Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Innovative Solutions for Efficient Conveyor System Components and Design

The Importance of Conveyor Components in Modern Industries

In the ever-evolving landscape of modern manufacturing and material handling, conveyor systems have become an integral part of the production process. At the heart of these systems are conveyor components, the unsung heroes that ensure the seamless operation of conveyors in various industries. This article delves into the critical roles played by these components, the different types available, and their significance in enhancing operational efficiency.

Conveyor systems are designed to move materials from one point to another with minimal human intervention. They can be found in diverse settings, from large warehouses to manufacturing plants, and even airports. The efficiency of these systems largely depends on the quality of their components, which include belts, rollers, pulleys, motors, controllers, and supports, among others.

1. Types of Conveyor Components

One of the primary components of any conveyor system is the belt. Conveyor belts are available in various materials, including rubber, plastic, metal, and fabric, each suited for specific applications. For instance, rubber belts are often used in heavy-duty applications due to their durability, while lighter plastic belts are employed in food handling and packaging.

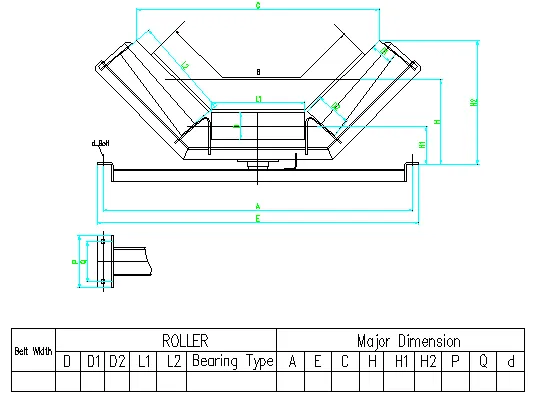

Rollers are another vital component, serving as the support structure for the conveyor belt. They facilitate the smooth movement of the belt and help reduce friction, which is crucial for efficient operation. Depending on the type of conveyor, rollers can come in different designs powered to move loads or idler rollers which simply support the belt.

Pulleys and motors are essential for the conveyor's drive system. Pulleys help to redirect and stabilize the belt while also transmitting power from the motor. The choice of motor is equally important, as it needs to provide sufficient power to move the load while minimizing energy consumption. Variable frequency drives (VFDs) are commonly used to control the speed and torque of the motors, allowing for more precise operation.

2. The Role of Conveyor Components in Efficiency

conveyor component

The design and quality of conveyor components directly impact the overall efficiency of the conveyor system. High-quality components reduce downtime caused by breakdowns and increase system reliability. For example, using durable belts and rollers can minimize wear and tear, leading to longer service life and reduced maintenance costs.

Moreover, well-designed conveyor components can enhance safety within the workplace

. Implementing features such as emergency stop buttons and safety guards can prevent accidents, ensuring a safer working environment. Additionally, modern conveyor systems often incorporate sensors and automated controls, which can provide real-time data on system performance and alert operators to potential issues before they escalate.3. The Future of Conveyor Components

As industries continue to embrace automation and smart technology, the future of conveyor components looks promising. Innovations such as IoT-enabled sensors allow for predictive maintenance, helping businesses forecast potential failures and avoid costly downtimes. Furthermore, advancements in materials science are leading to the development of lighter yet stronger components, resulting in improved energy efficiency and reduced operational costs.

Sustainability is another significant trend influencing the design of conveyor components. Manufacturers are increasingly focusing on eco-friendly materials and energy-efficient systems to minimize their environmental impact. For instance, the adoption of recycled materials for conveyor belts is gaining traction as companies strive to meet sustainability goals.

Conclusion

In conclusion, conveyor components play a crucial role in the functionality and efficiency of conveyor systems across various industries. Their importance cannot be overstated, as they directly influence productivity, safety, and operational costs. As technology advances, the evolution of these components will likely continue, offering further enhancements that meet the ever-growing demands of modern industry. Investing in high-quality conveyor components is not only critical for immediate efficiency but also essential for fostering long-term sustainability and success in an increasingly competitive marketplace.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025