Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor accessories

Conveyor Accessories Enhancing Efficiency and Safety in Material Handling

In today's fast-paced industrial environment, the efficiency of material handling systems is crucial for operational success. Among the pivotal components of these systems are conveyor accessories, which play an essential role in optimizing performance, ensuring safety, and extending equipment life. This article explores the various types of conveyor accessories, their functionalities, and the critical benefits they offer across different industries.

Types of Conveyor Accessories

Conveyor accessories encompass a wide range of components designed to enhance the performance of conveyor systems. Key accessories include

1. Conveyor Belts The most integral part of any conveyor system, conveyors come in various materials, including rubber, plastic, and metal. The choice of belt material significantly influences the system's efficiency and suitability for different applications.

2. Guides and Rails Conveyor guides and rails are employed to direct and stabilize materials on the conveyor. They prevent items from veering off track, ensuring smooth transport and reducing the risk of damage.

3. Chutes and Hoppers Chutes facilitate the transitions between different conveyor systems or between a conveyor and a storage area. Hoppers provide a buffer storage space that helps manage fluctuations in material flow.

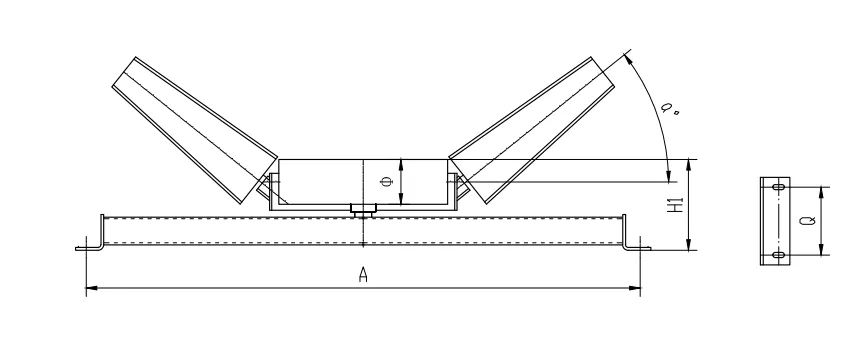

4. Rollers and Idlers Rollers and idlers support the conveyor belt and reduce friction, facilitating smoother movement of materials. They come in various designs, including tapered, flat, or rubber-coated, tailored for specific operational needs.

5. Transfer Plates and Applicators These accessories aid the movement of products between adjacent systems or stages in a production line. They ensure seamless transitions, minimizing the risk of spills or downtime.

6. Safety Guards and Stop Switches Safety is paramount in any industrial setting. Conveyor safety guards prevent accidental contact with moving parts, while stop switches allow for immediate halting of the system in emergencies, protecting both personnel and equipment.

conveyor accessories

Benefits of Conveyor Accessories

The incorporation of appropriate conveyor accessories into material handling systems provides multiple advantages

1. Improved Efficiency Accessories like rollers and guides ensure that materials flow smoothly, minimizing delays and bottlenecks in production processes. As a result, companies can achieve higher throughput and more efficient use of resources.

2. Increased Safety Safety features integrated into conveyor systems, such as guards and stop switches, help prevent workplace accidents. By reducing risks, businesses can foster a safer environment, ensuring compliance with health and safety regulations.

3. Enhanced Reliability The right accessories can help minimize wear and tear on the conveyor system, improving its longevity. Improved reliability means less downtime and reduced maintenance costs, ultimately leading to significant savings.

4. Flexibility Various conveyor accessories enable industries to customize their material handling systems according to specific requirements. This flexibility helps businesses adapt to changing operational needs, whether that involves scaling up production or accommodating different types of products.

5. Ergonomics and Accessibility Certain accessories are designed to enhance the ergonomic aspects of material handling, making it easier for employees to load and unload products. This not only boosts productivity but also contributes to worker satisfaction and morale.

Conclusion

Investing in quality conveyor accessories is pivotal for any business that relies on material handling systems. By enhancing efficiency, improving safety, and increasing the overall reliability of operations, these accessories contribute to the smooth functioning of industrial processes. As industries continue to evolve, the demand for tailored conveyor solutions and innovative accessories will likely rise, emphasizing the importance of staying updated with the latest advancements in conveyor technology. Whether in manufacturing, distribution, or warehousing, the right conveyor accessories can make a significant difference in operational efficiency and safety, driving businesses toward greater success.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025