Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Affordable Conveyor Belt Roller Pricing and Options for Your Needs

Understanding Conveyor Belt Roller Prices A Comprehensive Overview

Conveyor belt rollers are essential components in material handling systems, playing a crucial role in the efficient transport of goods and materials across various industries. From manufacturing to warehousing, these rollers help ensure that operations run smoothly, enabling businesses to maintain productivity. However, the price of conveyor belt rollers can vary significantly based on several factors. In this article, we will explore the determinants of conveyor belt roller prices, the types of rollers available, and considerations for purchasing.

Factors Influencing Conveyor Belt Roller Prices

1. Material and Construction The price of conveyor belt rollers is heavily influenced by the materials used in their construction. Common materials include steel, aluminum, and high-density polyethylene (HDPE). Steel rollers are often more expensive due to their durability and strength, making them suitable for heavy-duty applications. Conversely, lighter materials like aluminum or plastic may be cheaper but are typically used for lighter loads.

2. Size and Design The dimensions of the roller also play a critical role in pricing. Larger rollers, which can support heavier loads, tend to cost more than smaller ones. Additionally, specialized designs, such as those engineered for specific applications (e.g., inclined or curved conveyor systems), can increase costs due to the need for custom manufacturing.

3. Load Capacity The load capacity of a roller directly affects its price. High-capacity rollers designed for heavy loads will generally be more expensive than standard capacity rollers. Choosing the right load capacity is essential for ensuring the longevity of both the roller and the conveyor system.

4. Brand and Quality Brand reputation influences price as well. Established brands that are known for their high-quality products may charge a premium. Investing in well-regarded brands can often result in lower operational costs in the long run, as these products tend to have longer lifespans and require less frequent replacement.

5. Market Conditions Economic factors, such as the cost of raw materials and supply chain issues, can impact the pricing of conveyor belt rollers. Fluctuations in global steel prices, for instance, can lead to changes in roller costs. Additionally, during periods of high demand, suppliers may increase prices.

Types of Conveyor Belt Rollers

1. Idler Rollers These are used to support the conveyor belt and load. They are available in various sizes and types, including impact rollers that help absorb shocks from heavy loads and training rollers that keep the belt aligned.

conveyor belt roller price

2. Drive Rollers These rollers are connected to the drive mechanism and are responsible for moving the belt. They are typically more expensive due to their additional features that facilitate power transmission.

3. Return Rollers As the name suggests, return rollers support the return side of the conveyor belt. They are generally less expensive than drive rollers but still essential for maintaining the conveyor system's integrity.

4. Specialty Rollers These include rollers designed for specific applications, such as food-grade rollers or corrosion-resistant models used in harsh environments. Specialty rollers tend to be more costly due to their specialized materials and engineering.

Considerations for Purchasing Conveyor Belt Rollers

When purchasing conveyor belt rollers, it is essential to consider your specific application requirements. Start by analyzing the load weight, belt speed, and environmental conditions. Additionally, consider the lifecycle cost of the rollers, including maintenance and replacement. Cheaper rollers might seem attractive initially, but if they do not last as long or require frequent servicing, they could end up costing more.

Another vital consideration is alignment with industry standards. Ensure that the rollers you choose meet necessary safety and quality standards relevant to your industry. This will help prevent costly accidents or downtime caused by equipment failure.

Finally, always seek quotes from multiple suppliers to ensure competitive pricing. Many manufacturers may offer bulk discounts or customization options that can help you save money without compromising on quality.

Conclusion

Understanding conveyor belt roller prices involves considering various factors, including materials, size, load capacity, and market conditions. By carefully analyzing your specific needs, industry standards, and supplier options, you can make informed purchasing decisions that lead to operational efficiency and cost savings in your conveyor systems.

-

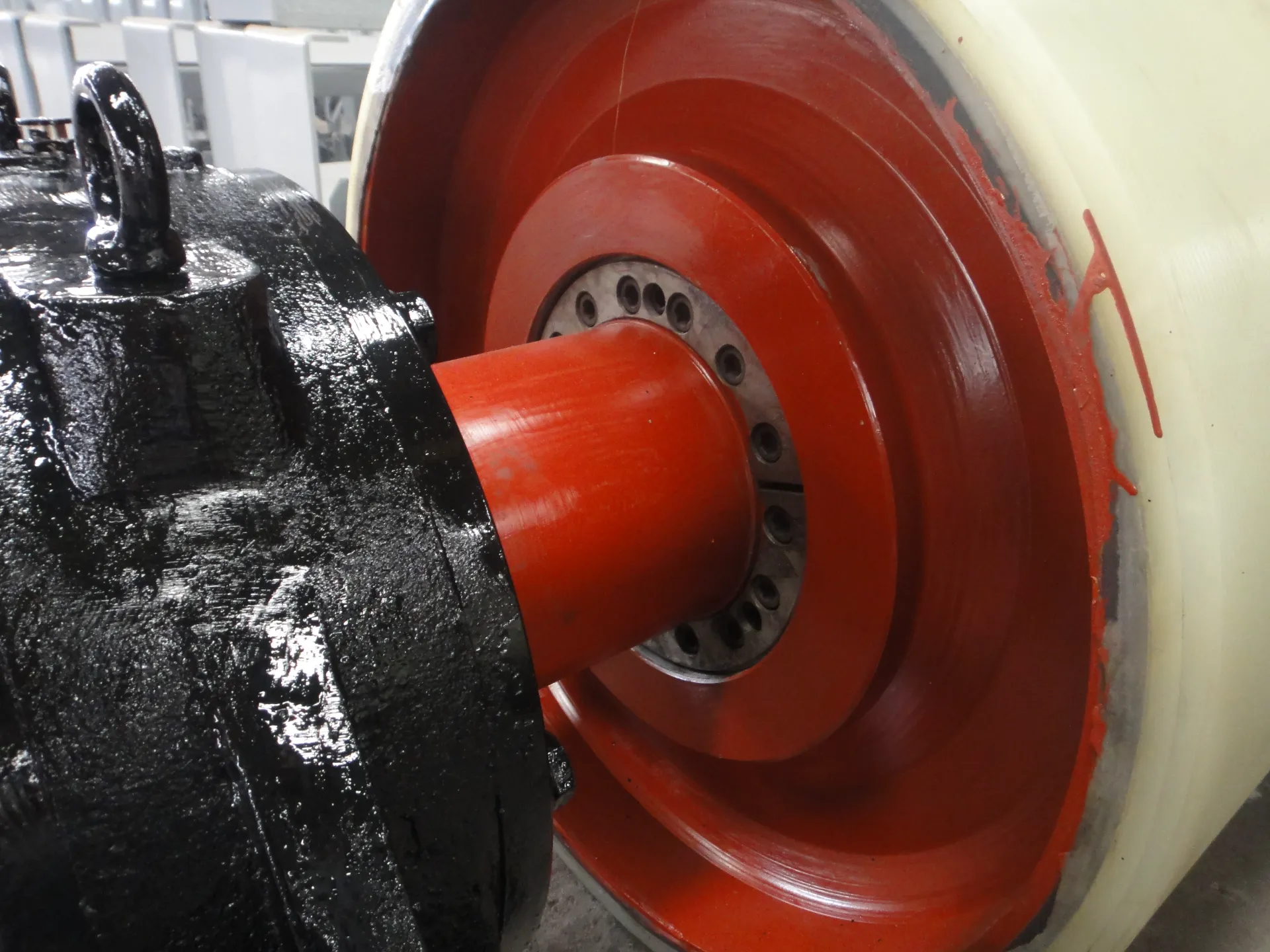

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025