Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 26, 2025 04:44

Back to list

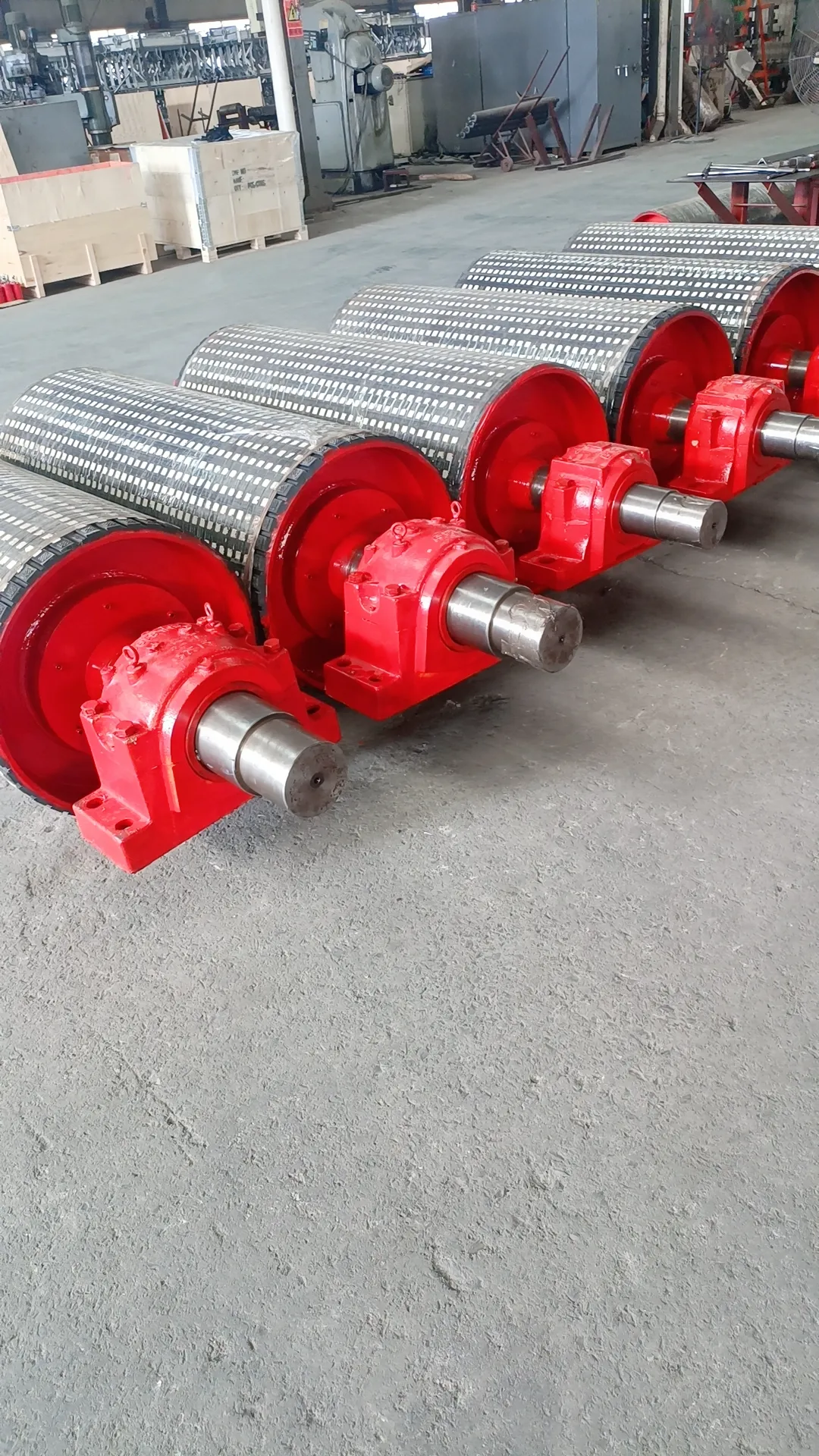

conveyor component

The world of conveyor components is an intriguing landscape, filled with innovation, engineering excellence, and industry-defining applications. As the backbone of many industrial operations, conveyor components play a critical role in ensuring efficient, safe, and reliable movement of materials across various sectors, from manufacturing and logistics to mining and agriculture. Leveraging years of hands-on experience, this article delves deep into the nuances of conveyor components, providing professional insights, authoritative guidance, and an honest perspective into their significance within the modern industrial milieu.

The credibility of conveyor components is further enhanced by their robust compliance with industry standards. For instance, components undergoing rigorous testing and certification processes ensure safety and performance benchmarks are met. Additionally, reputable manufacturers offer extensive warranties and support, underscoring their confidence in the durability and reliability of their products — a testament to the trustworthiness that industry players seek. Authoritativeness in conveyor components is also established through extensive industry collaboration and customer feedback loops. By working closely with end-users, conveyor component manufacturers can identify operational bottlenecks and innovate solutions tailored to precise needs. These collaborations not only spur technological advancements but also cultivate a sense of community within the industry, where experience and expertise are shared. Reflecting on real-world applications underscores the indispensable nature of conveyor components. In the bustling world of e-commerce and warehousing, for instance, conveyors are the circulatory system, channeling goods through various stages of sorting and shipping. The efficiency of this operation hinges on the quality and precision of its conveyor components. Similarly, in the heavy-duty realm of mining, conveyor systems endure extreme conditions and massive loads. Here, the robustness and engineering excellence of components are paramount, highlighting the necessity for expertise-driven solutions that can withstand the harshest environments. In conclusion, conveyor components represent more than just the sum of their parts; they are a testament to human ingenuity and collaborative industry efforts. From material selection and process automation to standard compliance and innovation, each component plays a crucial role in the overarching goal of enhancing productivity and ensuring safety. For industries reliant on the seamless movement of goods, investing in high-quality conveyor components isn't merely an operational decision; it is a commitment to excellence and a pledge to uphold standards that align with Experience, Expertise, Authoritativeness, and Trustworthiness. These components, with their unseen yet profound impact, continually propel industries forward, ensuring the vital flow of commerce and resources worldwide.

The credibility of conveyor components is further enhanced by their robust compliance with industry standards. For instance, components undergoing rigorous testing and certification processes ensure safety and performance benchmarks are met. Additionally, reputable manufacturers offer extensive warranties and support, underscoring their confidence in the durability and reliability of their products — a testament to the trustworthiness that industry players seek. Authoritativeness in conveyor components is also established through extensive industry collaboration and customer feedback loops. By working closely with end-users, conveyor component manufacturers can identify operational bottlenecks and innovate solutions tailored to precise needs. These collaborations not only spur technological advancements but also cultivate a sense of community within the industry, where experience and expertise are shared. Reflecting on real-world applications underscores the indispensable nature of conveyor components. In the bustling world of e-commerce and warehousing, for instance, conveyors are the circulatory system, channeling goods through various stages of sorting and shipping. The efficiency of this operation hinges on the quality and precision of its conveyor components. Similarly, in the heavy-duty realm of mining, conveyor systems endure extreme conditions and massive loads. Here, the robustness and engineering excellence of components are paramount, highlighting the necessity for expertise-driven solutions that can withstand the harshest environments. In conclusion, conveyor components represent more than just the sum of their parts; they are a testament to human ingenuity and collaborative industry efforts. From material selection and process automation to standard compliance and innovation, each component plays a crucial role in the overarching goal of enhancing productivity and ensuring safety. For industries reliant on the seamless movement of goods, investing in high-quality conveyor components isn't merely an operational decision; it is a commitment to excellence and a pledge to uphold standards that align with Experience, Expertise, Authoritativeness, and Trustworthiness. These components, with their unseen yet profound impact, continually propel industries forward, ensuring the vital flow of commerce and resources worldwide.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS