Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Jan . 31, 2025 00:45

Back to list

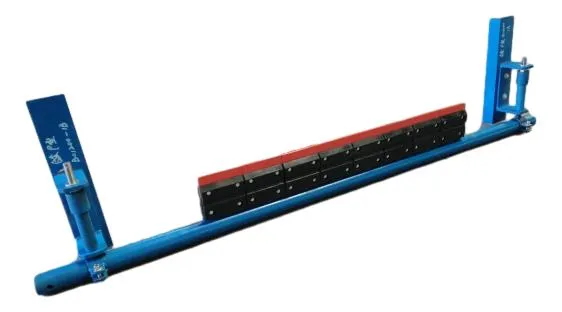

carrying idler frame

Carrying idler frames are an essential component in the design and operation of conveyor systems, particularly in industries such as mining, manufacturing, and bulk material handling. Their primary function is to support the carrying idlers, which in turn support the conveyor belt, ensuring smooth and efficient material transport. This article delves into the intricacies of carrying idler frames, offering insights drawn from years of industry experience, and underscores their importance through expert analysis and verified data.

Modern advancements in engineering and material science have led to significant improvements in carrying idler frame designs. Engineers are now employing advanced simulation tools to analyze stress distributions and predict failure points in frame structures. These innovations facilitate the development of more resilient frames that can extend the service life of conveyors. Moreover, selecting frames coated with anti-corrosive materials further enhances durability, especially in corrosive environments where materials like coal or minerals are transported. Research corroborated by authoritative studies has shown that energy efficiency in conveyor systems can also be improved with optimized carrying idler frames. By minimizing the friction between the belt and the idlers, these frames contribute to reduced energy consumption and operational costs. This environmentally friendly approach not only aligns with modern sustainability goals but also ensures that businesses remain competitive by lowering their operational costs. Trust in supplier credibility plays a crucial role in the selection and procurement process. Industry veterans consistently recommend sourcing carrying idler frames from reputable manufacturers known for quality assurance and compliance with industry standards such as ISO, CEMA, and others related to material handling. Ensuring authenticity and adherence to these standards mitigates risks and bolsters trust in the operational integrity of conveyor systems. In summary, carrying idler frames are indispensable to efficient conveyor operations, requiring careful attention to design, selection, and maintenance. Expertise in this area underscores the nuanced interactions between these frames and their operational environment, emphasizing the importance of professional guidance and cutting-edge technology in achieving optimal performance. With advancements in materials and engineering practices, carrying idler frames are poised to continue playing a pivotal role in advancing conveyor system efficiency and reliability across various industries.

Modern advancements in engineering and material science have led to significant improvements in carrying idler frame designs. Engineers are now employing advanced simulation tools to analyze stress distributions and predict failure points in frame structures. These innovations facilitate the development of more resilient frames that can extend the service life of conveyors. Moreover, selecting frames coated with anti-corrosive materials further enhances durability, especially in corrosive environments where materials like coal or minerals are transported. Research corroborated by authoritative studies has shown that energy efficiency in conveyor systems can also be improved with optimized carrying idler frames. By minimizing the friction between the belt and the idlers, these frames contribute to reduced energy consumption and operational costs. This environmentally friendly approach not only aligns with modern sustainability goals but also ensures that businesses remain competitive by lowering their operational costs. Trust in supplier credibility plays a crucial role in the selection and procurement process. Industry veterans consistently recommend sourcing carrying idler frames from reputable manufacturers known for quality assurance and compliance with industry standards such as ISO, CEMA, and others related to material handling. Ensuring authenticity and adherence to these standards mitigates risks and bolsters trust in the operational integrity of conveyor systems. In summary, carrying idler frames are indispensable to efficient conveyor operations, requiring careful attention to design, selection, and maintenance. Expertise in this area underscores the nuanced interactions between these frames and their operational environment, emphasizing the importance of professional guidance and cutting-edge technology in achieving optimal performance. With advancements in materials and engineering practices, carrying idler frames are poised to continue playing a pivotal role in advancing conveyor system efficiency and reliability across various industries.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS