Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Conveyor Bracket Solutions for Efficient Material Handling and Installation Techniques

Understanding Conveyor Brackets Essential Components for Efficient Systems

Conveyor systems are integral to the logistics and manufacturing sectors, enabling the smooth transport of goods and materials from one location to another. Within these systems, various components play critical roles in ensuring both functionality and safety. Among these components, conveyor brackets are essential elements that support the overall structure and efficiency of conveyor systems. In this article, we will explore the significance of conveyor brackets, their types, applications, and the factors to consider when selecting them.

What are Conveyor Brackets?

Conveyor brackets are mounting devices that hold and support different parts of a conveyor system, including belts, rollers, and frames. They are designed to provide stability and ensure that all components function harmoniously. Moreover, they help to minimize vibration and misalignment, which can lead to operational inefficiencies. Conveyor brackets can be made from various materials, including steel, aluminum, and plastic, depending on the specific requirements of the application.

Types of Conveyor Brackets

There are several types of conveyor brackets, each suited for different applications

1. Standard Brackets These are the most commonly used conveyor brackets. They often come in various shapes and sizes and are employed in general-purpose applications where medium load capacities are required.

2. Heavy-Duty Brackets Designed for industrial applications, heavy-duty brackets are built to withstand substantial loads and were typically made from robust materials. These brackets are used in environments where heavy materials are transported, such as construction and mining.

3. Adjustable Brackets These brackets offer versatility as they can be modified to accommodate different heights or angles. They are especially useful in systems that require frequent adjustments or reconfigurations.

4. Specialized Brackets Some applications may require brackets designed for specific tasks or environments. For instance, brackets for food-grade conveyors are designed to meet cleanliness and hygiene standards, while those used in corrosive environments may be made from stainless steel to resist rust.

Applications of Conveyor Brackets

Conveyor brackets find applications across various industries

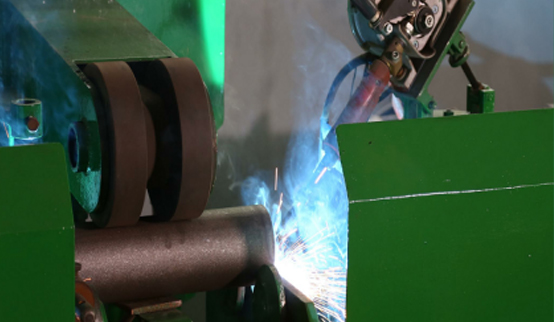

conveyor brackets

- Manufacturing In manufacturing facilities, conveyor systems equipped with appropriate brackets streamline production processes, helping to move parts and products efficiently along assembly lines

.- Warehousing and Distribution Conveyor brackets support systems that facilitate the storage and shipping of products, enhancing the speed and accuracy of order fulfillment.

- Food Processing In food processing plants, conveyor brackets assist in transporting products while ensuring compliance with safety and hygiene regulations.

- Mining and Construction These industries utilize heavy-duty conveyor brackets to support systems that handle bulk materials, ensuring durability and reliability in harsh environments.

Factors to Consider When Selecting Conveyor Brackets

When it comes to selecting conveyor brackets for specific applications, several factors should be considered

1. Load Capacity Ensure that the brackets can support the weight of materials being transported.

2. Material The material of the brackets should be chosen based on the application environment, such as susceptibility to corrosion or the necessity for hygiene.

3. Compatibility Brackets must be compatible with other components of the conveyor system to ensure seamless integration.

4. Adjustability If the application requires frequent changes or adjustments, selecting brackets that offer flexibility is crucial.

In conclusion, conveyor brackets play a vital role in the efficiency and stability of conveyor systems across various industries. By understanding their types, applications, and selection criteria, businesses can improve their conveyor system performance and reduce operational costs. As industries continue to evolve, the importance of reliable and effective conveyor brackets will only grow, underscoring their critical role in modern logistics and manufacturing.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025