Feb . 20, 2025 13:47

Back to list

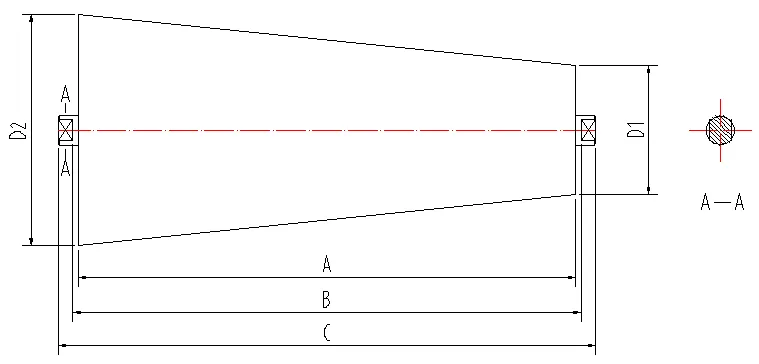

Bend Pulley (Non-driving Pulley)

Understanding the pivotal role of the conveyor head pulley in many industrial operations can't be overstated. The head pulley plays a critical role in the conveyor system's performance, ensuring efficiency and reliability across diverse applications in manufacturing, mining, and other sectors. This component is the driving force that moves the conveyor belt, facilitating the smooth transition of materials from one point to another. By delving into its functions, design considerations, and maintenance practices, we can appreciate its importance in optimizing productivity and enhancing system longevity.

Maintenance of the conveyor head pulley is another critical aspect that underscores its significance in industrial operations. Routine inspections and timely interventions are vital in identifying and rectifying potential issues before they lead to costly system failures. Regularly checking for signs of wear, such as unusual noises, belt slippage, or visible damage, can prevent more significant problems down the line. Furthermore, ensuring that the pulley is free from material build-up, especially in operations involving sticky or abrasive substances, prolongs its lifespan and maintains its operational efficiency. Additionally, the adaptability of the conveyor head pulley to different environmental conditions makes it a versatile component in various industrial applications. Whether exposed to extreme temperatures or corrosive environments, selecting the appropriate material and coatings for the head pulley can significantly enhance its resistance to harsh conditions. Investing in pulleys that are tailored to specific environmental challenges can greatly improve the overall reliability and performance of the entire conveyor system in demanding settings. In conclusion, the conveyor head pulley is an indispensable component in any efficient conveyor system. Its influence extends beyond just facilitating material movement; it is integral to maintaining optimal productivity and cost-effectiveness in industrial operations. By emphasizing robust design, strategic maintenance, and adaptability to environmental conditions, businesses can ensure that their conveyor head pulleys not only meet but exceed operational expectations. As industries continue to evolve, embracing innovations in head pulley technology and engineering will be key to sustaining competitive advantages and operational excellence.

Maintenance of the conveyor head pulley is another critical aspect that underscores its significance in industrial operations. Routine inspections and timely interventions are vital in identifying and rectifying potential issues before they lead to costly system failures. Regularly checking for signs of wear, such as unusual noises, belt slippage, or visible damage, can prevent more significant problems down the line. Furthermore, ensuring that the pulley is free from material build-up, especially in operations involving sticky or abrasive substances, prolongs its lifespan and maintains its operational efficiency. Additionally, the adaptability of the conveyor head pulley to different environmental conditions makes it a versatile component in various industrial applications. Whether exposed to extreme temperatures or corrosive environments, selecting the appropriate material and coatings for the head pulley can significantly enhance its resistance to harsh conditions. Investing in pulleys that are tailored to specific environmental challenges can greatly improve the overall reliability and performance of the entire conveyor system in demanding settings. In conclusion, the conveyor head pulley is an indispensable component in any efficient conveyor system. Its influence extends beyond just facilitating material movement; it is integral to maintaining optimal productivity and cost-effectiveness in industrial operations. By emphasizing robust design, strategic maintenance, and adaptability to environmental conditions, businesses can ensure that their conveyor head pulleys not only meet but exceed operational expectations. As industries continue to evolve, embracing innovations in head pulley technology and engineering will be key to sustaining competitive advantages and operational excellence.

Next:

Latest news

-

Impact Roller for Belt Conveyor – Durable Solutions for IndustryNewsNov.24,2025

-

Rubber Conveyor Rollers – Quiet, Durable, Sealed BearingsNewsNov.24,2025

-

Industrial Conveyor Belt Rollers: Durable Solutions for Harsh EnvironmentsNewsNov.24,2025

-

Idler Rollers for Belt Conveyors | Durable, Low-Noise OEMNewsNov.24,2025

-

Durable Rubber Conveyor Belt Rollers for Industrial UseNewsNov.24,2025

-

Ceramic Lagging Conveyor Pulley – Anti-Slip, Wear-ResistantNewsNov.17,2025

OUR PRODUCTS