Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

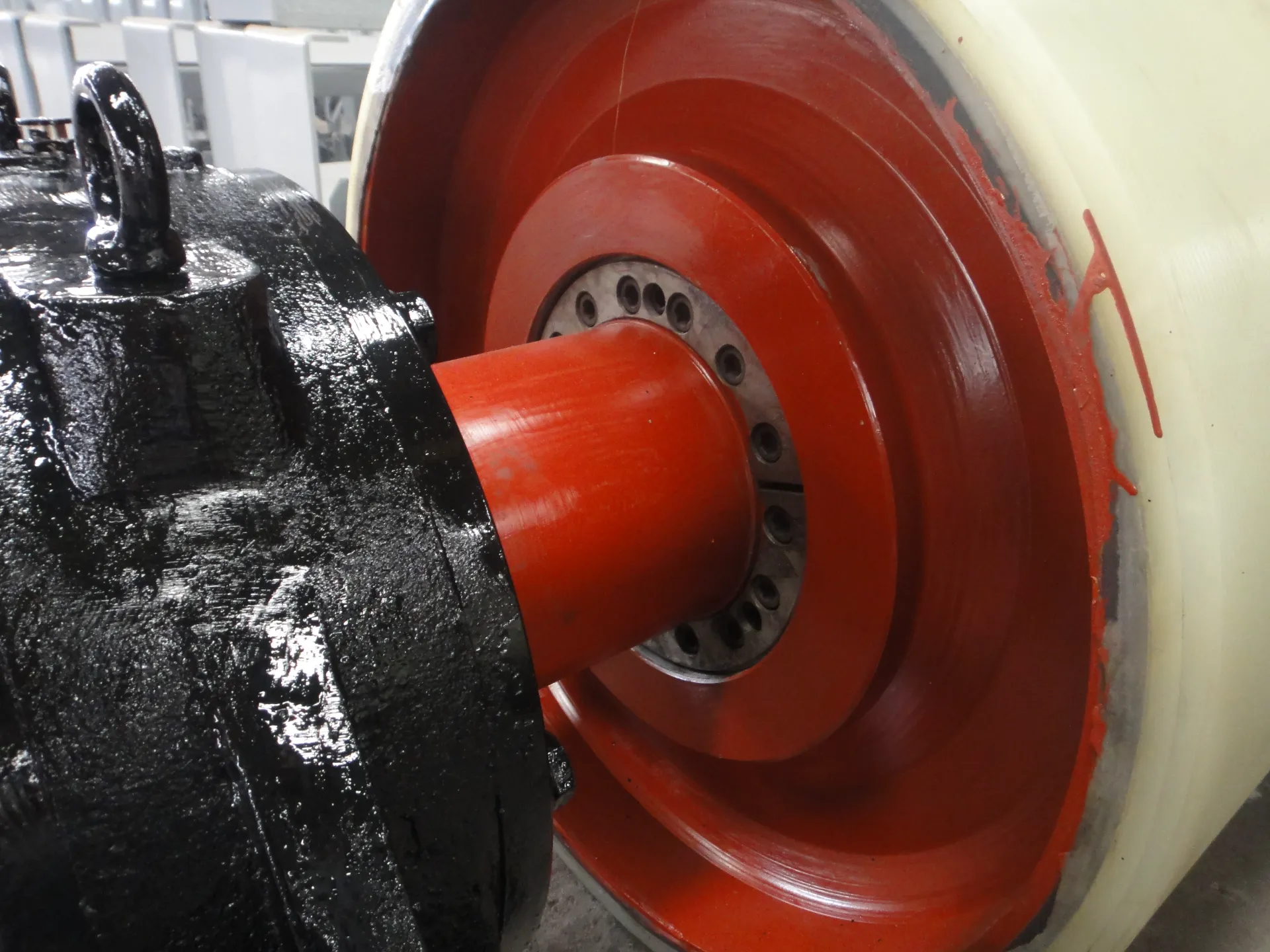

Zulu concave guide roller

Understanding Concave Guide Rollers An Essential Component in Machinery

Concave guide rollers play a crucial role in the machinery and manufacturing sectors, serving as key components that help ensure the smooth operation of various systems. These specialized rollers are designed to guide, support, and direct the movement of materials, particularly in conveyor systems and automated production lines. Their unique concave shape allows for optimal alignment of materials, reducing wear and tear while improving overall efficiency.

Design and Functionality

The distinct curvature of concave guide rollers allows them to effectively cradle the materials they are guiding, which is especially beneficial for handling irregularly shaped items. This design minimizes the risk of misalignment, which can lead to costly downtime in production processes. By maintaining the correct path, these rollers help prevent material jam-ups and enhance the reliability of the entire system.

Manufacturers often utilize various materials when designing concave guide rollers. Common materials include steel for strength, rubber for flexibility, and plastic for lightweight applications. The choice of material largely depends on the specific requirements of the application, including the load capacity, speed, and environmental conditions. For instance, rubberized rollers are ideal for applications that require a strong grip and reduced noise, while metal rollers are preferred for heavy-duty scenarios where durability is paramount.

Applications in Various Industries

concave guide roller

Concave guide rollers are versatile components used across a range of industries, including manufacturing, packaging, and logistics. In conveyor systems, they help align products as they move along the belt, ensuring consistent and efficient transport. In packaging, these rollers assist in guiding materials through various stages of production, from filling to sealing. Their reliable performance can significantly improve throughput and reduce waste, making them an invaluable asset in modern manufacturing processes.

In addition to these applications, concave guide rollers are also found in the transportation sector, especially in rail systems, where they help guide trains along tracks. Their design allows for smooth transitions, ensuring safety and reliability in transport.

Maintenance and Longevity

To ensure the longevity and efficiency of concave guide rollers, regular maintenance is essential. This includes inspecting the rollers for wear and tear, cleaning them to prevent buildup of debris, and lubricating moving parts to reduce friction. By implementing a consistent maintenance schedule, businesses can maximize the lifespan of their equipment, leading to significant cost savings over time.

In conclusion, concave guide rollers are indispensable components in various machinery systems, providing stability and direction for materials and products. Their unique design and adaptability to different industries make them a valuable investment for businesses looking to enhance their production efficiency. As technology continues to evolve, the development of advanced materials and designs for concave guide rollers will undoubtedly further improve their functionality and application range, paving the way for more efficient manufacturing processes in the future.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025