Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu conveyor accessories

The Importance of Conveyor Accessories in Modern Material Handling

In today's fast-paced industrial landscape, effective material handling is crucial for maintaining efficiency in production lines and logistics. At the heart of these systems lies the conveyor belt, a vital component for transporting materials within factories, warehouses, and distribution centers. However, to ensure these conveyor systems operate at peak performance, a range of conveyor accessories is needed. This article will explore the significance of conveyor accessories and their contribution to streamlined operations.

Understanding Conveyor Accessories

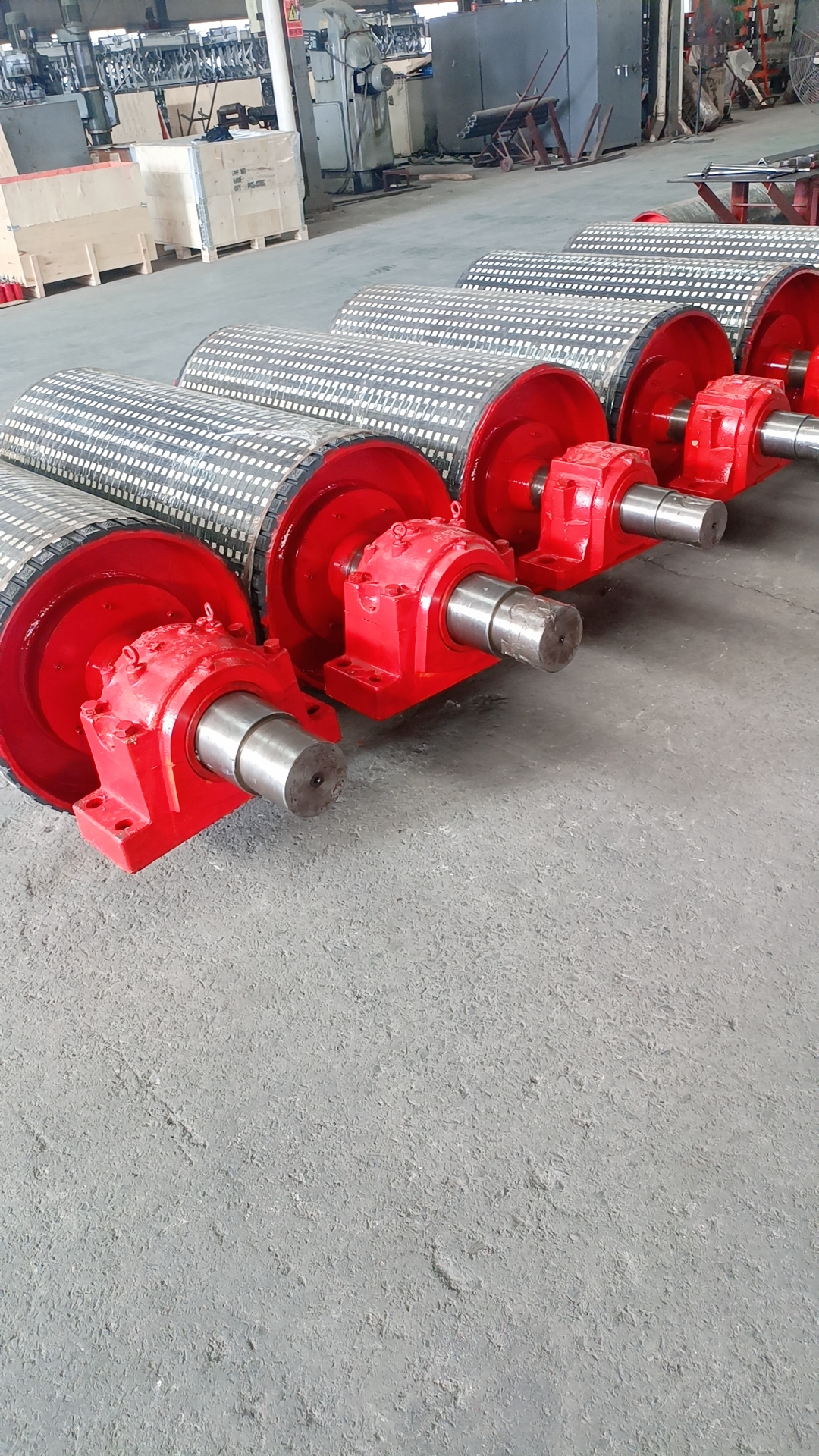

Conveyor accessories are auxiliary components that enhance the functionality and efficiency of conveyor systems. They can include items such as conveyor rollers, belts, pulleys, guards, and maintenance tools. While conveyors are designed to move materials efficiently, these accessories play a pivotal role in optimizing that movement, improving safety, and reducing downtime.

Types of Conveyor Accessories

1. Conveyor Rollers Rollers are one of the most common conveyor accessories and are essential for supporting the belt and the materials being transported. They come in various designs tailored for specific applications, including gravity rollers for low-speed transport and powered rollers for high-speed operations. The choice of roller can impact the efficiency and longevity of the entire conveyor system.

2. Conveyor Belts The type of conveyor belt used can greatly influence the performance of a conveyor system. Belts vary in material, thickness, and width to accommodate different loads and environmental conditions. Advanced belts may include features like slip-resistant surfaces, heat resistance, or specialized coatings to handle specific materials such as food products or chemicals.

3. Pulleys and Drives Pulleys are crucial for directing and supporting the conveyor belt and come in different types, including drive pulleys and snub pulleys. The drive pulley is responsible for the movement of the belt, while the snub pulley provides tension to ensure the belt remains securely in position. Properly configured pulleys help minimize wear and tear on the belt, enhancing its lifespan.

4. Guards and Safety Accessories Safety is paramount in any industrial setting. Guards are installed to protect workers from moving parts and prevent materials from escaping the system. Additional safety accessories may include emergency stop buttons, warning lights, and safety signage that alert workers to potential hazards.

conveyor accessories

5. Maintenance Tools and Accessories Regular maintenance is essential for ensuring the longevity and effectiveness of conveyor systems. Accessories such as belt cleaners, lubricants, and tensioning devices are vital for keeping the system running smoothly. Regular maintenance can prevent breakdowns and costly downtime, ensuring that production schedules are met.

The Benefits of Using Conveyor Accessories

1. Enhanced Efficiency Conveyor accessories streamline the movement of materials, reducing delays and increasing throughput. Properly maintained and equipped systems can handle larger volumes while maintaining speed and reliability.

2. Improved Safety Incorporating safety accessories protects workers and minimizes the risk of accidents. Ensuring that safety guards and emergency devices are in place contributes to a safer working environment.

3. Reduced Downtime Utilizing effective maintenance tools and accessories leads to fewer breakdowns and disruptions. This not only saves costs in repairs but also enhances productivity by ensuring that operations can run continuously.

4. Customization The wide array of available conveyor accessories allows for custom solutions tailored to specific operational needs. Whether adapting to unique product shapes or environmental challenges, the right accessories can optimize conveyor performance.

Conclusion

In summary, conveyor accessories are indispensable in modern material handling systems. They enhance the efficiency, safety, and durability of conveyor systems while helping businesses maintain competitive advantages. As industries continue to evolve, the importance of these accessories will only grow, highlighting the need for investment in quality components and regular maintenance. By understanding and utilizing conveyor accessories effectively, companies can ensure their material handling processes are as efficient and safe as possible. By prioritizing these components, businesses can stay ahead in an increasingly demanding industrial environment.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025