Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 14, 2025 10:57

Back to list

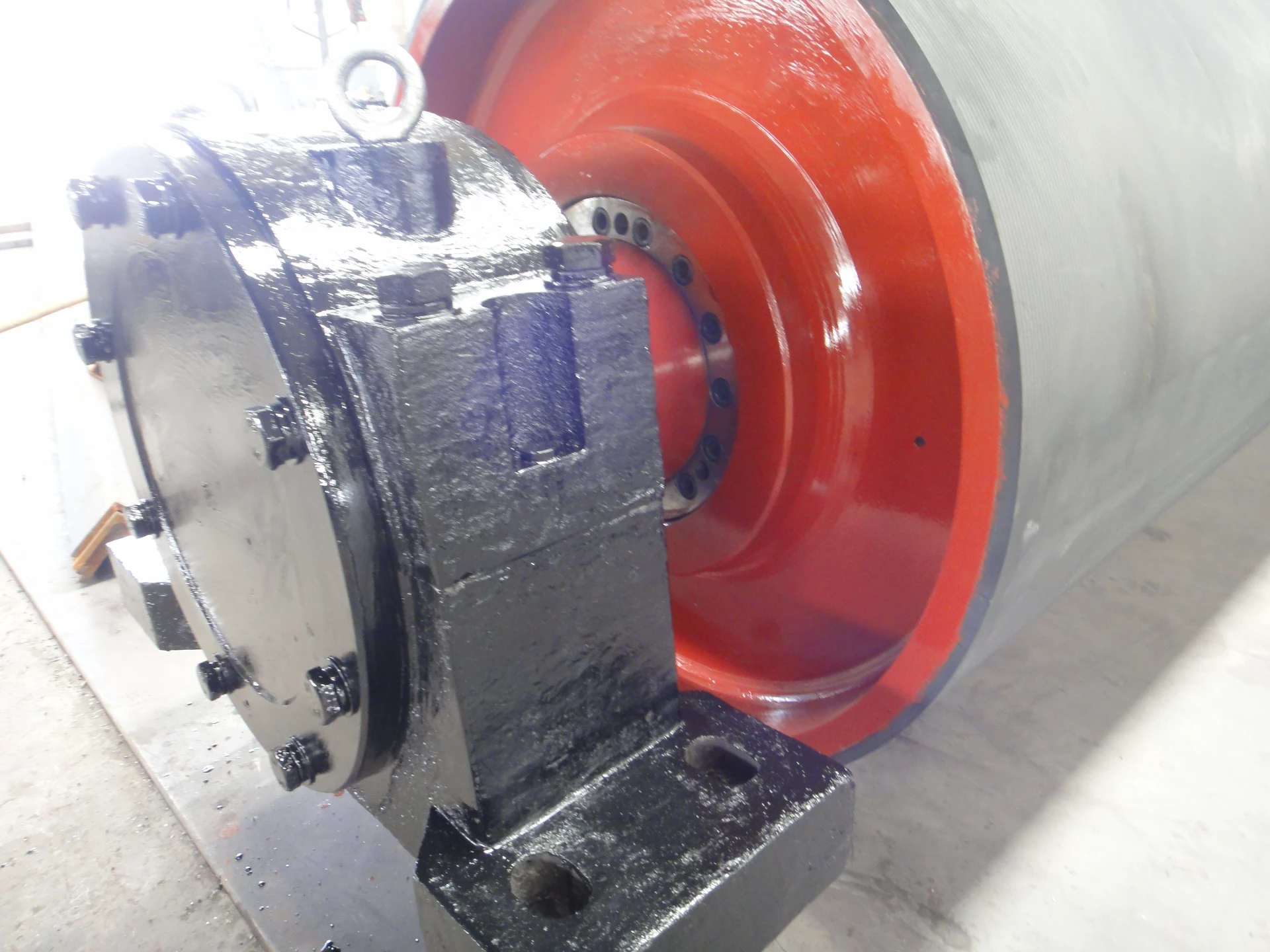

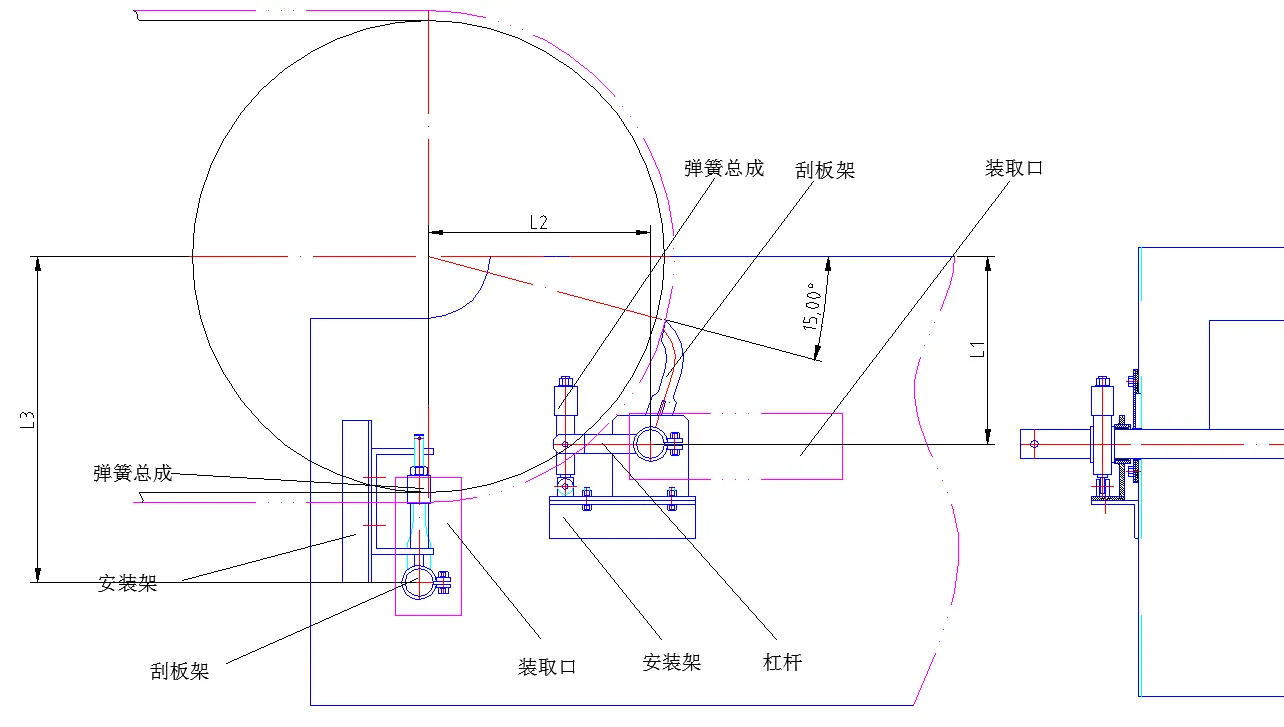

conveyor belt pulley types

Conveyor pulley types play a critical role in the optimal functioning of conveyor systems across various industries. Selecting the right type of pulley can significantly impact the system’s efficiency, reliability, and lifespan. This article explores different conveyor pulley types, enriches understanding from a professional viewpoint, and enhances decision-making for industry experts.

Snub and bend pulleys, while not driving pulleys, assist in tensioning the belt and improving its wrap angle around the driving pulley. This ensures that the belt maintains adequate tension throughout operation, contributing to the system's overall efficiency and durability. When considering material choices, steel is often the material of choice for conveyor pulleys due to its high strength and durability. However, for corrosive or wet environments, stainless steel or other corrosion-resistant materials might be necessary to extend the lifespan of the pulley. For professionals seeking authoritative guidance on pulley selection, evaluating factors such as material handling characteristics, environmental conditions, and belt specifications is paramount. An incorrect choice can lead to premature wear, increased maintenance costs, and even system failures. Expert consultations and adhering to industry best practices can streamline this decision-making process. Evaluating the expertise and experience of manufacturers and suppliers also plays a critical role in this selection journey. Vendors with deep industry knowledge can provide tailored solutions and innovative products meeting specific operational needs, ultimately fostering trust and reliability in their offerings. In conclusion, understanding the various types of conveyor pulleys, each tailored to unique operational demands, underscores their importance in efficient materials handling. Industry experts must keenly assess their needs, consult trusted authorities, and consider future-proof solutions to maintain optimal conveyor system performance. Through insightful decision-making founded on practical experiences and authoritative knowledge, selecting the right conveyor pulley type becomes a vital contribution to operational excellence and success.

Snub and bend pulleys, while not driving pulleys, assist in tensioning the belt and improving its wrap angle around the driving pulley. This ensures that the belt maintains adequate tension throughout operation, contributing to the system's overall efficiency and durability. When considering material choices, steel is often the material of choice for conveyor pulleys due to its high strength and durability. However, for corrosive or wet environments, stainless steel or other corrosion-resistant materials might be necessary to extend the lifespan of the pulley. For professionals seeking authoritative guidance on pulley selection, evaluating factors such as material handling characteristics, environmental conditions, and belt specifications is paramount. An incorrect choice can lead to premature wear, increased maintenance costs, and even system failures. Expert consultations and adhering to industry best practices can streamline this decision-making process. Evaluating the expertise and experience of manufacturers and suppliers also plays a critical role in this selection journey. Vendors with deep industry knowledge can provide tailored solutions and innovative products meeting specific operational needs, ultimately fostering trust and reliability in their offerings. In conclusion, understanding the various types of conveyor pulleys, each tailored to unique operational demands, underscores their importance in efficient materials handling. Industry experts must keenly assess their needs, consult trusted authorities, and consider future-proof solutions to maintain optimal conveyor system performance. Through insightful decision-making founded on practical experiences and authoritative knowledge, selecting the right conveyor pulley type becomes a vital contribution to operational excellence and success.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS