Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor idler roller design

Conveyor Idler Roller Design An Essential Component for Efficient Material Handling

In the world of industrial material handling, the conveyor system is a critical element that facilitates the movement of bulk materials across various distances. One of the key components of a conveyor system is the idler roller, which plays a vital role in supporting the conveyor belt and ensuring smooth operation. This article delves into the design principles, functionality, and importance of conveyor idler rollers, emphasizing how effective design can enhance overall system efficiency.

Understanding Idler Rollers

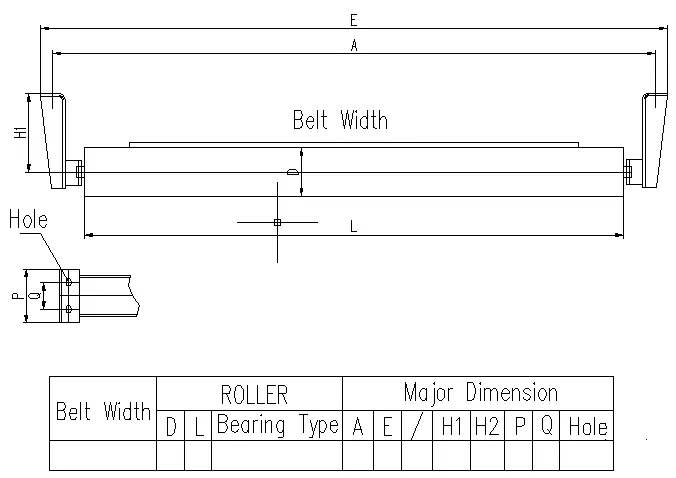

Idler rollers are cylindrical tubes used to support the weight of the conveyor belt and the materials being transported. They are typically mounted on frames and positioned at regular intervals along the conveyor line. The primary function of idler rollers is to provide a surface for the belt to run on, reducing friction and wear while minimizing the load on drive components.

Design Principles

When designing conveyor idler rollers, several critical factors must be considered to ensure optimal performance and longevity

1. Material Selection The choice of materials for idler rollers significantly impacts their durability and performance. Most idler rollers are made from steel or plastic, with steel providing better strength and resistance to heavy loads while plastic offers benefits in corrosion resistance and weight reduction. For applications involving harsh environments, such as chemical exposure, selecting the right material is crucial.

2. Diameter and Length The diameter of the idler roller affects the belt tension and the overall capacity of the conveyor system. Larger diameter rollers can better support heavier loads, while smaller rollers are suitable for lighter applications. The length of the roller should match the conveyor width to ensure proper alignment and prevent belt misalignment.

3. Bearing Type The type of bearings used in idler rollers greatly influences their operational efficiency. Sealed bearings or self-aligning bearings are often preferred as they require less maintenance and exhibit superior performance under varying operational conditions. Proper bearing selection also ensures that the rollers operate with minimal friction, which is critical for energy efficiency.

4. Roller Spacing The spacing of idler rollers is essential for preventing belt sagging and maintaining tension. The distance between rollers should be optimized based on the type of material being conveyed, the overall length of the conveyor, and the specific physical characteristics of the belt. Improper spacing can lead to increased wear on both the roller and the belt, resulting in costly downtime.

conveyor idler roller design

5. Coating and Finish The surface finish of the idler rollers can impact both their wear resistance and the friction between the roller and the conveyor belt. Coatings such as powder coating or galvanization can provide additional protection against environmental factors, thus extending the lifespan of the rollers.

Importance of Proper Design

Investing in well-designed conveyor idler rollers has multiple benefits

- Increased Efficiency Efficient design reduces energy consumption by minimizing friction between the roller and the belt, leading to lower operational costs.

- Enhanced Durability Properly designed rollers mitigate wear and tear, reducing the need for frequent replacements and maintenance.

- Improved Material Flow Well-placed and correctly spaced idler rollers facilitate optimal belt tracking, minimizing the risk of product spillage and ensuring a smooth flow of materials.

- Environmental Impact By optimizing the design, companies can decrease energy use and reduce their carbon footprint, making their operations more sustainable.

Conclusion

In conclusion, the design of conveyor idler rollers is a critical aspect of establishing an efficient material handling system. By focusing on key design parameters such as material selection, diameter, bearing type, roller spacing, and surface finish, engineers can create robust idler rollers that enhance the overall performance of conveyor systems. As industries continue to evolve, embracing innovative designs and technologies will be pivotal in meeting the growing demands for efficiency, reliability, and sustainability in material handling operations. Understanding and implementing these design principles will not only lead to increased productivity but also foster a culture of safety and environmental responsibility in industrial settings.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025