Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Dynamics of Central Roller Mechanisms in Engineering Applications

The Centre Roller A Crucial Piece of Equipment in Modern Machinery

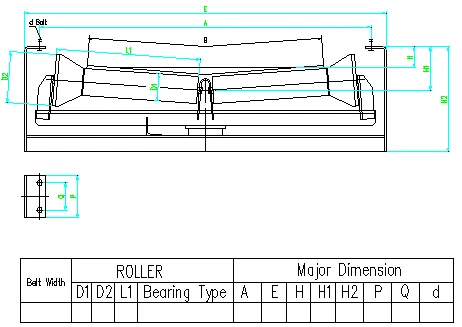

In the dynamic world of manufacturing and logistics, efficiency and precision play pivotal roles. Among the critical components that facilitate these attributes is the centre roller—a seemingly simple, yet indispensable element in a variety of machines and systems. The centre roller serves numerous functions and is vital in applications ranging from conveyor systems to industrial processes.

At its core, the centre roller is designed to provide support and movement to goods and materials as they traverse various stages of production or transport. Its configuration often consists of a cylindrical shape, allowing for smooth rolling motion, which minimizes friction and wear. The innovative design makes it ideal for applications that require a continuous flow of items, ensuring that operations run seamlessly without interruption.

One of the primary uses of centre rollers is in conveyor systems. In these setups, the rollers facilitate the movement of goods along a predetermined path. For instance, in a warehouse setting, items are often transported from one station to another using conveyor belts. Here, centre rollers play a crucial role in keeping the belt aligned and functional, preventing misalignment that could halt production or cause damage to merchandise.

centre roller

Moreover, centre rollers are commonly found in manufacturing lines, particularly in industries like automotive assembly, food processing, and packaging. In these environments, the reliability of each component is vital, as any malfunction could lead to a cascading effect, potentially resulting in costly downtimes. Centre rollers, therefore, must be constructed from durable materials that can withstand heavy loads and continuous use. This durability not only ensures operational efficiency but also extends the equipment's lifespan, providing a good return on investment for businesses.

The adaptability of centre rollers contributes significantly to their popularity. They can be engineered in various sizes and configurations to accommodate different weights and types of products. This versatility extends their use into more complex machinery, such as textile and printing machines, where precise handling of materials is essential for achieving high-quality results.

Additionally, the integration of technology into the design of centre rollers has enhanced their functionality. Modern versions may come equipped with sensors that monitor performance, detect wear, and provide real-time data analytics. Such intelligent rollers help prevent unforeseen breakdowns, allow for predictive maintenance, and improve overall system performance. As industries continue to embrace automation and smart technologies, the role of centre rollers will likely evolve even further, integrating more sophisticated features that enhance their efficiency.

In conclusion, while the centre roller may appear to be a minor component within the vast landscape of industrial machinery, its significance cannot be overstated. From ensuring the smooth operation of conveyor systems to enhancing the precision of manufacturing processes, centre rollers are essential for maintaining productivity and efficiency in various sectors. As technology advances, we can expect further innovations in the design and functionality of these rollers, reinforcing their status as a cornerstone of modern manufacturing and logistics. Businesses that prioritize the integration of quality centre rollers into their systems will undoubtedly position themselves for success in an increasingly competitive marketplace, benefiting from improved efficiency, longevity, and overall operational excellence.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025