Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu chevron wing pulley

The Chevron Wing Pulley An Essential Component in Conveyor Systems

In the realm of materials handling, the choice of components is paramount to the efficiency and effectiveness of conveyor systems. One such component that has gained significant attention in recent years is the chevron wing pulley. This specialized type of pulley has become increasingly popular due to its distinctive design and the myriad benefits it offers in various industrial applications.

Understanding the Design of Chevron Wing Pulleys

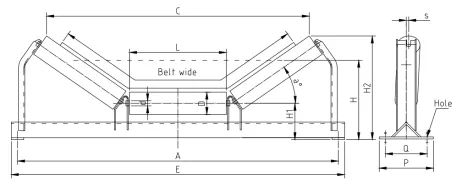

Chevron wing pulleys are characterized by their unique wing-like structures that protrude from the pulley body. This design serves a critical function it enhances the performance of conveyor belts by helping to prevent material spillage, improve belt tracking, and reduce slippage. The chevron pattern allows for better engagement with the conveyor belt, ensuring that materials are transported efficiently from one point to another.

Typically made from durable materials such as steel or polymer, chevron wing pulleys are engineered to withstand harsh industrial environments. Their robust design means they can handle heavy loads and withstand the wear and tear of continuous operation. This resilience makes them ideal for sectors such as mining, agriculture, and manufacturing, where heavy materials need to be transported over long distances.

Advantages of Using Chevron Wing Pulleys

1. Improved Material Handling One of the primary advantages of chevron wing pulleys is their ability to minimize spillage. Traditional pulleys can lead to considerable loss of materials if they are not designed with effective containment features. The chevron design, with its raised wings, helps to keep materials securely on the belt, reducing waste and increasing efficiency.

chevron wing pulley

2. Enhanced Belt Tracking The unique shape of chevron wing pulleys plays a vital role in belt tracking. Misalignment during operation can lead to significant issues, including increased wear on the belt and the potential for accidents. Chevron wing pulleys maintain better control over the belt, ensuring smooth operation and prolonging the life of the conveyor system.

3. Reduced Slippage Slippage occurs when the belt fails to effectively transfer power to the materials being conveyed. Chevron wing pulleys enhance friction between the pulley and the belt, significantly reducing slippage and facilitating smoother operations. This improved engagement also helps in maintaining consistent speeds, ultimately enhancing productivity.

4. Versatility Chevron wing pulleys are highly versatile and can be adapted for various conveyor systems and configurations. Whether in inclined systems where material movement is vertical or horizontal applications, these pulleys can be optimized to meet specific operational needs. This versatility makes them a preferred choice across industries.

5. Cost-Effective Solution While the initial investment in chevron wing pulleys may be higher than traditional pulleys, the long-term benefits outweigh the costs. The reduced material spillage, lower maintenance needs, and extended lifespan of the conveyor system all contribute to significant savings over time, making chevron wing pulleys a financially wise investment.

Conclusion

In conclusion, the chevron wing pulley has emerged as a vital component in modern conveyor systems. Its unique design and numerous advantages significantly enhance the performance and reliability of material handling operations. By minimizing spillage, improving belt tracking, and reducing slippage, these pulleys contribute to greater operational efficiency and cost savings. As industries continue to seek ways to optimize their processes, the chevron wing pulley stands out as a key player in advancing conveyor technology and improving productivity across various sectors.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025