Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor brackets

Understanding Conveyor Brackets Essential Components for Efficient Material Handling

In today's fast-paced industrial environment, the efficiency of material handling plays a pivotal role in the overall productivity of manufacturing, packaging, and distribution processes. One essential component that is often overlooked but crucial in this domain is the conveyor bracket. These brackets form the backbone of conveyor systems, ensuring stability, support, and proper alignment of various conveyor components. This article delves into the importance of conveyor brackets, their types, applications, and best practices for maintenance.

What Are Conveyor Brackets?

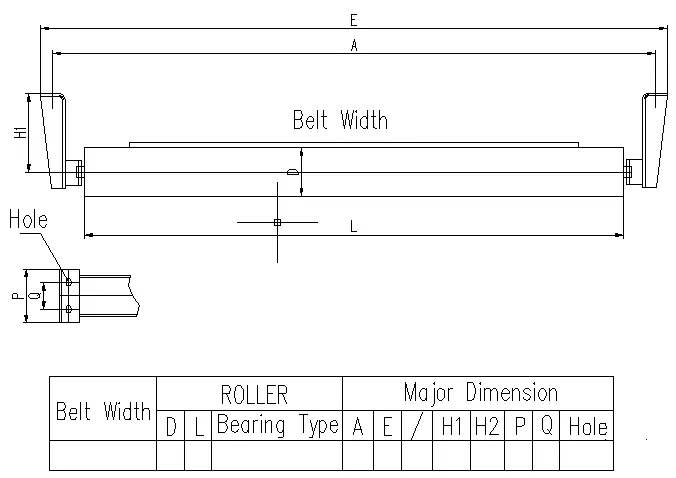

Conveyor brackets are structural elements designed to support and stabilize conveyor belts and other related components, such as rollers, pulleys, and motors. They are typically made from strong materials like steel or aluminum to withstand heavy loads and dynamic forces during operation. Properly installed conveyor brackets ensure that the conveyor system operates smoothly and efficiently, thus minimizing the risk of breakdowns or material spills.

Types of Conveyor Brackets

There are several types of conveyor brackets, each serving specific purposes

1. Support Brackets These brackets hold the conveyor frame and provide the necessary support to the entire structure. They are crucial for maintaining the correct height and angle of the conveyor.

2. Idler Brackets These are used to secure idler rollers, which help to guide the conveyor belt and maintain tension. Idler brackets are designed to accommodate the lateral movement of the belt, ensuring smooth operation.

3. Mounting Brackets Used to attach various components like motors and gearboxes to the conveyor frame, mounting brackets are essential for integrating power transmission mechanisms in the system.

4. Belt Tensioning Brackets These brackets allow for the adjustment of belt tension, which is critical for preventing slippage and ensuring optimal performance.

Applications of Conveyor Brackets

Conveyor brackets find applications across various industries, including

conveyor brackets

- Manufacturing In assembly lines, conveyor brackets support conveyor belts that transport products from one station to another. This seamless movement enhances productivity and reduces labor costs.

- Food Processing Conveyor systems in food processing plants often utilize brackets to ensure hygiene and efficiency. The brackets are designed to withstand harsh cleaning chemicals and high temperatures.

- Distribution and Warehousing In logistics, conveyor brackets play a vital role in automated sorting systems, allowing for the efficient movement of packages and goods.

Best Practices for Installation and Maintenance

To maximize the lifespan and efficiency of conveyor brackets, it is essential to adhere to best practices

1. Proper Installation Ensure that brackets are installed according to the manufacturer's specifications. Misalignment can lead to increased wear and tear on the system.

2. Regular Inspections Conduct routine inspections to check for signs of wear, corrosion, or damage. Early detection of issues can prevent costly downtime.

3. Lubrication Apply lubricants to moving parts and ensure that all connections are tight. This reduces friction and prolongs the life of both the brackets and the conveyor system.

4. Load Management Be aware of the weight and type of materials being transported. Overloading a conveyor can put excessive strain on brackets, leading to failure.

Conclusion

Conveyor brackets may not always be in the spotlight, but their role in maintaining the efficiency and reliability of conveyor systems is undeniable. Understanding the different types of brackets, their applications, and maintenance practices can significantly enhance the performance of material handling systems. A well-maintained conveyor system, supported by robust brackets, is essential for any organization looking to streamline operations and improve productivity. By investing in quality conveyor brackets and adhering to best practices, businesses can ensure smooth, efficient operations for years to come.