Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Understanding the Key Features and Functions of Conveyor Components

Understanding Conveyor Components The Backbone of Efficient Material Handling

In today's fast-paced industrial landscape, the need for efficient material handling systems has never been more critical. Conveyor systems, a cornerstone of modern logistics and manufacturing operations, have revolutionized the way products are moved from one point to another. At the heart of these systems are various conveyor components, each playing a vital role in ensuring that materials are transported safely and effectively. In this article, we will explore the key conveyor components, their functions, and their importance in facilitating seamless operations.

1. Belts

One of the most recognizable parts of any conveyor system is the belt. Conveyor belts can be made from several materials, including rubber, plastic, and metal, depending on the application requirements. They are designed to transport materials and products horizontally or at an incline. The choice of belt material and design is critical, as it affects the system's overall efficiency, load capacity, and durability. For instance, a heavy-duty rubber belt may be used for transporting bulky items in a mining operation, while a slick plastic belt may be more suitable for moving lightweight packages in a warehouse setting.

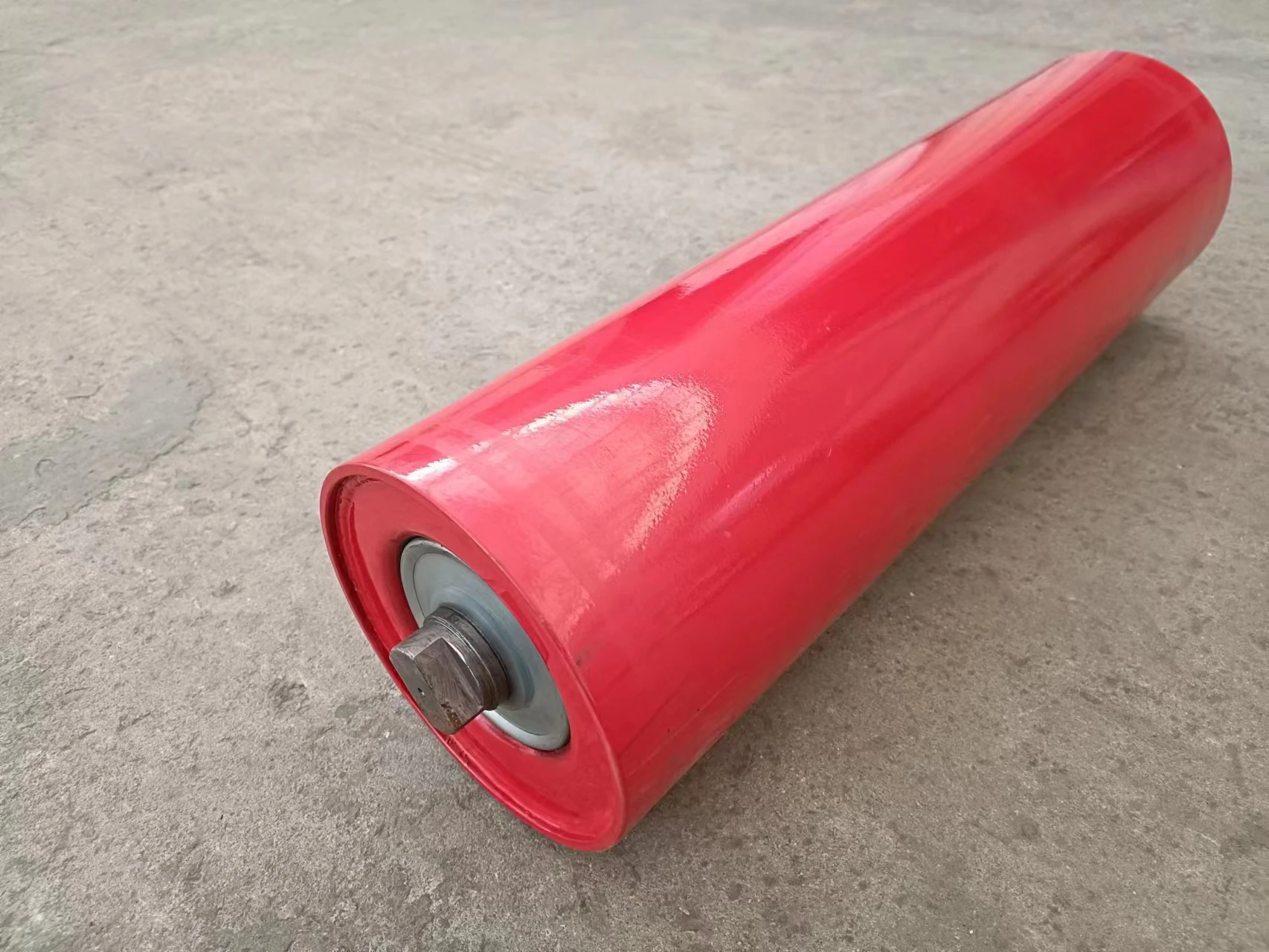

2. Rollers

Rollers are essential components that support the conveyor belt and aid in its movement. They are typically mounted on frames and help facilitate the movement of the belt by reducing friction. Rollers come in various types, including idler rollers, which support the belt's weight, and drive rollers, which are powered to move the belt. The diameter and material of the rollers can significantly impact the system's efficiency; larger rollers can handle heavier loads, while those made of durable materials can withstand wear and tear over time.

3. Motors and Drives

Motors and drives are the powerhouses of conveyor systems. The motor provides the necessary energy to drive the rollers and move the belt. Depending on the design of the conveyor system, this can involve several configurations, such as direct drives, gear reducers, or variable frequency drives (VFDs). The choice of motor will depend on the required speed, load capacity, and operating environment. For example, a VFD allows for adjustable speeds, enabling more flexibility in material handling processes, which is especially beneficial in applications where product flow varies.

conveyor component

4. Chassis and Frames

The chassis and frames are the structural elements that support the entire conveyor system. They ensure stability and allow for easy installation and integration into existing operations. Typically made from steel or aluminum, the frames must be designed to withstand various loads while providing the necessary support to the conveyor belt and its components. Proper frame design takes into account not only the weight of the materials being transported but also the dynamic forces generated during operation.

Modern conveyor systems are increasingly being integrated with advanced sensors and control systems, contributing to heightened efficiency and safety. Sensors can detect the presence of products on the conveyor, monitor speed and direction, and even analyze the belt's condition. Control systems can automate various functions, including starting and stopping the belt, adjusting speeds, and integrating with other equipment, such as sorting machines or robotic arms. This level of automation can greatly reduce the need for manual oversight, leading to faster operations and reduced labor costs.

6. Safety Features

Safety is paramount in any industrial setting, and conveyor systems are no exception. Various safety features can be integrated into conveyor components, including emergency stop buttons, safety guards, and light curtains. These elements work together to protect workers from potential hazards associated with moving parts and heavy loads. Ensuring that these safety mechanisms are functional and compliant with regulatory standards is essential to maintaining a safe work environment.

Conclusion

Conveyor components are integral to the efficiency and reliability of material handling systems across various industries. Understanding the roles of belts, rollers, motors, frames, sensors, and safety features allows businesses to optimize their conveyor systems for peak performance. As technology continues to evolve, the future of conveyor systems promises even more innovative solutions to enhance material handling, meet increasing consumer demands, and improve operational efficiency. Whether in manufacturing, logistics, or distribution, the significance of conveyor components cannot be overstated; they are, indeed, the backbone of modern workflows.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025