Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 24, 2025 05:57

Back to list

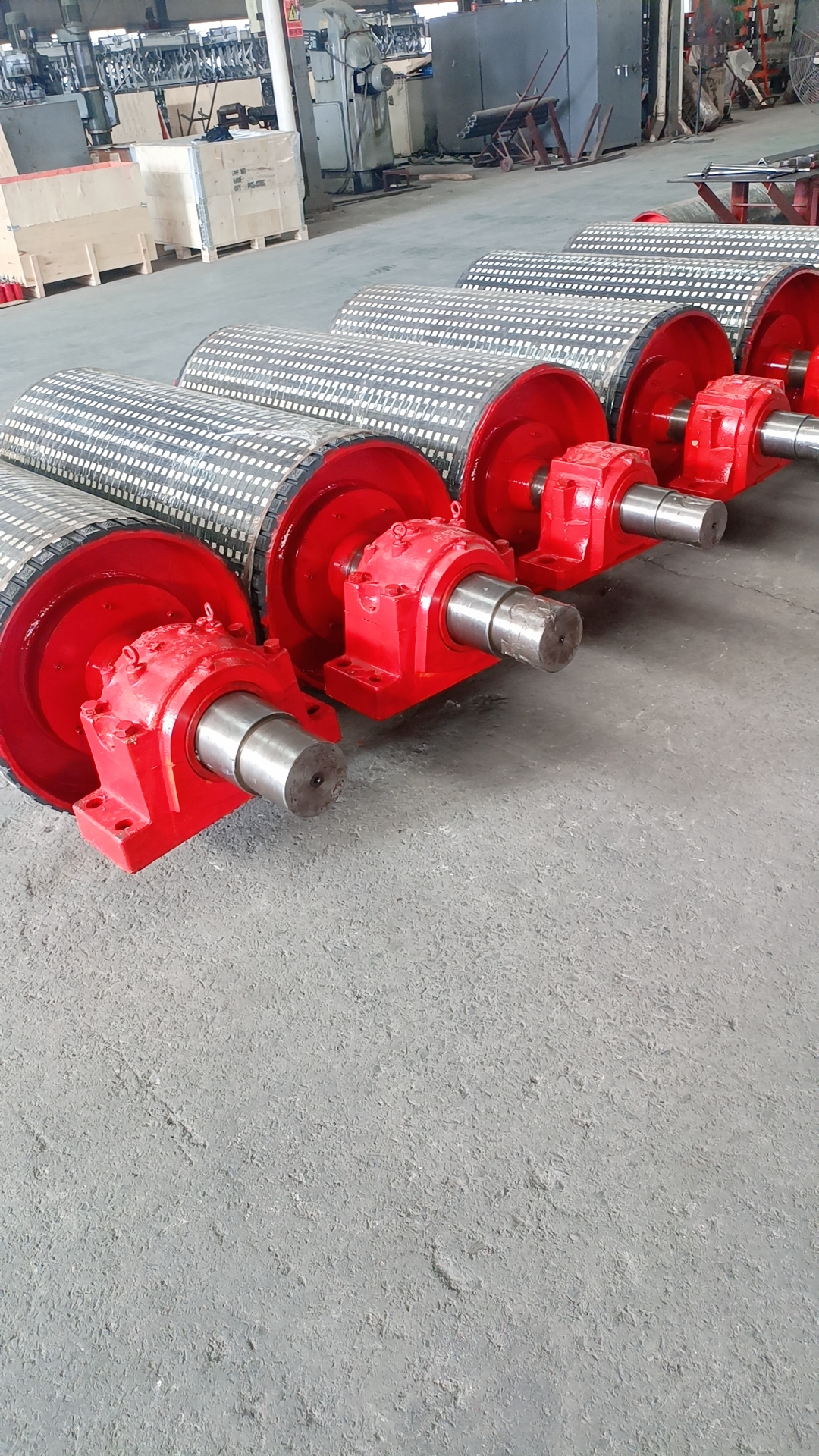

Taper Roller

Navigating the selection of a cone roller, especially for industrial applications, can be a complex task. Understanding the nuances of this seemingly simple component can significantly impact machine efficiency and overall operational success. Here, we delve into cone rollers' crucial aspects with insights that meet the Experience, Expertise, Authoritativeness, and Trustworthiness criteria.

Moreover, these industry authorities provide comprehensive guides and training programs, empowering businesses to better integrate and maintain cone rollers. The collective expertise from these sources forms a foundation of best practices that other manufacturers and end-users can emulate. Trustworthiness Ensuring Quality and Performance The reliability of cone rollers is pivotal in daily operations. Trustworthy products come from manufacturers who adhere to stringent quality standards, such as ISO certifications. These standards ensure that each roller meets specific performance metrics, thereby guaranteeing durability and efficiency. Real-world case studies further testify to the reliability of high-quality cone rollers. For example, a logistics company reported a significant reduction in operational costs after switching to a premium provider, highlighting the long-term cost benefits derived from investing in trusted products. Furthermore, customer testimonials and independent reviews often serve as reliable indicators of a product's trustworthiness. Businesses should consider this feedback when selecting cone rollers, as they offer unfiltered insights into product performance and customer satisfaction. Conclusion In the dynamic landscape of industrial machinery, the choice of cone rollers can make or break a system's productivity and reliability. By factoring in material composition, design precision, and adherence to industry standards, businesses can ensure they select a product that aligns with their operational needs. Leveraging knowledge from industry leaders and real-world applications, companies can navigate the complexities of cone rollers with confidence, paving the way for enhanced efficiency and growth in their operations. When integrating cone rollers into your systems, consider these insights and prioritize quality and compatibility to harness these small components' significant potential.

Moreover, these industry authorities provide comprehensive guides and training programs, empowering businesses to better integrate and maintain cone rollers. The collective expertise from these sources forms a foundation of best practices that other manufacturers and end-users can emulate. Trustworthiness Ensuring Quality and Performance The reliability of cone rollers is pivotal in daily operations. Trustworthy products come from manufacturers who adhere to stringent quality standards, such as ISO certifications. These standards ensure that each roller meets specific performance metrics, thereby guaranteeing durability and efficiency. Real-world case studies further testify to the reliability of high-quality cone rollers. For example, a logistics company reported a significant reduction in operational costs after switching to a premium provider, highlighting the long-term cost benefits derived from investing in trusted products. Furthermore, customer testimonials and independent reviews often serve as reliable indicators of a product's trustworthiness. Businesses should consider this feedback when selecting cone rollers, as they offer unfiltered insights into product performance and customer satisfaction. Conclusion In the dynamic landscape of industrial machinery, the choice of cone rollers can make or break a system's productivity and reliability. By factoring in material composition, design precision, and adherence to industry standards, businesses can ensure they select a product that aligns with their operational needs. Leveraging knowledge from industry leaders and real-world applications, companies can navigate the complexities of cone rollers with confidence, paving the way for enhanced efficiency and growth in their operations. When integrating cone rollers into your systems, consider these insights and prioritize quality and compatibility to harness these small components' significant potential.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS