Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 15, 2025 02:00

Back to list

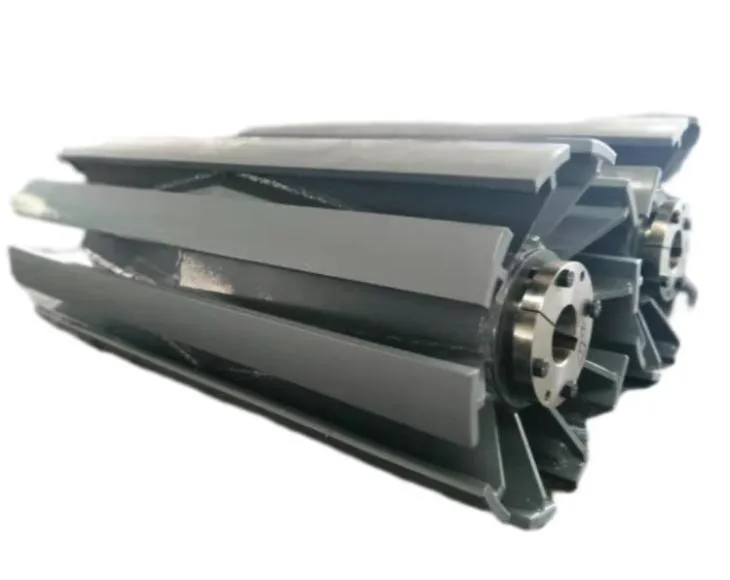

ceramic pulley lagging

Ceramic pulley lagging is revolutionizing the way industries handle conveyor belt systems, offering unparalleled performance and durability. This advanced technology is increasingly becoming the choice for industries that demand efficiency and reliability in their operations. With years of field experience, I can confidently assert the benefits that ceramic pulley lagging brings to the table, especially in heavy-duty applications.

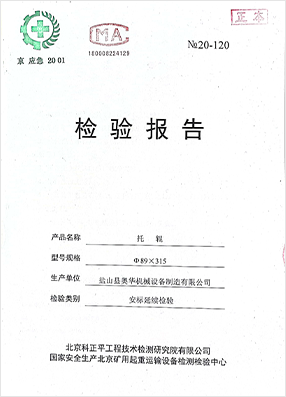

Furthermore, the authoritativeness of ceramic pulley lagging is reflected in its widespread adoption across various high-demand sectors. Leading manufacturers and plant operators endorse ceramic lagging as a standard solution for everyday challenges. The strategic selection of ceramic materials over conventional options is supported by extensive research and testing, highlighting ceramic lagging's superiority in efficiency and performance. Reliable data and case studies provide robust evidence of its capability to handle high-tension applications, assuring industry decision-makers of its resilient properties. Trustworthiness is a critical factor for any product, and ceramic pulley lagging doesn't fall short. Certified providers ensure that their lagging products meet the highest industry standards in quality and safety. This means that businesses investing in ceramic lagging can trust that they are opting for a solution that complies with rigorous quality controls and international standards. Additionally, with professional installation and regular inspections by trained personnel, ceramic pulley lagging maintains its performance throughout its operational life. In conclusion, ceramic pulley lagging is a game-changer for conveyor belt systems across a multitude of industries. The real-world experience and expertise demonstrate its undeniable advantages in wear resistance, traction, and reliability. Its authoritative status is validated through adoption by industry leaders, while its trustworthiness is assured by compliance with top-tier quality standards. Embracing ceramic pulley lagging means investing in a future of reduced operational costs, improved efficiency, and unparalleled reliability. It's the ultimate choice for industries committed to excellence in their field.

Furthermore, the authoritativeness of ceramic pulley lagging is reflected in its widespread adoption across various high-demand sectors. Leading manufacturers and plant operators endorse ceramic lagging as a standard solution for everyday challenges. The strategic selection of ceramic materials over conventional options is supported by extensive research and testing, highlighting ceramic lagging's superiority in efficiency and performance. Reliable data and case studies provide robust evidence of its capability to handle high-tension applications, assuring industry decision-makers of its resilient properties. Trustworthiness is a critical factor for any product, and ceramic pulley lagging doesn't fall short. Certified providers ensure that their lagging products meet the highest industry standards in quality and safety. This means that businesses investing in ceramic lagging can trust that they are opting for a solution that complies with rigorous quality controls and international standards. Additionally, with professional installation and regular inspections by trained personnel, ceramic pulley lagging maintains its performance throughout its operational life. In conclusion, ceramic pulley lagging is a game-changer for conveyor belt systems across a multitude of industries. The real-world experience and expertise demonstrate its undeniable advantages in wear resistance, traction, and reliability. Its authoritative status is validated through adoption by industry leaders, while its trustworthiness is assured by compliance with top-tier quality standards. Embracing ceramic pulley lagging means investing in a future of reduced operational costs, improved efficiency, and unparalleled reliability. It's the ultimate choice for industries committed to excellence in their field.

Next:

Latest news

-

Revolutionizing Conveyor Systems with Spiral Return RollersNewsMay.27,2025

-

Reliable Conveyor Pulley UpgradesNewsMay.27,2025

-

Optimizing Conveyor Efficiency with Roll Table Convey RollersNewsMay.27,2025

-

Maximizing Conveyor Efficiency with Wing PulleysNewsMay.27,2025

-

Maximize Conveyor Efficiency with Impact BedsNewsMay.27,2025

-

Clean Belt SolutionsNewsMay.27,2025

OUR PRODUCTS