Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Top Manufacturers of Conveyor Components for Efficient Material Handling Solutions

Exploring Conveyor Components Manufacturers and Their Impact on Industry

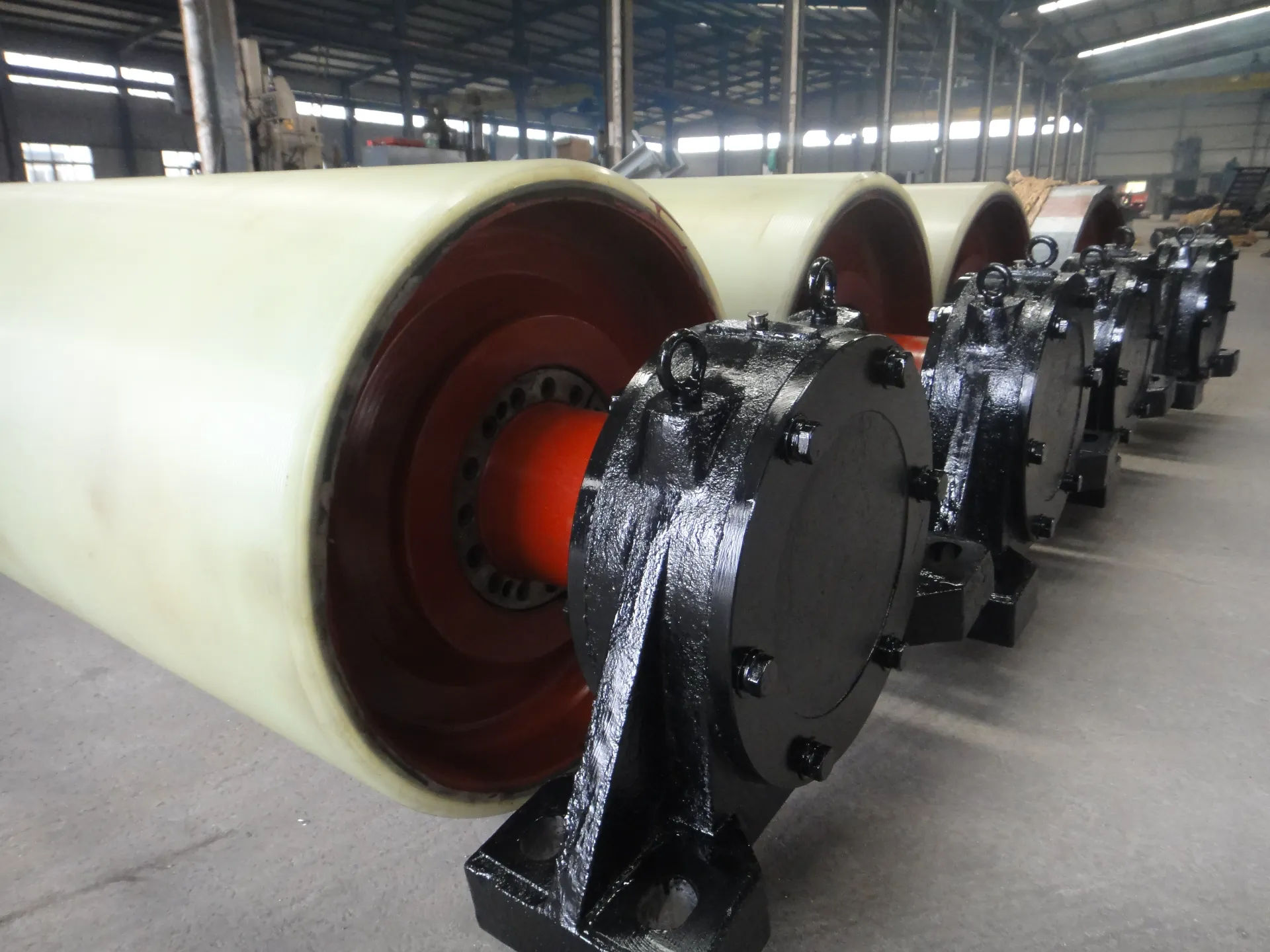

Conveyor systems play a pivotal role in modern manufacturing and logistics, facilitating the efficient movement of goods and materials. At the heart of these systems are conveyor components, which include belts, rollers, pulleys, and other essential parts that ensure optimal performance. Conveyor components manufacturers are critical to the success of various industries, from food and beverage to automotive and pharmaceuticals. This article will delve into the significant contributions of conveyor components manufacturers, the latest technological advancements, and the future of the industry.

First and foremost, conveyor components manufacturers provide the necessary parts that allow conveyor systems to function smoothly. They offer a wide array of products, each designed for specific applications and industries. For instance, food-grade conveyor belts are manufactured to meet stringent hygiene standards, making them suitable for the food and beverage sector. Similarly, heavy-duty rollers are designed for the transportation of heavy materials in manufacturing plants. The diversity of components available allows businesses to tailor their conveyor systems to meet their operational requirements.

Another critical aspect of conveyor components manufacturers is their commitment to innovation. As industries evolve and demand for increased efficiency grows, manufacturers are continually developing advanced components. For example, the introduction of smart sensors and automation technology has revolutionized conveyor systems. These innovations enable real-time monitoring and control of conveyor operations, ensuring optimal performance and reducing downtime. Manufacturers that invest in research and development are better positioned to offer state-of-the-art solutions that can enhance productivity and reduce operational costs for their clients.

conveyor components manufacturers

The growing focus on sustainability also plays an essential role in the conveyor components manufacturing industry. With increasing pressure on industries to reduce their carbon footprint, manufacturers are exploring eco-friendly materials and designs. For instance, some companies are developing conveyor belts made from recycled materials or designing components that are easier to disassemble and recycle at the end of their life cycle. These sustainable practices not only benefit the environment but also enhance a manufacturer's reputation and appeal to environmentally conscious consumers.

Additionally, conveyor components manufacturers are responding to the challenges posed by globalization. As supply chains become more complex and interconnected, the demand for reliable and durable components has surged. Manufacturers are expanding their global reach, establishing partnerships with suppliers and distributors around the world to ensure that they can meet the demands of various markets. This trend has led to the emergence of more competitive pricing and improved supply chain efficiency, ultimately benefiting end-users.

Furthermore, the importance of quality assurance in conveyor components manufacturing cannot be overstated. Manufacturers must adhere to strict quality control standards to ensure that their components meet industry regulations and customer expectations. This includes rigorous testing and certification processes that guarantee the reliability and safety of the products. Companies with a proven track record of quality are more likely to earn the trust of their customers, leading to long-term relationships and repeat business.

In conclusion, conveyor components manufacturers are essential players in the industrial landscape, driving efficiency and innovation across various sectors. Their ability to adapt to changing market demands, embrace new technologies, and uphold sustainability practices positions them as key contributors to the future of manufacturing and logistics. As industries continue to evolve, the role of conveyor components manufacturers will only become more critical, ensuring that businesses can operate smoothly and efficiently in an increasingly competitive environment. Embracing collaboration, innovation, and quality will be paramount for manufacturers to thrive in this dynamic field.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025