance of conveyor systems. Engaging with authoritative and experienced providers ensures that the implementation of such systems is executed with precision and dependability, fostering sustainable growth and operational excellence. As the industry evolves, continual investment in research, technological innovation, and customer collaboration will further enhance the performance parameters of conveyor idlers, ensuring they meet tomorrow's challenges today.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS