Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu concave guide roller

Understanding Concave Guide Rollers Functionality, Applications, and Benefits

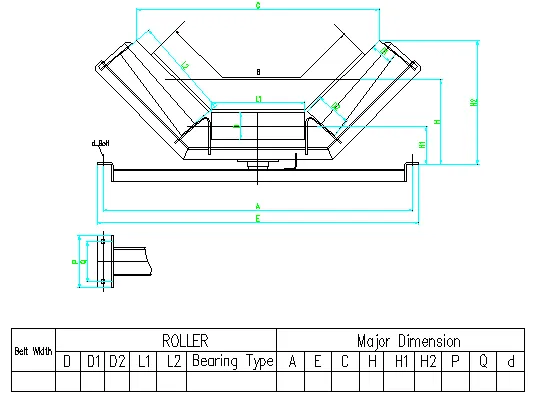

Concave guide rollers are crucial components in various industrial applications where smooth material handling and motion guidance are essential. These rollers are designed with a concave shape, allowing them to securely hold and guide materials such as belts, cables, or sheets during their movement. This article will delve into the functionality, applications, and benefits of concave guide rollers, highlighting their significance in today's manufacturing and processing industries.

Functionality of Concave Guide Rollers

The primary function of concave guide rollers is to maintain the alignment and positioning of moving materials. The concave design enables these rollers to cradle the material securely, preventing it from slipping off or misaligning during transportation. By ensuring that the material is held firmly in place, concave guide rollers reduce the risk of damage and enhance the overall efficiency of the conveying system.

In addition to alignment, concave guide rollers help in managing tension and load distribution. In scenarios where heavy materials are being transported, these rollers can mitigate the stress on the materials and the machinery involved. This reduces wear and tear on both the materials and the equipment, leading to longer service life and reduced maintenance costs.

Concave guide rollers are often constructed from durable materials such as steel, plastic, or rubber, depending on the specific application requirements. The choice of material affects the roller’s performance concerning load capacity, friction, and wear resistance, making it essential for engineers to select the appropriate type for their operational needs.

Applications of Concave Guide Rollers

Concave guide rollers find extensive use across various industries. Some common applications include

1. Conveyor Systems In manufacturing and warehouse environments, conveyor systems play a vital role in transporting goods. Concave guide rollers are used to maintain the alignment of conveyor belts, ensuring smooth and efficient movement of products.

2. Printing and Packaging Machines In the printing industry, concave guide rollers help guide paper through printers and packaging machines. They ensure that the paper remains aligned, preventing misprints and ensuring high-quality outputs.

concave guide roller

4. Metal Processing In metallurgy and metalworking, these rollers help guide sheets or long materials through various processing stages, such as cutting or bending, allowing for precision and ease of handling.

5. Construction and Heavy Machinery In the construction sector, concave guide rollers are used to manage cables and belts in heavy machinery, providing a safe and reliable way to transfer power and materials.

Benefits of Concave Guide Rollers

The use of concave guide rollers in industrial applications offers several advantages

1. Improved Material Handling The secure grip provided by concave rollers minimizes the chances of material shifting or falling off, leading to increased safety and reduced product loss.

2. Enhanced Operational Efficiency By maintaining the proper alignment and tension of materials, concave guide rollers contribute to smoother operations, reducing downtime caused by misalignment or jams.

3. Lower Maintenance Costs With reduced wear and tear on both the materials and machinery, companies can expect lower maintenance costs and longer intervals between servicing.

4. Versatility Concave guide rollers can be customized in terms of size and material, making them suitable for a wide range of applications across different industries.

5. Cost-Effectiveness Although the initial investment might be significant, the long-term benefits and savings generated through improved efficiency and reduced maintenance make concave guide rollers a cost-effective choice.

Conclusion

In conclusion, concave guide rollers are indispensable components in modern industrial processes. Their ability to ensure material alignment, manage tension, and provide operational efficiency makes them essential in a variety of applications. With the ever-increasing demand for optimized production processes, the role of concave guide rollers will continue to grow, underscoring their importance in the landscape of manufacturing and material handling. Investing in high-quality concave guide rollers can lead to significant operational benefits, making them a worthwhile consideration for any industrial setup.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025