Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt drive rollers

The Importance of Conveyor Belt Drive Rollers

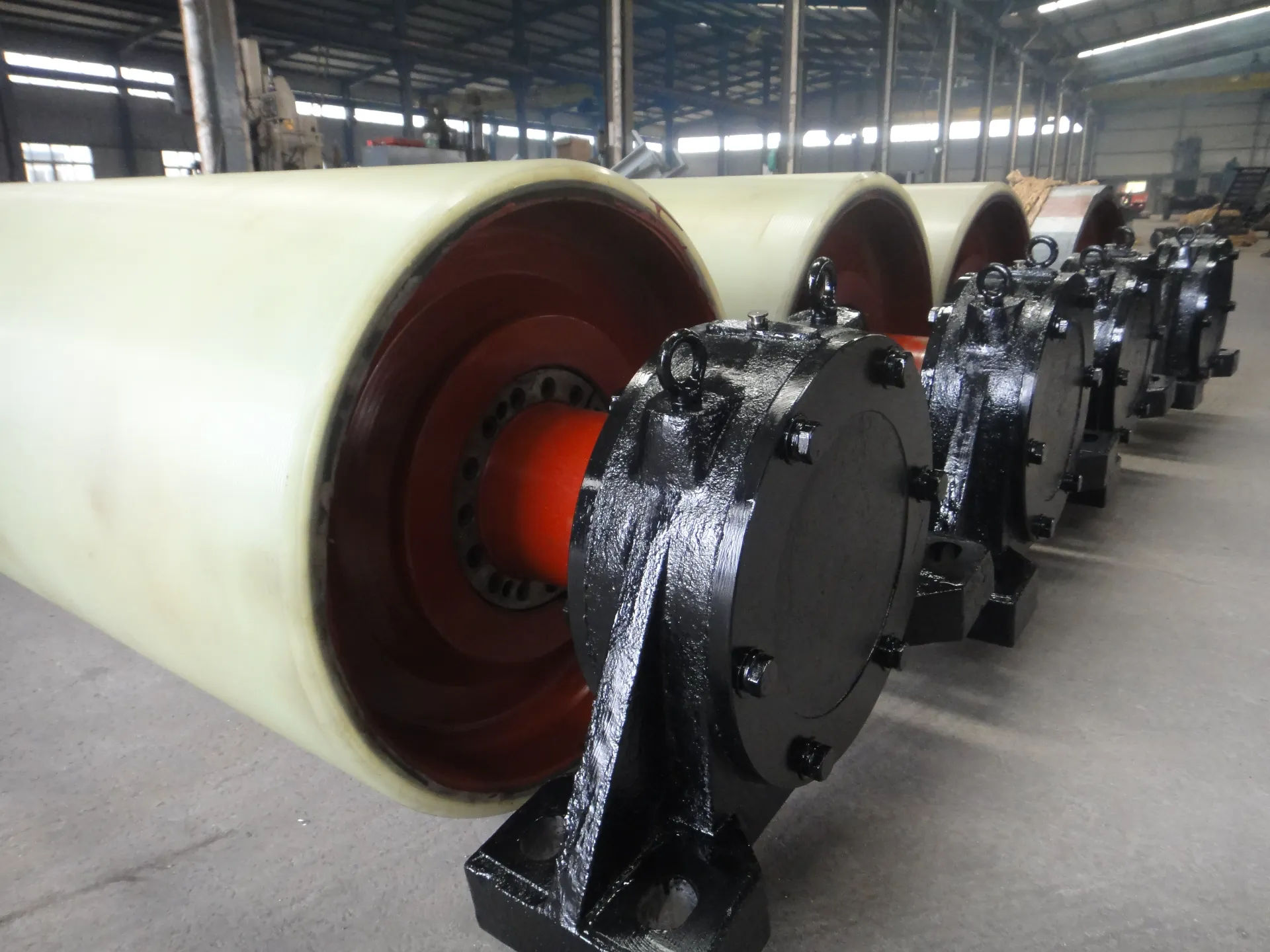

Conveyor belt systems have become an essential part of manufacturing and logistics industries around the world. They facilitate the smooth and efficient movement of goods, raw materials, and products within a facility. At the heart of every conveyor belt system lies the conveyor belt drive rollers, crucial components that ensure optimal functionality and performance.

Understanding Conveyor Belt Drive Rollers

Conveyor belt drive rollers, also referred to as drive pulleys, play a pivotal role in the operation of conveyor systems. These rollers are responsible for driving the conveyor belt, providing the necessary friction and torque to transport materials from one point to another. They are typically located at the head or discharge end of the conveyor system, and their performance significantly influences the efficiency of the entire operation.

Drive rollers come in various designs, sizes, and materials, each tailored to meet specific operational needs. They can be made from metal, plastic, or rubber, depending on the requirements of the application. The choice of material affects the roller's durability, weight, and friction characteristics, which are crucial for different transporting scenarios.

How Drive Rollers Function

The operation of drive rollers is relatively straightforward. When a motor powers the roller, it creates a rotational force that is transmitted to the conveyor belt. The friction between the roller surface and the belt allows for effective movement of materials along the conveyor system. The alignment of the rollers must also be precise to ensure that the belt travels smoothly without slipping or experiencing unnecessary wear and tear.

In addition, many modern conveyor systems incorporate advanced features such as variable speed drives

. This allows operators to adjust the speed of the conveyor belt according to the specific requirements of their operation, optimizing material handling and overall efficiency.conveyor belt drive rollers

Maintenance and Longevity of Drive Rollers

Like any mechanical component, drive rollers require regular maintenance to ensure their longevity and optimal performance. Over time, wear can occur due to friction and the weight of the materials being transported. Regular inspections are crucial for identifying signs of wear or damage, such as uneven surfaces or misalignments.

Lubrication is another critical aspect of maintenance. Keeping the bearings and roller surfaces well-lubricated helps reduce friction and heat, extending the lifespan of the rollers. Operators should also monitor the tension of the conveyor belt, as improper tension can lead to increased stress on the drive rollers and potentially cause failure.

Advancements in Conveyor Technology

The technology surrounding conveyor belt drive rollers has evolved significantly over the years. Innovations in materials science have led to the development of more durable and lightweight rollers, while advancements in motor technology have enhanced energy efficiency, reducing operational costs.

Some conveyor systems now utilize smart technology that allows for real-time monitoring of roller performance. This can include tracking parameters such as temperature, vibration, and rotational speed, all of which can help predict maintenance needs and prevent unexpected downtime.

Conclusion

In conclusion, conveyor belt drive rollers are vital components that ensure the effective operation of conveyor systems. Their design, maintenance, and the technology behind them play a significant role in the overall efficiency of material handling processes. As industries continue to pursue higher efficiency and lower operational costs, the importance of drive rollers will only continue to grow. It is essential for businesses to invest in high-quality materials and regular maintenance practices to optimize their conveyor systems and remain competitive in today’s fast-paced market.