Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

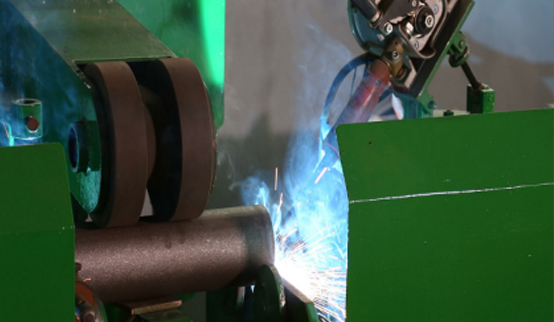

Zulu conveyor assembly

The Role and Evolution of Conveyor Assembly in Modern Manufacturing

Conveyor assembly systems are integral to contemporary manufacturing processes, serving as the backbone for efficient production lines in various industries. These systems enable the seamless movement of materials, components, and finished products, significantly enhancing productivity while minimizing labor costs. As industries evolve, conveyor assembly continues to adapt, incorporating advanced technologies and innovative designs that cater to the demands of modern production.

Historical Context

The concept of conveyor systems dates back to the late 18th century, but they significantly gained prominence during the early 20th century with the advent of the assembly line proposed by Henry Ford. This method revolutionized manufacturing, as it allowed for mass production of goods by streamlining workflow. Conveyors facilitated the movement of materials from one workstation to another, drastically reducing the time and effort required to assemble products. Over the decades, improvements in conveyor design and materials have led to the development of various systems tailored for specific applications, transforming the landscape of manufacturing.

Types of Conveyor Systems

Conveyor assembly systems come in multiple forms, each designed to cater to specific manufacturing needs

. The most common types include1. Belt Conveyors Often used for transporting bulk materials, belt conveyors employ a continuous loop of material to move items along the production line. They are versatile and can handle a wide range of products.

2. Roller Conveyors These systems utilize a series of rollers to transport items. They are particularly effective for handling heavier materials and are common in warehouses and distribution centers.

3. Chain Conveyors Ideal for heavy-duty applications, chain conveyors employ a chain mechanism to move products through the assembly process. They are commonly used in industries like automotive manufacturing.

4. Pneumatic Conveyors These conveyors use air pressure to transport lightweight materials through tubes. They are highly efficient for moving powders and granules in industries such as food processing and pharmaceuticals.

5. Automated Conveyor Systems With advancements in technology, automated conveyor systems incorporate robotics and sensors to enhance efficiency. These systems not only transport products but also assist in sorting and packaging, thereby reducing the need for manual intervention.

conveyor assembly

Advantages of Conveyor Assembly Systems

The integration of conveyor assembly systems within manufacturing processes offers numerous benefits

1. Increased Efficiency By automating the process of transporting materials, manufacturers can significantly reduce production time. This leads to higher output and improved delivery times.

2. Cost Reduction While the initial investment in conveyor systems can be substantial, the long-term savings in labor costs and increased productivity often outweigh the initial financial commitment.

3. Enhanced Safety Conveyor systems minimize manual handling, reducing the risk of workplace injuries. Additionally, automated systems can handle hazardous materials safely, protecting workers and ensuring compliance with safety regulations.

4. Flexibility Modern conveyor systems can be easily reconfigured or expanded to accommodate changes in production volume or product lines. This adaptability is crucial in today’s fast-paced market, where demands can shift rapidly.

Future Prospects

As technology continues to advance, the future of conveyor assembly systems looks promising. The integration of smart technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning is set to revolutionize the way conveyor systems operate. These technologies will enable real-time monitoring and predictive maintenance, minimizing downtime and enhancing overall efficiency.

Moreover, the push for sustainability and eco-friendly practices is leading manufacturers to develop energy-efficient conveyor systems, reducing their carbon footprint while maintaining productivity.

Conclusion

In summary, conveyor assembly systems play a crucial role in modern manufacturing, providing a framework for efficiency, safety, and cost-effectiveness. As industries continue to evolve, the adaptability and technological advancements within conveyor systems will ensure they remain a vital component of production processes. The future promises even greater innovations that will further streamline operations and elevate manufacturing standards globally.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025