Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu carrying idler frame

Understanding the Importance of the Carrying Idler Frame in Conveyor Systems

The carrying idler frame is a crucial component in the realm of conveyor systems, playing a pivotal role in the smooth operation and efficiency of material handling. Conveyors are widely used in various industries, including mining, manufacturing, and logistics, to transport bulk materials or products from one location to another. Among the various elements that constitute a conveyor system, the carrying idler frame stands out due to its multifaceted purpose in supporting, guiding, and stabilizing the conveyor belt.

What is a Carrying Idler Frame?

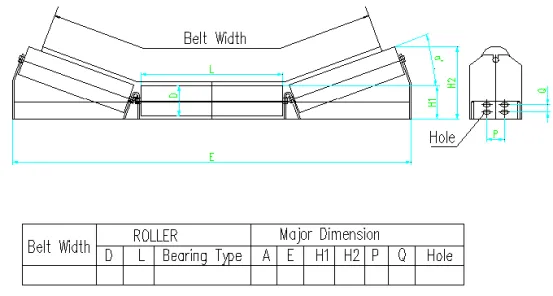

A carrying idler frame consists of a structured array of rollers mounted on a frame that supports the weight of the conveyed material on the belt. The components of the idler frame typically include a series of rollers that are strategically placed at intervals along the conveyor belt. These rollers are responsible for reducing friction as the belt moves, allowing for a smoother and more efficient operation. The stability offered by the carrying idler frame is crucial for ensuring that the conveyor system handles heavy loads without sagging or misalignment.

Functionality and Design

The design of the carrying idler frame is integral to its functionality. It must be robust enough to withstand the stress imposed by heavy loads while maintaining the proper alignment and tension of the conveyor belt. Moreover, the frame must allow for effective drainage of any materials that may accumulate on the belt, mitigating the risk of clogging, which could lead to operational delays.

Typically constructed from materials such as steel or reinforced plastic, carrying idler frames are designed to endure harsh operating conditions commonly found in industrial environments. Variations in the design, such as troughing idlers, flat idlers, and impact idlers, cater to different types of materials and operational requirements. For instance, troughing idlers are designed to hold the belt in a U-shaped configuration, thereby increasing the capacity to transport bulk materials without spillage.

Significance in Operational Efficiency

carrying idler frame

The significance of the carrying idler frame extends beyond its structural role; it also enhances the overall efficiency of conveyor systems. A well-designed idler frame minimizes belt wear and tear by ensuring the belt maintains correct alignment and tension. This factor is crucial, as improper belt alignment can lead to uneven wear, reducing the lifespan of the conveyor belt and increasing maintenance costs.

Furthermore, by reducing friction, the carrying idler frame aids in decreasing energy consumption associated with moving the conveyor belt. In industries where operational costs are paramount, such efficiencies can translate into substantial savings over time. Thus, investing in high-quality carrying idler frames can yield long-term benefits, making it a worthwhile consideration for any operations reliant on conveyor systems.

Maintenance and Best Practices

To maximize the performance of carrying idler frames, regular maintenance is essential. This includes inspecting the bearings of the idlers for wear, ensuring that rollers are clean and free from obstructions, and verifying that the frame is secure and properly aligned. Neglecting maintenance can lead to costly downtimes and repairs, as well as safety hazards due to the malfunctioning of the system.

In addition to maintenance, choosing the right type of carrying idler frame for the specific application cannot be overstated. Operators should consider factors such as the type of materials being transported, environmental conditions, and the overall design of the conveyor system.

Conclusion

The carrying idler frame is a fundamental element of conveyor systems that merits attention from system designers and operators alike. Its role in supporting and stabilizing the conveyor belt, coupled with its impact on operational efficiency, positions it as an indispensable component in material handling processes. By ensuring proper design, maintenance, and selection, industries can enhance conveyor performance, reduce costs, and improve overall productivity. As industries continue to evolve, the importance of robust conveyor systems and their components like the carrying idler frame will undoubtedly remain paramount in achieving operational excellence.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025