Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Brackets for Conveyor System Support and Stability

Understanding Conveyor Brackets Importance, Types, and Applications

Conveyor systems are essential in various industries for transporting materials efficiently and safely. At the heart of these systems lie conveyor brackets, which play a pivotal role in maintaining the structure and functionality of conveyors. Understanding conveyor brackets—what they are, their types, and their applications—offers valuable insight into their significance in industrial operations.

What Are Conveyor Brackets?

Conveyor brackets are support structures designed to hold and stabilize components of a conveyor system. They ensure that various parts, such as belts, rollers, and pulleys, are securely positioned and aligned, preventing misalignment that could lead to operational inefficiencies or equipment failure. Brackets can be manufactured from several materials, including steel, aluminum, and plastic, depending on the specific needs of the conveyor system.

Importance of Conveyor Brackets

The role of conveyor brackets cannot be overstated. They provide the necessary support to prevent sagging or bending of conveyor components under heavy loads. Properly installed brackets help maintain the correct tension on belts, which is crucial for smooth operation and efficiency. Furthermore, brackets contribute to the overall safety of the conveyor system. Well-structured support reduces the risk of accidents, ensuring that employees working near or with conveyor systems remain safe.

The longevity and performance of conveyor systems are also significantly influenced by the quality of the brackets. High-quality, durable brackets can withstand harsh industrial environments, including exposure to dirt, moisture, and extreme temperatures. Conversely, substandard materials may corrode or wear down quickly, leading to frequent replacements and costly downtime.

Types of Conveyor Brackets

Conveyor brackets come in various styles and designs, each tailored to specific applications and requirements. Some common types include

1. Mounting Brackets These are used to attach rollers, pulleys, or other components to the conveyor frame. They ensure that these parts are securely anchored and positioned for optimal function.

conveyor brackets

2. Support Brackets These brackets provide additional support to the conveyor structure, especially in long stretches where sagging might occur. They enhance the stability of the entire system, ensuring a smooth and consistent operation.

3. Adjustable Brackets Designed for versatility, adjustable brackets allow for height and angle modifications. This feature is particularly useful for systems that require frequent reconfigurations or alignments.

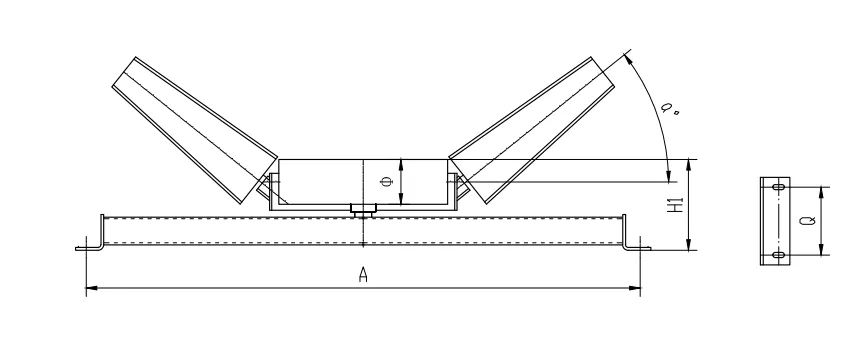

4. Idler Brackets Specifically used for idler rollers, these brackets help in maintaining the correct alignment of the belt as it travels through the conveyor system. They play a crucial role in reducing friction and wear on the belt.

5. Custom Brackets In some cases, standard brackets may not meet specific operational needs. Custom brackets can be designed and manufactured to suit unique applications, ensuring that all components function seamlessly.

Applications of Conveyor Brackets

Conveyor brackets find applications across diverse industries. In manufacturing, they support the continuous flow of products along assembly lines, enabling efficient production processes. In warehousing, brackets help in organizing and moving inventory smoothly, significantly speeding up order fulfillment.

In the food and beverage industry, specially designed brackets resist corrosion and contaminants, ensuring that products are transported safely without compromising hygiene. Similarly, in the mining and materials handling sectors, durable brackets are vital due to the heavy loads and harsh environments.

Conclusion

Conveyor brackets are a fundamental component of conveyor systems, serving as the backbone that maintains structural integrity and operational efficiency. Various types of brackets cater to specific needs, ensuring that conveyor systems can function effectively across multiple industries. Understanding the importance and applications of conveyor brackets not only helps in selecting the right ones for a specific need but also underscores their role in enhancing productivity, safety, and longevity of conveyor systems. As industries continue to evolve and demand for automation increases, the design and technology behind conveyor brackets will undoubtedly play a critical part in shaping the future of material handling and transport systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025