Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Conveyor Take Up Pulley - Optimize Your Conveyor Belt System

Conveyor Take-Up Pulley An Essential Component in Material Handling Systems

In the field of material handling, the conveyance of goods and products relies heavily on an array of components, among which the conveyor take-up pulley plays a crucial role. This essential element aids in maintaining the tension of the conveyor belt, ensuring efficient operation and longevity of the entire system.

Understanding the Take-Up Pulley

A conveyor take-up pulley is typically positioned at the end or at an intermediate section of a conveyor belt system. Its primary function is to adjust the tension of the belt. Proper belt tension is vital as it prevents slippage during operation, ensures that materials are transported efficiently, and minimizes wear and tear on both the belt and the components connected to it. Without adequate tension, a conveyor belt may sag, leading to misalignment, reduced operational efficiency, and increased maintenance costs.

Types of Take-Up Systems

There are several types of take-up systems that can be utilized depending on the specific needs of a conveyor system

1. Gravity Take-Up This is the most common type, where the pulley is suspended and the weight of the take-up pulley and additional weights provide the necessary tension. The simplicity of this system makes it a popular choice for many industrial applications.

2. Automatic Take-Up In this system, a tensioning device automatically adjusts the position of the pulley to maintain consistent belt tension. This method is beneficial in high-speed applications or in systems where fluctuating loads may cause changes in tension.

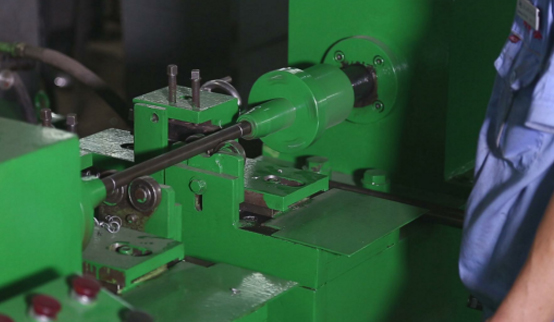

conveyor take up pulley

3. Manual Take-Up Some systems may require manual adjustments to the take-up pulley. While this can be effective, it necessitates regular checks and maintenance to ensure optimal tension is achieved.

Importance of Proper Maintenance

Regardless of the type of take-up pulley in use, regular maintenance is critical. Dirt, debris, and wear can accumulate on the pulley and its associated components, leading to decreased performance. Regular inspections and timely replacement of worn parts can prevent operational downtime and extend the lifespan of the conveyor system.

Advancements in Technology

The development of smart technologies has also begun to impact the functioning of conveyor take-up systems. Sensors can now monitor tension levels in real-time, providing valuable data that can lead to proactive maintenance interventions. This technological evolution not only enhances operational efficiency but also supports predictive maintenance strategies, thereby reducing unplanned outages.

Conclusion

In summary, the conveyor take-up pulley plays an indispensable role in the operational integrity of conveyor systems. By maintaining appropriate belt tension, it contributes to the efficiency, safety, and longevity of material handling operations. As industries continue to evolve, staying updated with advancements in technology and maintenance practices will allow operators to maximize the performance of their conveyor systems, paving the way for increased productivity and cost-effectiveness in material handling processes. The significance of this component, therefore, cannot be overstated—it is indeed a linchpin in the successful operation of conveyor systems.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025