Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 04, 2025 00:44

Back to list

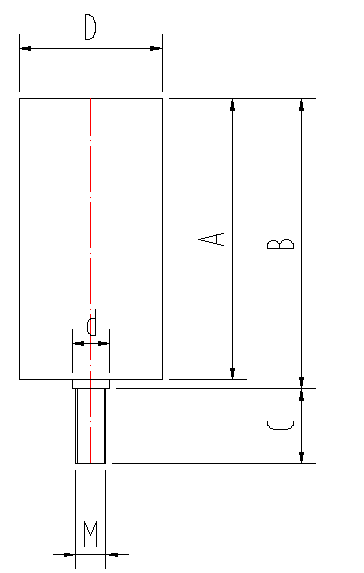

conveyor idler rollers

Conveyor idler rollers are integral components in the materials handling industry, contributing significantly to the efficiency and reliability of conveyor systems. With years of expertise in conveyor technology and a keen eye for the evolving demands of industrial operations, understanding the multifaceted role of idler rollers can dramatically enhance system performance and longevity.

From a professional standpoint, the precision in the manufacture of idler rollers extends beyond basic requirements. Ensuring that rollers are balanced and true allows for smoother operation and reduced noise levels, which is a critical consideration in environments where noise pollution might pose regulatory or workplace challenges. By leveraging modern machining technologies, manufacturers can deliver products that consistently meet stringent industrial standards, reinforcing their authoritative position in the market. Trustworthiness in conveyor idler rollers is built through rigorous testing and quality assurance processes. Ensuring that each roller can handle specified loads without compromising on speed or efficiency is crucial. As a result, leading manufacturers perform extensive testing under simulated operating conditions to validate product reliability. This commitment to quality not only promotes enhanced operational performance but also instills confidence in end-users making substantial investments in their conveyor systems. Through expert consultancy, choosing the right idler roller configuration can be optimized for specific production requirements. Illustrated through case studies of leading companies that have achieved significant reductions in downtime and operational costs, expertise in roller selection and conveyor system integration has proven to be a competitive differentiator. Finally, maintaining a knowledge-sharing culture within the industry ensures that technological advancements and empirical data are effectively communicated. This culture fosters an environment of collaboration and innovation, enabling continuous improvement in design, materials, and techniques. By staying at the forefront of industry developments, companies demonstrate a commitment to providing robust, efficient, and sustainable solutions. In conclusion, conveyor idler rollers, though often overlooked, are crucial to the seamless operation of conveyor systems. Through meticulous attention to design, material selection, and quality assurance, these components significantly influence the efficiency of material transportation. By leveraging expert insight and embracing industry innovations, businesses can maximize their conveyor system's performance, ensuring sustainable and profitable operations.

From a professional standpoint, the precision in the manufacture of idler rollers extends beyond basic requirements. Ensuring that rollers are balanced and true allows for smoother operation and reduced noise levels, which is a critical consideration in environments where noise pollution might pose regulatory or workplace challenges. By leveraging modern machining technologies, manufacturers can deliver products that consistently meet stringent industrial standards, reinforcing their authoritative position in the market. Trustworthiness in conveyor idler rollers is built through rigorous testing and quality assurance processes. Ensuring that each roller can handle specified loads without compromising on speed or efficiency is crucial. As a result, leading manufacturers perform extensive testing under simulated operating conditions to validate product reliability. This commitment to quality not only promotes enhanced operational performance but also instills confidence in end-users making substantial investments in their conveyor systems. Through expert consultancy, choosing the right idler roller configuration can be optimized for specific production requirements. Illustrated through case studies of leading companies that have achieved significant reductions in downtime and operational costs, expertise in roller selection and conveyor system integration has proven to be a competitive differentiator. Finally, maintaining a knowledge-sharing culture within the industry ensures that technological advancements and empirical data are effectively communicated. This culture fosters an environment of collaboration and innovation, enabling continuous improvement in design, materials, and techniques. By staying at the forefront of industry developments, companies demonstrate a commitment to providing robust, efficient, and sustainable solutions. In conclusion, conveyor idler rollers, though often overlooked, are crucial to the seamless operation of conveyor systems. Through meticulous attention to design, material selection, and quality assurance, these components significantly influence the efficiency of material transportation. By leveraging expert insight and embracing industry innovations, businesses can maximize their conveyor system's performance, ensuring sustainable and profitable operations.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS