Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 31, 2025 04:18

Back to list

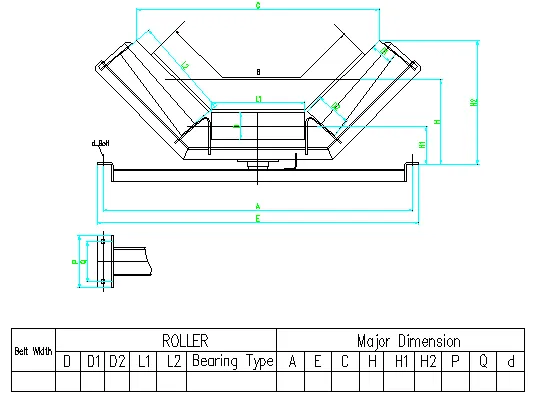

belt conveyor roller

Conveyor belt systems are pivotal in modern industrial setups, boosting efficiency and productivity. Among the integral components designed to maintain and optimize these systems are conveyor belt brush scrapers. Their design, functionality, and effectiveness have become crucial for industries that rely heavily on conveyor operations. Let's delve into a comprehensive exploration of these essential devices.

From an environmental standpoint, brush scrapers also present a sustainable solution by reducing material waste. By ensuring that all material is transferred properly along the conveyor system and that leftover material is redirected into the process stream, they help minimize waste. This ability to enhance material efficiency is particularly valuable in sectors aiming to improve their sustainability practices. The design and installation of brush scrapers must be precise to harness their full benefits. Meanwhile, the design must take into account specific industrial needs, including the type of material transported, the characteristics of the conveyor belt, and the ambient conditions of the working environment. Proper calibration is essential, as incorrect tension or positioning could lead to either inadequate cleaning or unnecessary wear on the belts. Expert installation and calibration are recommended to avoid such pitfalls and to ensure optimal performance. Trustworthiness and reliability in selecting a conveyor belt brush scraper supplier cannot be overstated. Partnering with suppliers who have established a reputation for quality and reliability in the market ensures that the products meet industry standards and requirements. Recommendations from industry experts and user testimonials provide valuable insights into the reliability and performance of these products, further guiding informed decision-making. Ultimately, the adoption of conveyor belt brush scrapers reflects a strategic approach in industrial operations, aiming for enhanced performance, cost efficiency, and sustainability. Their implementation signifies a commitment to operational excellence and is a testament to the evolving landscape of industrial maintenance technology. As these technologies advance, they continue to carry the potential to redefine productivity standards in multiple sectors.

From an environmental standpoint, brush scrapers also present a sustainable solution by reducing material waste. By ensuring that all material is transferred properly along the conveyor system and that leftover material is redirected into the process stream, they help minimize waste. This ability to enhance material efficiency is particularly valuable in sectors aiming to improve their sustainability practices. The design and installation of brush scrapers must be precise to harness their full benefits. Meanwhile, the design must take into account specific industrial needs, including the type of material transported, the characteristics of the conveyor belt, and the ambient conditions of the working environment. Proper calibration is essential, as incorrect tension or positioning could lead to either inadequate cleaning or unnecessary wear on the belts. Expert installation and calibration are recommended to avoid such pitfalls and to ensure optimal performance. Trustworthiness and reliability in selecting a conveyor belt brush scraper supplier cannot be overstated. Partnering with suppliers who have established a reputation for quality and reliability in the market ensures that the products meet industry standards and requirements. Recommendations from industry experts and user testimonials provide valuable insights into the reliability and performance of these products, further guiding informed decision-making. Ultimately, the adoption of conveyor belt brush scrapers reflects a strategic approach in industrial operations, aiming for enhanced performance, cost efficiency, and sustainability. Their implementation signifies a commitment to operational excellence and is a testament to the evolving landscape of industrial maintenance technology. As these technologies advance, they continue to carry the potential to redefine productivity standards in multiple sectors.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS