Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor belt cleaner scraper

The Importance of Conveyor Belt Cleaner Scrapers

Conveyor belts are an essential component of many industrial operations, ensuring the efficient movement of materials and products from one point to another. However, over time, these belts can accumulate debris, dust, and other contaminants, leading to decreased efficiency and potential equipment damage. This is where conveyor belt cleaner scrapers come into play, offering a vital solution for maintaining the cleanliness and performance of conveyor systems.

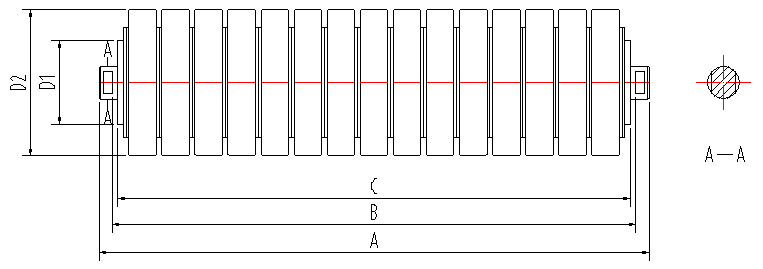

Conveyor belt cleaner scrapers are specialized tools designed to remove material build-up from the surface of a conveyor belt. They are typically mounted on the return side of the belt and work by scraping off any residual materials that cling to the belt as it moves. The removal of these materials is crucial for several reasons.

First and foremost, a clean conveyor belt operates more efficiently. When debris accumulates on the belt, it can lead to increased friction and resistance, causing the system to work harder. This not only results in higher energy consumption but also accelerates wear and tear on both the conveyor belt and the driving components. By effectively using conveyor belt cleaner scrapers, companies can ensure their systems run smoothly, leading to cost savings and increased productivity.

conveyor belt cleaner scraper

In addition to improving efficiency, conveyor belt scrapers play a significant role in maintaining product quality. Contaminants left on the belt can contaminate the product being transported, leading to quality issues and potentially affecting compliance with safety regulations. Industries such as food processing and pharmaceuticals, where hygiene standards are paramount, must use effective cleaning systems to prevent cross-contamination. Conveyor belt scrapers help in achieving the necessary cleanliness, thereby protecting product integrity and brand reputation.

Moreover, regular maintenance using conveyor belt scrapers can extend the lifespan of the conveyor system. When materials are allowed to build up on the belt, it can lead to misalignment and other mechanical problems. By incorporating scraper systems into routine maintenance practice, businesses can identify and address potential issues before they escalate into more significant problems, potentially reducing downtime and repair costs.

There are various types of conveyor belt cleaner scrapers available in the market, including mechanical and pneumatic options. Companies can choose scrapers based on their specific needs, the type of materials being transported, and the operating conditions of their conveyor systems. It is essential to select the right type of scraper to ensure optimal performance and longevity.

In conclusion, conveyor belt cleaner scrapers are critical for maintaining the efficiency and reliability of conveyor systems. They facilitate cleaner operations, enhance product quality, and prolong the life of conveyor belts and equipment. As industries continue to seek more efficient and cost-effective methods of operation, investing in proper belt cleaning solutions will remain a key component of operational success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025