Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Innovative Solutions for Efficient Conveyor Belt Roll Management and Operation

The Evolution and Importance of Conveyor Belt Rolls

Conveyor belts have revolutionized the way industries handle materials, serving as the backbone of production and logistics systems. Among the various components of a conveyor system, the conveyor belt roll stands out as a crucial element responsible for the efficient movement of goods from one point to another. Understanding the evolution, construction, and significance of conveyor belt rolls is essential for appreciating their role in modern manufacturing and distribution.

The Evolution of Conveyor Belt Technology

The origins of conveyor belts can be traced back to the late 18th century. Early systems were simple and relied on manpower or animal power to move goods. However, with the advent of the industrial revolution, mechanical systems began to emerge. The invention of the conveyor belt in the late 19th century marked a significant turning point. Initially utilized in the mining industry for transporting coal and minerals, conveyor belts soon found applications in various sectors, including agriculture, manufacturing, and distribution.

As technology advanced, conveyor systems evolved to become faster, more durable, and more versatile. The introduction of rubber and synthetic materials for conveyor belt construction helped improve their strength and resistance to wear. Today, conveyor belt rolls can be found in numerous industries, from automotive to pharmaceuticals, each designed to cater to specific operational needs.

Understanding Conveyor Belt Rolls

A conveyor belt roll, also known as a spool or drum, is a cylindrical component around which the conveyor belt is wound. Understanding the construction and functioning of these rolls is essential for ensuring efficient operation within a conveyor system.

