Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 20, 2025 15:41

Back to list

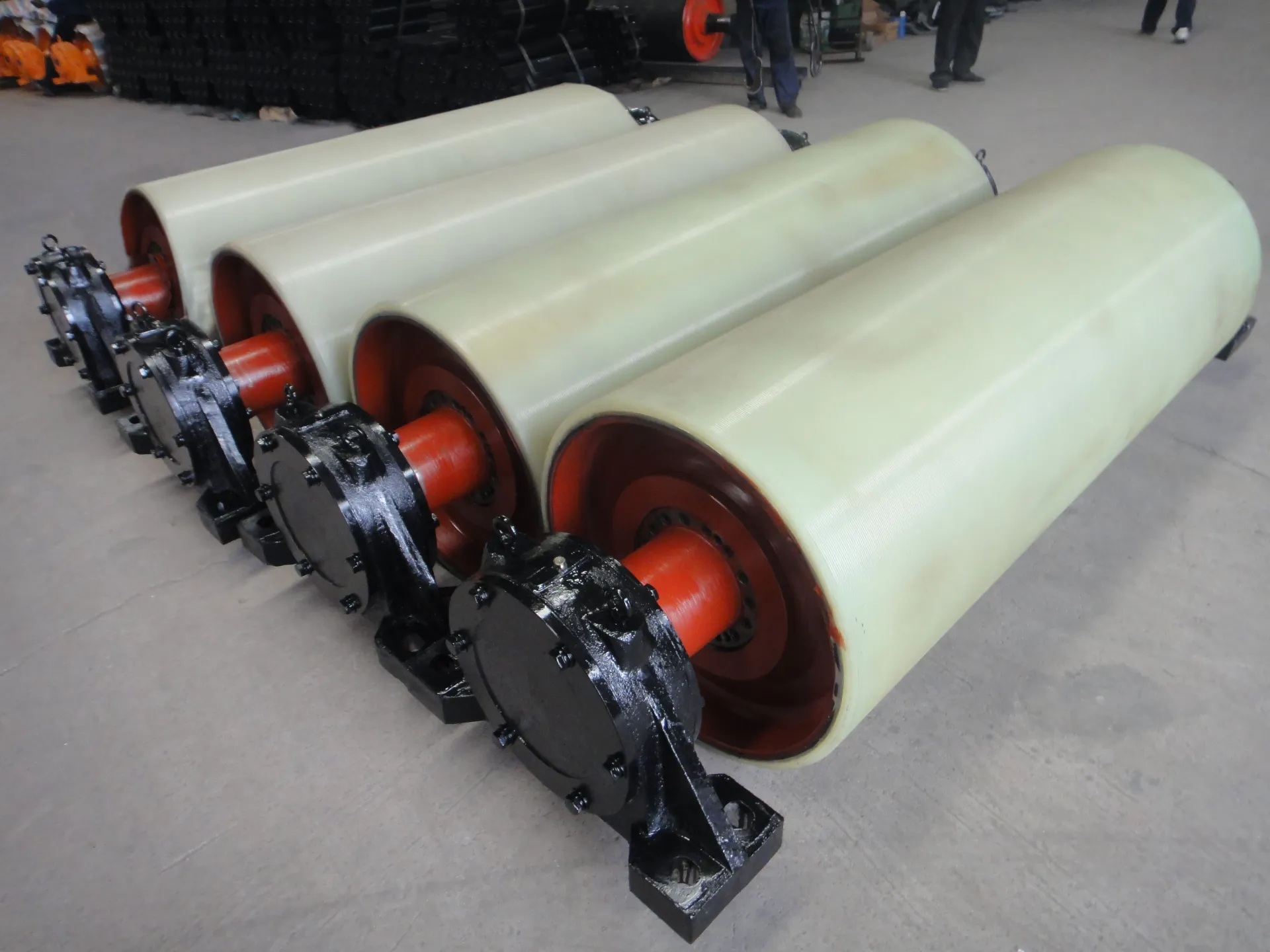

Guide Roller

Conveyor carrying rollers play a pivotal role in ensuring the smooth and efficient operation of conveyor systems. When selecting these essential components, experience, expertise, authoritativeness, and trustworthiness are crucial in making informed purchasing decisions.

When it comes to authoritativeness, investing in rollers from reputable manufacturers ensures a level of quality and dependability. Established brands have spent years honing their design and manufacturing processes, often leading to innovations that set industry standards. Their reputation is built on consistent product quality and service, both of which are crucial in minimizing downtime and maintenance costs in a demanding industrial setting. Additionally, considering context from a trusted source, like customer reviews and case studies, can provide practical insights into the performance of specific conveyor carrying rollers. Platforms with transparent customer feedback can be invaluable. Real-world testimonials can highlight issues unnoticed during the purchase phase but critical to long-term use. Trustworthy reviews and detailed case studies add another layer of confidence when selecting a product that must perform reliably over an extended period. Maintenance and after-sales support are also critical components of a trustworthy offering. A supplier that provides comprehensive after-sales service ensures that any operational issues with the rollers are swiftly addressed. This level of commitment not only saves time but also secures your conveyor system’s efficiency and longevity. Maintaining a relationship with a supplier known for its responsive after-sales support can significantly reduce potential risks associated with operation downtimes. In conclusion, the selection of the right conveyor carrying roller transcends the basic specifications. Drawing from experience and expertise within the field allows one to make informed decisions. Opting for products from authoritative manufacturers ensures quality and durability, while trusted sources of information further guide the final decision-making process. By integrating these aspects into your purchasing strategy, you not only optimize the performance and efficiency of your conveyor system but also achieve long-term operational success and reliability.

When it comes to authoritativeness, investing in rollers from reputable manufacturers ensures a level of quality and dependability. Established brands have spent years honing their design and manufacturing processes, often leading to innovations that set industry standards. Their reputation is built on consistent product quality and service, both of which are crucial in minimizing downtime and maintenance costs in a demanding industrial setting. Additionally, considering context from a trusted source, like customer reviews and case studies, can provide practical insights into the performance of specific conveyor carrying rollers. Platforms with transparent customer feedback can be invaluable. Real-world testimonials can highlight issues unnoticed during the purchase phase but critical to long-term use. Trustworthy reviews and detailed case studies add another layer of confidence when selecting a product that must perform reliably over an extended period. Maintenance and after-sales support are also critical components of a trustworthy offering. A supplier that provides comprehensive after-sales service ensures that any operational issues with the rollers are swiftly addressed. This level of commitment not only saves time but also secures your conveyor system’s efficiency and longevity. Maintaining a relationship with a supplier known for its responsive after-sales support can significantly reduce potential risks associated with operation downtimes. In conclusion, the selection of the right conveyor carrying roller transcends the basic specifications. Drawing from experience and expertise within the field allows one to make informed decisions. Opting for products from authoritative manufacturers ensures quality and durability, while trusted sources of information further guide the final decision-making process. By integrating these aspects into your purchasing strategy, you not only optimize the performance and efficiency of your conveyor system but also achieve long-term operational success and reliability.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS