Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu ceramic lagging conveyor pulley

Ceramic Lagging Conveyor Pulleys Enhancing Performance and Durability

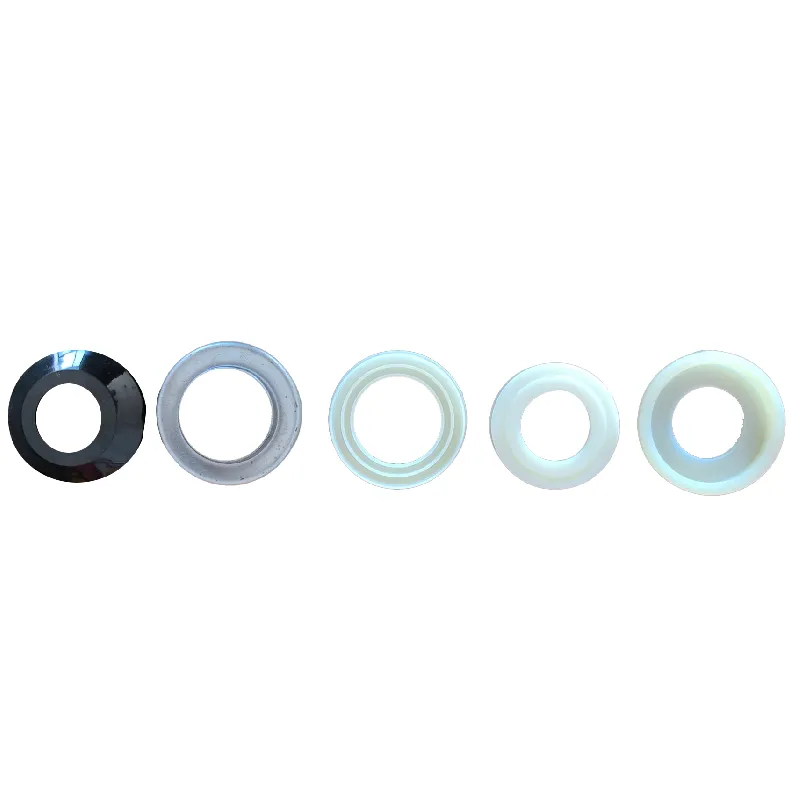

In today’s industrial landscape, conveyor systems are integral to the efficient transfer of materials. Among the components that significantly contribute to the effectiveness of these systems is the conveyor pulley. One innovative advancement in this area is the use of ceramic lagging on conveyor pulleys. This technology not only enhances performance but also extends the lifespan of the pulleys, making them a valuable asset for various industries.

Ceramic Lagging Conveyor Pulleys Enhancing Performance and Durability

One of the primary benefits of ceramic lagging is its ability to improve the overall efficiency of the conveyor system. The enhanced friction that ceramic lagging provides ensures that the conveyor belt maintains its grip, reducing slippage. This translates to a more consistent flow of materials and minimizes downtime due to maintenance and repairs. In industries like mining, where operational continuity is crucial, ceramic lagging can lead to improved productivity and reduced operational costs. Furthermore, the reduced slippage minimizes the energy required to transport materials, contributing to more sustainable operations.

ceramic lagging conveyor pulley

Durability is another significant advantage of ceramic lagging. The rugged nature of the ceramic materials used in the lagging process ensures that the pulleys can withstand harsh conditions, including extreme temperatures, moisture, and heavy loads. This durability means fewer replacements and repairs, resulting in lower long-term operational costs. Additionally, ceramic lagging can help mitigate the effects of corrosion, which is a common issue in many industrial settings.

Moreover, the installation of ceramic lagging can be done with relative ease. Existing pulleys can often be retrofitted with ceramic lagging without the need for complete replacement. This adaptability not only saves time and resources but also offers a cost-effective solution for companies looking to update their conveyor systems without incurring the full expense of new equipment.

The benefits of ceramic lagging extend beyond mere performance improvements. By enhancing pulley life and reducing maintenance needs, companies can allocate resources more effectively, focusing on core operations rather than constant repairs. This is particularly relevant in competitive industries where efficiency can significantly impact profitability.

In conclusion, ceramic lagging for conveyor pulleys emerges as a smart investment for industries reliant on conveyor systems. Its capacity to enhance traction, durability, and longevity not only boosts operational efficiency but also reduces long-term costs. As industries continue to look for ways to optimize performance and minimize downtime, the adoption of ceramic lagging technology is likely to grow, solidifying its place as a critical component in modern conveyor systems. Investing in ceramic lagging is not just a technical upgrade; it’s a strategic move toward achieving sustainable and efficient operations.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025