Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

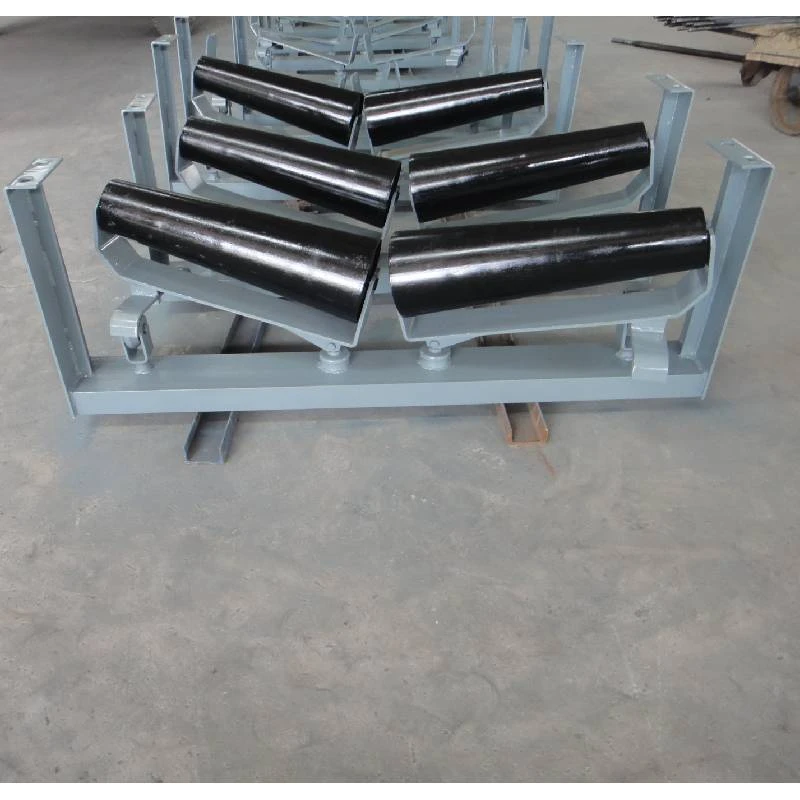

Zulu Top Manufacturers of Conveyor Idlers for Efficient Material Handling Solutions

The Role of Conveyor Idler Manufacturers in Modern Industries

Conveyor systems are integral to a vast array of industries, from mining and manufacturing to food processing and logistics. At the heart of these systems lies the conveyor idler, a crucial component that supports the conveyor belt and ensures efficient material handling. As industries continue to expand and evolve, the role of conveyor idler manufacturers has become increasingly significant.

What is a Conveyor Idler?

A conveyor idler is a roller that supports the conveyor belt, allowing it to move smoothly across its path. Idlers are designed to reduce friction and wear on the belt while providing stability and support. Typically made from robust materials such as steel or plastic, idlers must withstand harsh environmental conditions, including heavy loads, dust, and moisture. The efficiency of the entire conveyor system relies heavily on the quality and design of its idlers.

The Importance of Conveyor Idler Manufacturers

1. Design and Innovation Conveyor idler manufacturers play a vital role in designing idlers that meet the specific needs of various industries. With advancements in technology, manufacturers are developing innovative idler designs that enhance durability, reduce maintenance costs, and improve performance. For instance, some manufacturers are introducing self-aligning idlers that help keep the belt centered, reducing wear and preventing costly downtime.

2. Customization Different industries have unique requirements based on the materials they handle and their operational environments. Conveyor idler manufacturers offer customization options to cater to these specific needs. Whether it's the size, material, or configuration of the idlers, manufacturers work closely with clients to provide tailored solutions that optimize their conveyor systems.

3. Quality Assurance The quality of idlers directly impacts the efficiency and longevity of conveyor systems. Reputable manufacturers adhere to strict quality control standards, ensuring that their products meet industry regulations and benchmarks. This commitment to quality not only increases the lifespan of idlers but also minimizes the risk of breakdowns and maintenance issues in conveyor systems.

conveyor idler manufacturers

4. Sustainability Initiatives In today’s environmentally conscious world, many conveyor idler manufacturers are incorporating sustainable practices into their operations. This includes using recycled materials, reducing waste during production, and designing idlers that are energy efficient. By focusing on sustainability, manufacturers not only contribute to environmental conservation but also help their clients meet regulatory requirements and corporate social responsibility goals.

5. Market Trends The global market for conveyor idlers is continuously evolving, influenced by trends such as automation and the increasing demand for efficiency in material handling. Manufacturers who stay ahead of these trends by adopting the latest technologies and innovations are better positioned to succeed. For instance, the integration of IoT (Internet of Things) in conveyor systems allows for real-time monitoring and maintenance of idlers, thereby reducing unexpected failures and enhancing operational efficiency.

Challenges Faced by Conveyor Idler Manufacturers

Despite the promising landscape, conveyor idler manufacturers face several challenges. Supply chain disruptions, fluctuating raw material prices, and evolving industry standards can impact production and pricing. Additionally, as competition grows, manufacturers must continuously innovate and differentiate their products to maintain market share.

Moreover, the need for skilled labor in manufacturing processes is becoming a pressing issue. As technology advances, manufacturers must invest in training and development to ensure their workforce is equipped with the necessary skills to leverage new technologies effectively.

Conclusion

In conclusion, conveyor idler manufacturers are pivotal to the success of industries that rely on effective material handling solutions. Their commitment to innovation, quality, and sustainability not only enhances the performance of conveyor systems but also contributes to the overall efficiency of industrial operations. As industries continue to adapt to new challenges and technologies, the role of these manufacturers will remain crucial in supporting the ever-evolving landscape of conveyor systems. Ensuring that idlers are well-designed, durable, and suited to specific applications will be key to maintaining operational excellence across various sectors.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025