Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 29, 2025 04:07

Back to list

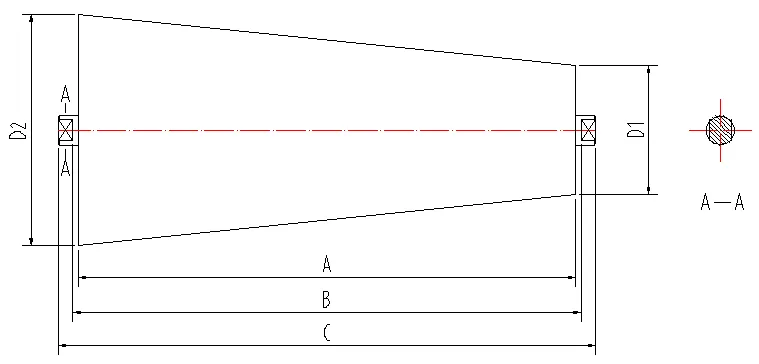

conveyor pulley components

The global manufacturing landscape is evolving at an unprecedented pace, with conveyor components manufacturers playing a pivotal role in streamlining industrial processes. These manufacturers are at the forefront of technological innovation, providing essential components that enhance efficiency, reduce downtime, and ensure safety across various sectors, including automotive, food processing, and logistics.

An experience-driven approach is vital for manufacturers to understand and anticipate client needs. By engaging closely with customers, manufacturers gain insights into specific operational challenges and requirements, allowing them to tailor their products accordingly. This client-centric approach not only enhances customer satisfaction but also drives innovation, as manufacturers develop customized solutions that address unique industrial needs. In product development, manufacturers leverage cutting-edge technologies such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) to design and produce components with precision and accuracy. Advanced manufacturing techniques, such as additive manufacturing and CNC machining, also play a role in the production of high-quality conveyor components. These technologies enable manufacturers to create intricate designs and maintain tight tolerances, ensuring components function optimally within conveyor systems. Moreover, the integration of IoT (Internet of Things) technologies into conveyor components is transforming the industry. IoT-enabled components can provide real-time data on operational performance, allowing for predictive maintenance and reducing the likelihood of unexpected failures. This technological advancement represents the fusion of manufacturing expertise and digital innovation, showcasing how manufacturers are adapting to the demands of Industry 4.0. Sustainability is another crucial factor driving the evolution of conveyor components manufacturing. Manufacturers are increasingly adopting eco-friendly practices, such as using recyclable materials and optimizing production processes to reduce carbon footprints. By committing to sustainable practices, manufacturers not only contribute to environmental preservation but also appeal to eco-conscious clients who prioritize sustainability in their operations. In conclusion, conveyor components manufacturers are instrumental in driving industrial efficiency and innovation. Through their commitment to quality, expertise in design and engineering, adherence to international standards, and a focus on sustainability, these manufacturers continue to set industry benchmarks. Their role as trusted partners in industrial operations underscores their importance in the global manufacturing ecosystem, advancing both technical prowess and environmental responsibility.

An experience-driven approach is vital for manufacturers to understand and anticipate client needs. By engaging closely with customers, manufacturers gain insights into specific operational challenges and requirements, allowing them to tailor their products accordingly. This client-centric approach not only enhances customer satisfaction but also drives innovation, as manufacturers develop customized solutions that address unique industrial needs. In product development, manufacturers leverage cutting-edge technologies such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) to design and produce components with precision and accuracy. Advanced manufacturing techniques, such as additive manufacturing and CNC machining, also play a role in the production of high-quality conveyor components. These technologies enable manufacturers to create intricate designs and maintain tight tolerances, ensuring components function optimally within conveyor systems. Moreover, the integration of IoT (Internet of Things) technologies into conveyor components is transforming the industry. IoT-enabled components can provide real-time data on operational performance, allowing for predictive maintenance and reducing the likelihood of unexpected failures. This technological advancement represents the fusion of manufacturing expertise and digital innovation, showcasing how manufacturers are adapting to the demands of Industry 4.0. Sustainability is another crucial factor driving the evolution of conveyor components manufacturing. Manufacturers are increasingly adopting eco-friendly practices, such as using recyclable materials and optimizing production processes to reduce carbon footprints. By committing to sustainable practices, manufacturers not only contribute to environmental preservation but also appeal to eco-conscious clients who prioritize sustainability in their operations. In conclusion, conveyor components manufacturers are instrumental in driving industrial efficiency and innovation. Through their commitment to quality, expertise in design and engineering, adherence to international standards, and a focus on sustainability, these manufacturers continue to set industry benchmarks. Their role as trusted partners in industrial operations underscores their importance in the global manufacturing ecosystem, advancing both technical prowess and environmental responsibility.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS