Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

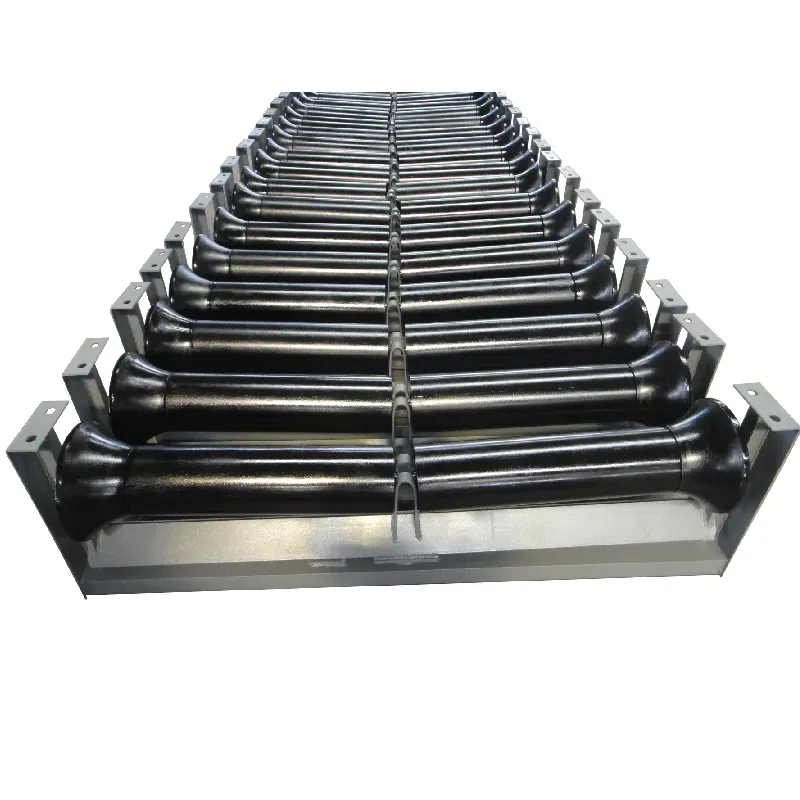

Zulu conveyor head roller

The Importance of Conveyor Head Rollers in Modern Industry

In the realm of modern manufacturing and material handling, conveyor systems play a pivotal role in ensuring efficiency and productivity. One of the critical components of these systems is the conveyor head roller. Often overlooked, this simple yet essential part is integral to the overall functioning of conveyor belts and directly impacts operational efficacy. This article delves into the importance of conveyor head rollers, their functions, designs, and applications across various industries.

Understanding Conveyor Head Rollers

Conveyor head rollers, sometimes referred to as drive rollers, are located at the discharge end of a conveyor system. They serve two primary purposes they help in the propulsion of the conveyor belt and provide tension, thus keeping the system taut and functional. The functionality of these rollers is crucial as they contribute to the seamless movement of materials, ensuring smooth transitions and minimizing delays in transport processes.

Functionality of Head Rollers

The primary function of a conveyor head roller is to drive the conveyor belt. As the roller rotates, it engages with the belt, allowing it to move forward. This mechanism is essential for transporting goods efficiently from one point to another within a facility. Additionally, head rollers help maintain the necessary tension in the conveyor belt. Proper tension is vital for the belt's stability, load-carrying capacity, and overall performance.

Moreover, head rollers often come with features that enhance their performance. Many modern designs include a crowned surface to aid in belt tracking, ensuring that the belt stays aligned and reducing wear and tear. Some head rollers are equipped with rubber coatings or special materials to increase friction and improve grip, especially when transporting heavy or slippery objects.

Design and Materials

The design of conveyor head rollers can vary significantly based on their application. Factors such as diameter, length, and material composition are critical in optimizing performance. Common materials used for constructing head rollers include steel, stainless steel, and aluminum. Each material offers distinctive advantages—steel is known for its strength and durability, while stainless steel is highly resistant to corrosion and is ideal for the food and pharmaceutical industries.

conveyor head roller

The size of the roller is also a crucial aspect. Larger rollers may be necessary for heavy-duty applications, whereas smaller rollers can be suitable for lighter materials. Additionally, custom designs can be employed to meet specific operational requirements, ensuring that the roller is perfectly suited to the application.

Applications Across Industries

Conveyor head rollers find applications across a wide range of industries. In manufacturing, they are used to transport raw materials and finished products along assembly lines, enhancing productivity and operational efficiency. The logistics and distribution sectors rely heavily on conveyor systems with head rollers to facilitate the swift movement of goods, improving turnaround times and reducing labor costs.

In the food processing industry, head rollers are essential in ensuring safe and hygienic transport. They are often designed with specific features to minimize contamination risks and can be easily cleaned. Similarly, the pharmaceutical industry requires head rollers that meet stringent regulatory standards, ensuring that products are handled in a safe and compliant manner.

Moreover, industries such as mining and agriculture utilize heavy-duty conveyors with robust head rollers to handle bulk materials such as ores, grains, and fertilizers. The ability of these rollers to withstand harsh conditions and heavy loads makes them indispensable in such environments.

Conclusion

In conclusion, conveyor head rollers, though they may seem simple, are fundamental to the smooth operation of conveyor systems across various industries. Their ability to drive the conveyor belt, maintain tension, and provide durability is essential for achieving high levels of productivity and efficiency. As industries continue to evolve and seek out more efficient material handling solutions, the importance of high-quality conveyor head rollers will only increase. Investing in robust and well-designed head rollers can lead to significant improvements in operations, reduced maintenance costs, and a more streamlined production process. Understanding and optimizing the performance of these components is crucial for any business that relies on effective conveyance systems.

With the rapid advancements in technology and materials, we can anticipate even more innovative designs in conveyor head rollers, which will undoubtedly enhance their functionality and increase their importance in various industrial applications.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025