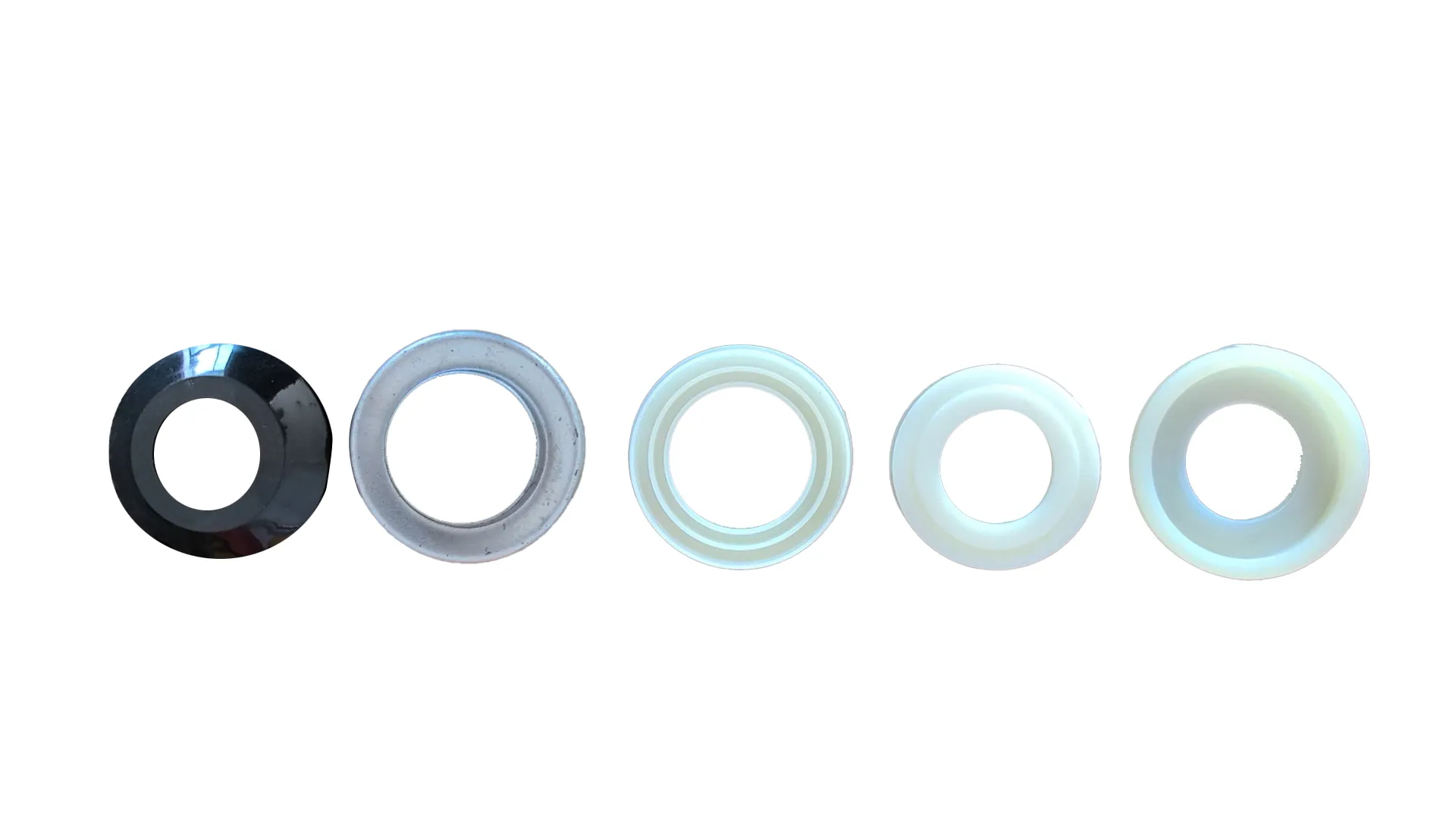

Conveyor belt rolls are usually crafted from durable materials like steel, aluminum, or composite materials, providing necessary strength and longevity. The surface of the roll is often treated or coated to reduce friction and prevent slippage, ensuring smooth operation as the belt moves. The diameter of the roll can significantly influence the performance of the conveyor system; larger rolls reduce wear on the belt and facilitate easier movement, while smaller rolls may enhance maneuverability in tight spaces.

The Role of Conveyor Belt Rolls in Industry

Conveyor belt rolls play an indispensable role in industrial processes

. They contribute to various functions, including the followingconveyor belt roll

1. Efficient Material Handling Conveyor belt rolls facilitate the swift movement of materials from one location to another, minimizing downtime and optimizing workflow. This efficiency is particularly vital in industries with high production demands.

2. Reduced Labor Costs By automating the material transport process, conveyor belt rolls reduce the need for manual handling, thereby lowering labor costs and enhancing worker safety.

3. Flexibility and Customization Conveyor systems equipped with various roll designs can be tailored to meet unique conveyor applications, such as handling heavy loads or moving fragile items. This adaptability makes conveyor belt rolls essential for a diverse range of industries.

4. Maintenance and Longevity High-quality conveyor belt rolls are designed for durability, reducing maintenance requirements and extending the lifespan of the entire conveyor system. Regular maintenance of these rolls, including lubrication and alignment, can prevent costly breakdowns and ensure uninterrupted operations.

Future Trends in Conveyor Belt Roll Technology

As technology continues to advance, the future of conveyor belt rolls is destined for innovation. Smart conveyor systems equipped with sensors and IoT capabilities are beginning to make their mark in the industry. These intelligent systems can monitor the performance of conveyor belt rolls in real time, detecting issues before they escalate and thus minimizing downtime.

Moreover, the emphasis on sustainability is driving manufacturers to develop eco-friendly conveyor solutions. Materials that reduce environmental impact while maintaining durability and performance are increasingly being integrated into conveyor belt roll designs.

Conclusion

Conveyor belt rolls are essential components that underpin efficient material handling systems across various industries. Their evolution has transformed the manufacturing and logistics landscape, providing businesses with the tools needed for increased efficiency and productivity. As technology continues to advance, the development of smarter, more sustainable conveyor belt rolls will undoubtedly shape the future of industry, paving the way for enhanced operational effectiveness and environmental responsibility. Understanding the critical role of these components can help businesses make informed decisions about their material handling processes for years to come.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025