Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt scraper

Understanding the Conveyor Belt Scraper A Vital Component in Material Handling

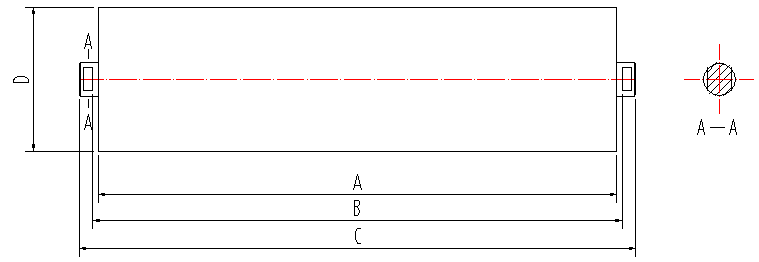

The conveyor belt scraper is a crucial component in the operation of conveyor systems, widely used across various industries including mining, manufacturing, and logistics. Its primary function is to maintain the cleanliness of the conveyor belt, thus enhancing the efficiency and lifespan of the belt as well as the overall conveyor system.

What is a Conveyor Belt Scraper?

A conveyor belt scraper is a specialized device designed to remove material that adheres to the surface of the conveyor belt. This adhering material can include dirt, dust, or any residual product that may accumulate during the transport process. Over time, such buildup can hinder the smooth operation of the conveyor system and even lead to significant operational issues, including reduced efficiency and increased wear on the belt.

Types of Conveyor Belt Scrapers

There are two main types of conveyor belt scrapers primary scrapers and secondary scrapers

.- Primary Scrapers These are positioned at the discharge point of the conveyor system, where the bulk material is deposited. Their main purpose is to remove as much material as possible before the conveyor belt returns to its idle position. Primary scrapers are often made of durable materials, such as polyurethane or rubber, to withstand the abrasive nature of the materials being transported.

- Secondary Scrapers These are placed further along the conveyor belt and serve to catch any residual materials that the primary scraper may have missed. They provide an additional layer of cleaning, ensuring that the belt remains clean and reducing the chance of material carryback that could lead to potential contamination or operational hazards.

conveyor belt scraper

Importance of Conveyor Belt Scrapers

The importance of conveyor belt scrapers cannot be overstated. Here are several key benefits they provide

1. Enhancing Efficiency By keeping the conveyor belt clean, scrapers ensure that the belt operates smoothly without unnecessary friction or drag. This leads to improved throughput and operational efficiency.

2. Reducing Downtime Regular maintenance and cleaning of the conveyor belt can significantly reduce downtime. Material buildup can cause wear and tear, ultimately leading to costly breakdowns and repairs. A well-functioning scraper minimizes these risks.

3. Environmental Considerations Effective scrapers help in reducing material loss, which not only protects financial investments but also enhances environmental sustainability. Lost material can contribute to waste, whereas maintaining a clean system can lead to more responsible resource utilization.

4. Safety Enhancements A clean conveyor belt reduces the risk of accidents related to slipping or tripping hazards created by material buildup around the conveyor area. This promotes a safer working environment for all employees.

Conclusion

In conclusion, the conveyor belt scraper is an indispensable element of conveyor systems. Its role in maintaining cleanliness, enhancing efficiency, and promoting safety demonstrates its value across various industries. As technology advances, innovations in scraper design and materials are likely to emerge, further improving their effectiveness and efficiency in an ever-evolving industrial landscape. For companies that rely heavily on conveyor systems, investing in quality scrapers should be a priority to ensure seamless operations and sustainable practices.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025