Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Conveyor Belt Idler Design - Optimizing Efficiency and Performance

Conveyor Belt Idler Design An Overview

Conveyor belts are pivotal in the transportation of materials across various industries, from mining to manufacturing. Central to their operation is the idler, a crucial component that minimizes belt friction, supports the load, and contributes to the overall efficiency of the conveyor system. In this article, we discuss the fundamental principles behind the design of conveyor belt idlers, their types, and the factors influencing their performance.

Understanding Conveyor Belt Idlers

Idlers are essentially rollers that support the conveyor belt and its load, ensuring smooth operation. They are designed to carry the weight of the belt and the materials being transported without causing excessive wear. This component is vital for maintaining belt tension and alignment, which prevents slippage and misalignment that could lead to operational failures.

Types of Idlers

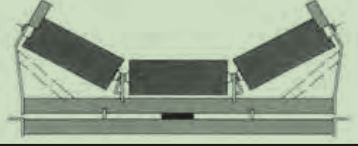

The design of idlers may vary based on the specific requirements of the conveyor system. The primary types include

1. Carrier Idlers These are the most common type, designed to support the belt and the load. They come in various shapes and sizes, often featuring a slight incline to enhance material flow.

2. Return Idlers Located on the return side of the conveyor, these idlers support the empty belt as it returns to the loading area. They typically have a flatter design to minimize the risk of material falling off.

3. Impact Idlers Positioned at loading points, impact idlers are designed to absorb the energy from falling materials, reducing the wear on the belt and other components. They often feature reinforced structures to withstand heavy loads.

conveyor belt idler design

4. Training Idlers These are used to keep the belt on track. They are equipped with automatic adjustment systems that help in realigning the conveyor belt if it begins to drift.

Key Considerations in Idler Design

When designing conveyor belt idlers, several factors must be considered to ensure optimal performance

- Load Capacity Idlers must be designed to support the anticipated load and operate under varying conditions. The material used in their construction is critical, often requiring materials that combine strength with lightweight properties.

- Environmental Factors Idler design should accommodate the environmental conditions in which they will operate. This includes factors such as temperature ranges, exposure to chemicals, and potential for corrosion.

- Maintenance Effective idler design allows for easy maintenance and replacement. This can include features such as lubricated bearings and quick-release mechanisms, reducing downtime during operations.

- Energy Efficiency The design should minimize friction and wear. Using advanced materials and engineering techniques can lead to lower energy consumption and improved efficiency.

Conclusion

The design of conveyor belt idlers is a crucial aspect of conveyor system functionality. A well-designed idler can lead to increased efficiency, reduced operational costs, and prolonged equipment lifespan. By understanding the types of idlers available and the factors influencing their design, industries can ensure that their conveyor systems operate smoothly and effectively, catering to their specific material handling needs. As technology advances, innovations in idler design will further enhance the performance and reliability of conveyor systems, making them an indispensable part of modern industrial operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025