Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 17, 2025 01:28

Back to list

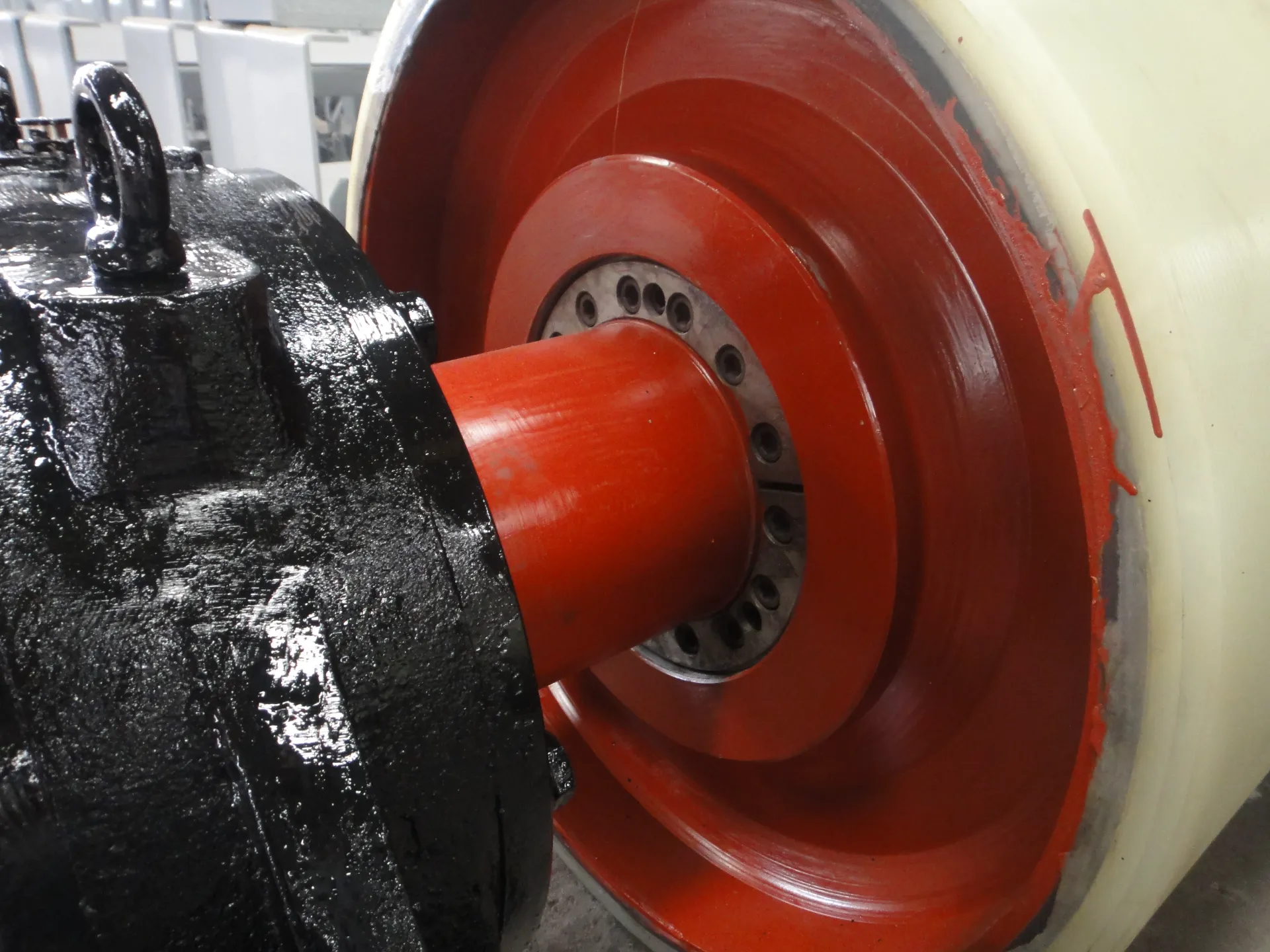

conveyor head pulley

In the realm of industrial operations, the conveyor head pulley stands as a quintessential component vital for the seamless movement of materials across various sectors, ranging from mining to agriculture. With years of hands-on experience, industry professionals understand the pivotal role this machinery component plays in ensuring operational efficiency, thereby making it indispensable in conveyor systems. As an expert in industrial machinery, I have witnessed firsthand how modern advancements have fine-tuned the efficacy of conveyor head pulleys, enhancing their performance and reliability.

Equally paramount is the precision in the engineering of the pulley’s design—balancing factors such as weight, diameter, and face width that collectively dictate the load-bearing capacity and operational stability. I've advised countless industrial entities on customizing these parameters to align with specific material-handling requirements. Engineering teams often collaborate with vendors to tailor head pulleys that confer unmatched performance, reflecting both the reliability and safety standards that industries demand. The trustworthiness of a conveyor head pulley manufacturer is another cornerstone to consider. In an industry rife with competition, manufacturers that consistently deliver quality and innovation gain a reputation for credibility and authoritativeness. My interactions and partnerships with various manufacturers have affirmed the value of certifications and compliance with international quality standards, such as ISO 9001. These certifications are not merely symbolic but are testament to a manufacturer’s commitment to excellence and reliability. Furthermore, my experience in conducting rigorous testing and analysis has highlighted the importance of real-world performance metrics. Engaging in empirical testing environments to simulate actual operations assists in verifying the head pulley's advertised competencies and in identifying potential areas for improvement. This approach not only buttresses trust in the product but also provides actionable insights that drive continual advancement in design and materials. In essence, the conveyor head pulley is the linchpin in the conveyor system’s operation, with its efficiency directly impacting overall productivity. By leveraging expert insights and placing a premium on quality and precision, industries can harness the full spectrum of advantages offered by advanced pulley systems. As the industrial landscape continues to evolve, so must the strategies in selecting and optimizing conveyor head pulleys, ensuring they remain an integral asset in the pursuit of operational excellence.

Equally paramount is the precision in the engineering of the pulley’s design—balancing factors such as weight, diameter, and face width that collectively dictate the load-bearing capacity and operational stability. I've advised countless industrial entities on customizing these parameters to align with specific material-handling requirements. Engineering teams often collaborate with vendors to tailor head pulleys that confer unmatched performance, reflecting both the reliability and safety standards that industries demand. The trustworthiness of a conveyor head pulley manufacturer is another cornerstone to consider. In an industry rife with competition, manufacturers that consistently deliver quality and innovation gain a reputation for credibility and authoritativeness. My interactions and partnerships with various manufacturers have affirmed the value of certifications and compliance with international quality standards, such as ISO 9001. These certifications are not merely symbolic but are testament to a manufacturer’s commitment to excellence and reliability. Furthermore, my experience in conducting rigorous testing and analysis has highlighted the importance of real-world performance metrics. Engaging in empirical testing environments to simulate actual operations assists in verifying the head pulley's advertised competencies and in identifying potential areas for improvement. This approach not only buttresses trust in the product but also provides actionable insights that drive continual advancement in design and materials. In essence, the conveyor head pulley is the linchpin in the conveyor system’s operation, with its efficiency directly impacting overall productivity. By leveraging expert insights and placing a premium on quality and precision, industries can harness the full spectrum of advantages offered by advanced pulley systems. As the industrial landscape continues to evolve, so must the strategies in selecting and optimizing conveyor head pulleys, ensuring they remain an integral asset in the pursuit of operational excellence.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS