Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

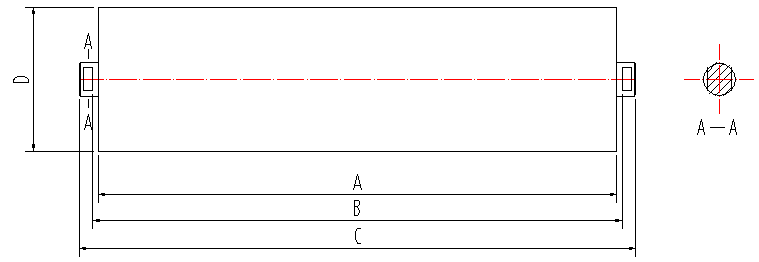

Zulu centre roller

The Evolution and Importance of Centre Roller Technology

In the realm of engineering and manufacturing, the centre roller plays a pivotal role across various applications, particularly in conveyor systems and material handling. This seemingly simple device, which functions as the central component of a roller system, is integral to enhancing efficiency, safety, and productivity in industrial operations. This article explores the evolution, functionality, and significance of centre rollers in modern technology.

Historical Context

The development of roller technology can be traced back to ancient civilizations, where rudimentary rollers were used to transport heavy objects over short distances. However, the innovation of the centre roller as we know it today emerged during the Industrial Revolution, when the demand for efficient transportation systems surged. The introduction of mechanized systems necessitated the need for reliable roller designs that could withstand heavy loads and facilitate smooth operations.

Design and Functionality

A centre roller typically consists of a cylindrical body mounted on a central axis, enabling it to rotate freely. This design allows for efficient movement of materials across various surfaces. The roller's central placement is crucial; it serves as the main point of rotation, distributing weight evenly and reducing the risk of wear and tear on the entire system.

The material composition of centre rollers has evolved significantly over the years. Initially, wooden rollers were common; however, advancements in materials science have led to the use of metals, plastics, and composites that offer increased durability and resistance to environmental factors. Modern centre rollers can be engineered to resist corrosion, abrasion, and varying temperature conditions, making them suitable for diverse industrial environments.

Application Across Industries

Centre rollers are ubiquitous in numerous sectors, including manufacturing, logistics, and agriculture

. In manufacturing, they are integral to conveyor systems that transport products from one stage of production to another. By minimizing friction and providing a smooth transition, centre rollers enhance the speed and efficiency of assembly lines.centre roller

In the logistics sector, the centre roller is a key component of automated sorting systems. These systems use centre rollers to move packages seamlessly through sorting facilities, ensuring quick and accurate distribution. The integration of smart technology in these systems has further improved efficiency by enabling real-time tracking and maintenance alerts, which helps prevent downtime.

Agricultural machinery also relies heavily on centre roller technology. In machines such as seeders and harvesters, centre rollers facilitate the movement of soil, seeds, or crops, ensuring optimal performance and output. The robustness of modern centre rollers is particularly beneficial in challenging outdoor environments, where they must withstand dust, moisture, and heavy loads.

Innovations and Future Trends

As industries continue to evolve, centre roller technology is expected to advance further. Innovations such as incorporating smart sensors into centre rollers can enhance their functionality by providing data on wear and performance. Predictive maintenance, enabled by such technology, can minimize unexpected failures and extend the lifespan of equipment.

Moreover, the increasing emphasis on sustainability has prompted manufacturers to explore eco-friendly materials for centre rollers. This shift not only reduces environmental impact but also aligns with global trends toward greener manufacturing practices.

Conclusion

The centre roller is a testament to how simple mechanical designs can have profound implications for efficiency in various industries. Its evolution from basic wooden constructs to sophisticated, durable components reflects the progress of engineering and technology. As industries continue to innovate and adapt to new challenges, the centre roller will undoubtedly remain a cornerstone of material handling systems, facilitating not just movement, but also a future of smarter, more sustainable operations.

In conclusion, the significance of centre rollers extends far beyond their mechanical functionality; they embody the intersection of engineering excellence and industrial efficiency. By understanding and optimizing this technology, industries can ensure better productivity, reduced costs, and a sustainable future.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025