Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor guide roller

Understanding Conveyor Guide Rollers Essential Components in Material Handling

In the world of industrial manufacturing and logistics, the efficient movement of materials is paramount. One critical component that plays a significant role in enhancing the functionality of conveyor systems is the conveyor guide roller. These components, often overlooked, are vital for ensuring that materials are transported smoothly and safely along conveyor belts. This article explores the importance, types, and applications of conveyor guide rollers in various industries.

What Are Conveyor Guide Rollers?

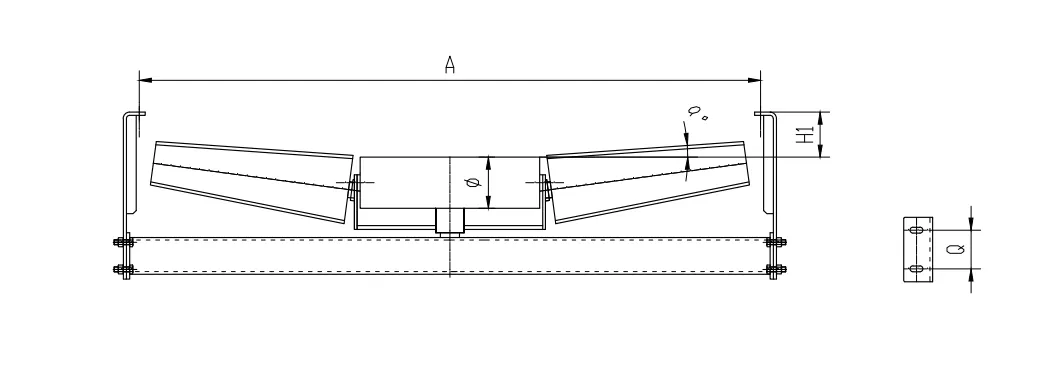

Conveyor guide rollers are cylindrical rollers that are positioned along the sides or within the structure of conveyor systems. Their primary function is to guide the conveyor belt, preventing it from wandering off track and ensuring stable material transport. Guide rollers are typically mounted on a frame or a bracket and can be adjusted to maintain proper belt alignment.

These rollers are available in various sizes, materials, and designs to accommodate different conveyor applications. The choice of material often depends on the specific industry usage, with common options including plastic, rubber, and metal. Each material offers distinct properties, such as durability, resistance to wear, and weight considerations.

Why Are Conveyor Guide Rollers Important?

1. Belt Alignment Conveyor systems operate under considerable tension and load. Guide rollers help maintain the correct belt alignment, which is essential to prevent belt misalignment that can lead to costly disruptions in workflow and equipment damage.

2. Reduced Wear and Tear By keeping the belt aligned and stable, guide rollers contribute to reducing wear on both the conveyor belt and the roller itself. This longevity is crucial for minimizing maintenance costs and extending the life of the entire conveyor system.

3. Safety Misalignment can lead to materials falling off the conveyor, posing safety hazards in the workplace. Effective guide rollers ensure that materials are held securely within the confines of the conveyor system, enhancing overall safety for operators and other personnel.

4. Efficiency A well-aligned conveyor system operates more efficiently, allowing for quicker transport of materials. This efficiency is vital in industries such as manufacturing, warehousing, and logistics, where time is often of the essence.

Types of Conveyor Guide Rollers

While the primary function of guide rollers is to maintain belt alignment, they come in various designs to suit diverse operational needs

conveyor guide roller

1. Flat Guide Rollers These rollers provide a stable surface for the conveyor belt to rest against, ensuring it remains on track without slipping or drifting.

3. Tapered Rollers Tapered rollers are beneficial for conveyor systems that experience lateral movement. They help guide the belt back to its center position without excessive friction.

4. Adjustable Guide Rollers These rollers offer the flexibility of height and angle adjustments, making them ideal for conveyor systems with varying belt widths and operational requirements.

Applications of Conveyor Guide Rollers

Conveyor guide rollers find applications across various industries, including

- Manufacturing In assembly lines, where materials need to move seamlessly from one stage to another, guide rollers prevent misalignment and ensure smooth delivery. - Logistics Warehouses rely heavily on conveyor systems for sorting and transporting goods. Effective guide rollers facilitate quick and accurate movement of items.

- Mining and Quarrying In environments where loads are heavy and conditions abrasive, robust guide rollers are essential for maintaining belt integrity and operational safety.

- Food Processing Conveyor systems in food processing require hygiene and safety. Guide rollers made of materials that can withstand cleaning cycles are vital in these settings.

Conclusion

In summary, conveyor guide rollers are crucial components that enhance the performance, safety, and efficiency of conveyor systems across various industries. By providing alignment and support, these rollers contribute significantly to the smooth operation of material handling processes. As industries continue to evolve, the demand for reliable and innovative conveyor guide roller solutions will only grow, highlighting their importance in manufacturing and logistics. Choosing the right type of guide roller tailored to specific needs ensures optimal performance and longevity of the conveyor system, ultimately driving productivity and safety in the workplace.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025