Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 07, 2025 02:49

Back to list

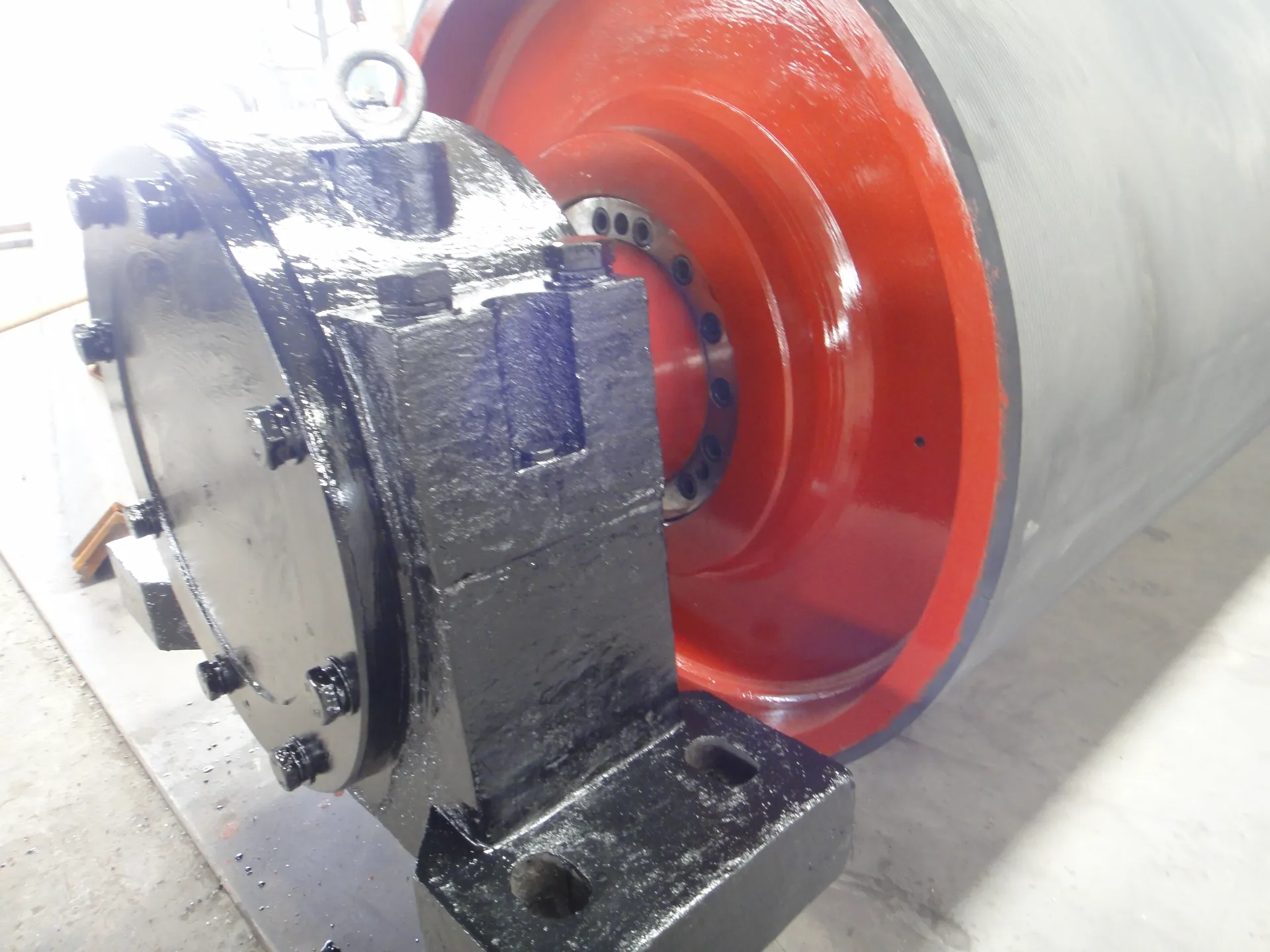

ceramic lagging pulley

Ceramic lagging pulleys represent a pivotal advancement in conveyor pulley technology, leveraging ceramic materials to offer superior performance and reliability in various industrial applications. These pulleys surpass the conventional steel or rubber-coated systems, offering unprecedented durability and efficiency. The science behind ceramic lagging revolves around the integration of ceramic tiles onto the pulley surface, which offers enhanced grip and wear resistance.

From an authority standpoint, several industry leaders have endorsed ceramic lagging technology. Renowned certification bodies have validated these products for use in rigorous environments, further driving their adoption across sectors. Manufacturers often provide comprehensive support, from installation guidance to troubleshooting assistance, affirming their commitment to quality and customer service. Trust in ceramic lagging pulleys is boosted by documented case studies reflecting their efficacy. Reports highlight marked improvements in operational efficiency and cost savings in diverse applications. End-users often share testimonials regarding the reduced energy consumption associated with smoother conveyor operations—proof of their impactful implementation. The sustainability benefits of ceramic lagging pulleys cannot be overlooked. Their durability translates into a reduced replacement rate, contributing to lower environmental impact through decreased manufacturing demands. Furthermore, the energy efficiency achieved by improved traction means these systems align with green initiatives, supporting organizations in their pursuit of reduced carbon footprints. In conclusion, ceramic lagging pulleys embody a strategic enhancement in conveyor technology, offering tangible benefits across industrial landscapes. Their durability, efficiency, and environmental advantages make them a top choice for modern operations seeking to optimize productivity and reliability. Embracing this technology not only fosters operational excellence but also positions businesses at the forefront of innovation and sustainability.

From an authority standpoint, several industry leaders have endorsed ceramic lagging technology. Renowned certification bodies have validated these products for use in rigorous environments, further driving their adoption across sectors. Manufacturers often provide comprehensive support, from installation guidance to troubleshooting assistance, affirming their commitment to quality and customer service. Trust in ceramic lagging pulleys is boosted by documented case studies reflecting their efficacy. Reports highlight marked improvements in operational efficiency and cost savings in diverse applications. End-users often share testimonials regarding the reduced energy consumption associated with smoother conveyor operations—proof of their impactful implementation. The sustainability benefits of ceramic lagging pulleys cannot be overlooked. Their durability translates into a reduced replacement rate, contributing to lower environmental impact through decreased manufacturing demands. Furthermore, the energy efficiency achieved by improved traction means these systems align with green initiatives, supporting organizations in their pursuit of reduced carbon footprints. In conclusion, ceramic lagging pulleys embody a strategic enhancement in conveyor technology, offering tangible benefits across industrial landscapes. Their durability, efficiency, and environmental advantages make them a top choice for modern operations seeking to optimize productivity and reliability. Embracing this technology not only fosters operational excellence but also positions businesses at the forefront of innovation and sustainability.

Next:

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS