Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 26, 2025 03:52

Back to list

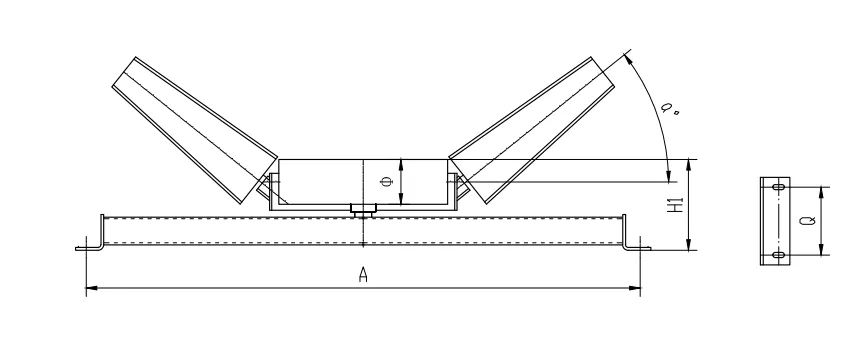

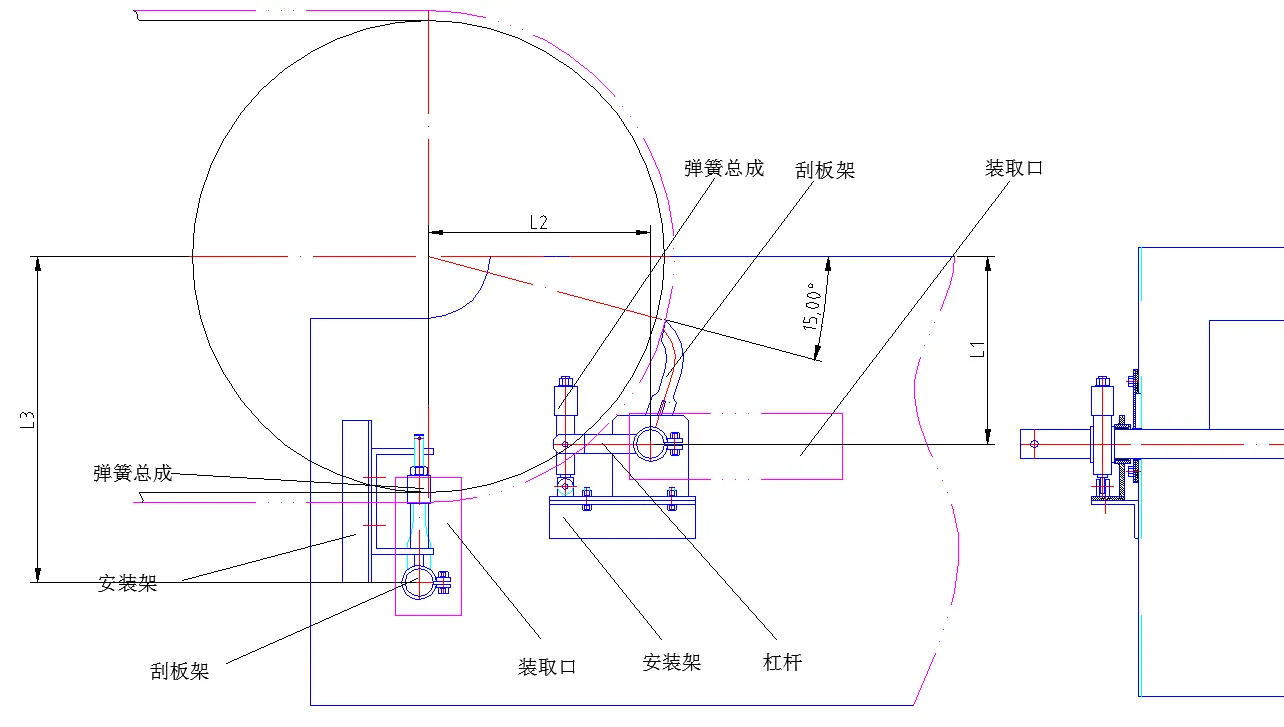

conveyor hanger

Conveyor hangers serve as an essential component in a variety of industries, underpinning the seamless transport of goods through conveyor systems. They facilitate efficiency and reliability, especially in environments that demand precision such as manufacturing, distribution, and warehousing. This article delves into the multifaceted role of conveyor hangers, shedding light on their design, application, and the nuances that make them indispensable in industrial operations.

The trustworthiness of conveyor hanger systems is non-negotiable in critical operations. The failure of a single component can lead to significant downtime and financial losses. Industries that require dependable conveyor systems often perform thorough audits of their mechanical components, with conveyor hangers receiving particular attention. This trust is built not just on the quality of the materials but also on the precision of installation and regular maintenance schedules. Training for workforce handling such systems includes understanding the role of these hangers and recognizing the early signs of wear and tear. Incorporating conveyor hangers into a facility’s workflow necessitates a holistic approach to system design. An effective layout acknowledges spatial constraints and operational goals while anticipating future expansions or modifications. Advanced sensors and automation technologies are now being integrated with conveyor systems, offering real-time data and predictive analytics that inform maintenance decisions—ensuring that conveyor hangers continue to perform optimally without human oversight. To further enhance experience, industries are adopting sustainable practices with their conveyor hanger usage. The life cycle assessments of these components consider their entire span—from material selection and manufacturing processes to eventual recycling. Such practices not only reduce the environmental footprint but also meet corporate responsibility standards that are increasingly prioritized by stakeholders and regulators alike. In conclusion, conveyor hangers are a vital cog in the wheel of industrial operation systems, combining expert engineering with practical innovation. Their role transcends their physical support capacity, as they embody the principles of precision, reliability, and sustainability. The choice of hangers should align with an organization’s operational ethos and future growth trajectory. As technology advances, the evolution of conveyor hangers is inevitable, promising greater integration and efficiency in industrial systems worldwide.

The trustworthiness of conveyor hanger systems is non-negotiable in critical operations. The failure of a single component can lead to significant downtime and financial losses. Industries that require dependable conveyor systems often perform thorough audits of their mechanical components, with conveyor hangers receiving particular attention. This trust is built not just on the quality of the materials but also on the precision of installation and regular maintenance schedules. Training for workforce handling such systems includes understanding the role of these hangers and recognizing the early signs of wear and tear. Incorporating conveyor hangers into a facility’s workflow necessitates a holistic approach to system design. An effective layout acknowledges spatial constraints and operational goals while anticipating future expansions or modifications. Advanced sensors and automation technologies are now being integrated with conveyor systems, offering real-time data and predictive analytics that inform maintenance decisions—ensuring that conveyor hangers continue to perform optimally without human oversight. To further enhance experience, industries are adopting sustainable practices with their conveyor hanger usage. The life cycle assessments of these components consider their entire span—from material selection and manufacturing processes to eventual recycling. Such practices not only reduce the environmental footprint but also meet corporate responsibility standards that are increasingly prioritized by stakeholders and regulators alike. In conclusion, conveyor hangers are a vital cog in the wheel of industrial operation systems, combining expert engineering with practical innovation. Their role transcends their physical support capacity, as they embody the principles of precision, reliability, and sustainability. The choice of hangers should align with an organization’s operational ethos and future growth trajectory. As technology advances, the evolution of conveyor hangers is inevitable, promising greater integration and efficiency in industrial systems worldwide.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS