Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 15, 2025 05:31

Back to list

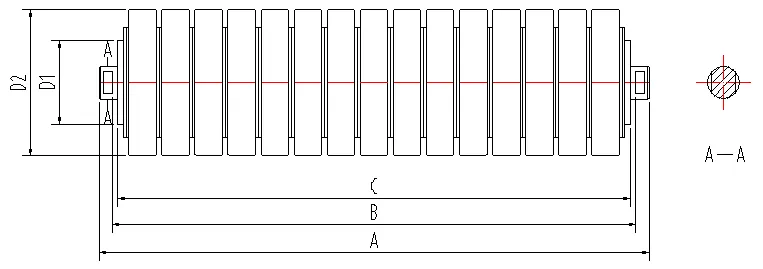

belt conveyor pulley

Conveyor belt pulleys play a critical role in the functioning of conveyor systems across diverse industries. These robust components not only facilitate the movement of materials but also significantly enhance operational efficiency. For businesses leveraging conveyor systems, understanding the nuances of conveyor belt pulleys is key to optimizing system performance. This comprehensive examination delves into the pivotal aspects of conveyor belt pulleys, emphasizing their utility, operational dynamics, and maintenance requirements.

Expertise in understanding the symptoms of pulley-related issues, such as unusual noise, vibration, or belt slippage, can prevent escalated failures. Addressing these symptoms promptly through realignment or part replacement not only preserves pulley function but also ensures continuous system operation. Moreover, technological advancements in condition monitoring tools have revolutionized pulley maintenance. Integrating sensors and IoT devices allows for continuous monitoring of pulley condition, predicting failures before they occur, and thus, reducing unexpected disruptions and maintenance costs. Businesses need authoritative insight when selecting conveyor belt pulleys. Partnering with reputable manufacturers who adhere to international standards and provide comprehensive support is crucial. These partnerships ensure access to high-quality, reliable pulleys and contribute to the consistent performance of conveyor systems, essential for meeting production targets and maintaining competitiveness. The use of high-precision conveyor belt pulleys contributes to the credibility and trustworthiness of a business's operational process. A conveyor system's reliability directly impacts product delivery schedules and overall customer satisfaction. As such, investing in quality pulleys is not merely a technical consideration but a strategic decision influencing the broader business operations. Conveyor belt pulleys are indispensable in achieving streamlined material movement and operational excellence. Their design, selection, and maintenance demand attention to detail and expert knowledge. By prioritizing these elements, businesses can ensure that their conveyor systems operate efficiently, minimizing downtime and maximizing productivity. Ultimately, the strategic integration of well-chosen pulleys into conveyor systems can yield significant improvements in material handling efficiency, bolstering both output and profitability.

Expertise in understanding the symptoms of pulley-related issues, such as unusual noise, vibration, or belt slippage, can prevent escalated failures. Addressing these symptoms promptly through realignment or part replacement not only preserves pulley function but also ensures continuous system operation. Moreover, technological advancements in condition monitoring tools have revolutionized pulley maintenance. Integrating sensors and IoT devices allows for continuous monitoring of pulley condition, predicting failures before they occur, and thus, reducing unexpected disruptions and maintenance costs. Businesses need authoritative insight when selecting conveyor belt pulleys. Partnering with reputable manufacturers who adhere to international standards and provide comprehensive support is crucial. These partnerships ensure access to high-quality, reliable pulleys and contribute to the consistent performance of conveyor systems, essential for meeting production targets and maintaining competitiveness. The use of high-precision conveyor belt pulleys contributes to the credibility and trustworthiness of a business's operational process. A conveyor system's reliability directly impacts product delivery schedules and overall customer satisfaction. As such, investing in quality pulleys is not merely a technical consideration but a strategic decision influencing the broader business operations. Conveyor belt pulleys are indispensable in achieving streamlined material movement and operational excellence. Their design, selection, and maintenance demand attention to detail and expert knowledge. By prioritizing these elements, businesses can ensure that their conveyor systems operate efficiently, minimizing downtime and maximizing productivity. Ultimately, the strategic integration of well-chosen pulleys into conveyor systems can yield significant improvements in material handling efficiency, bolstering both output and profitability.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS