Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

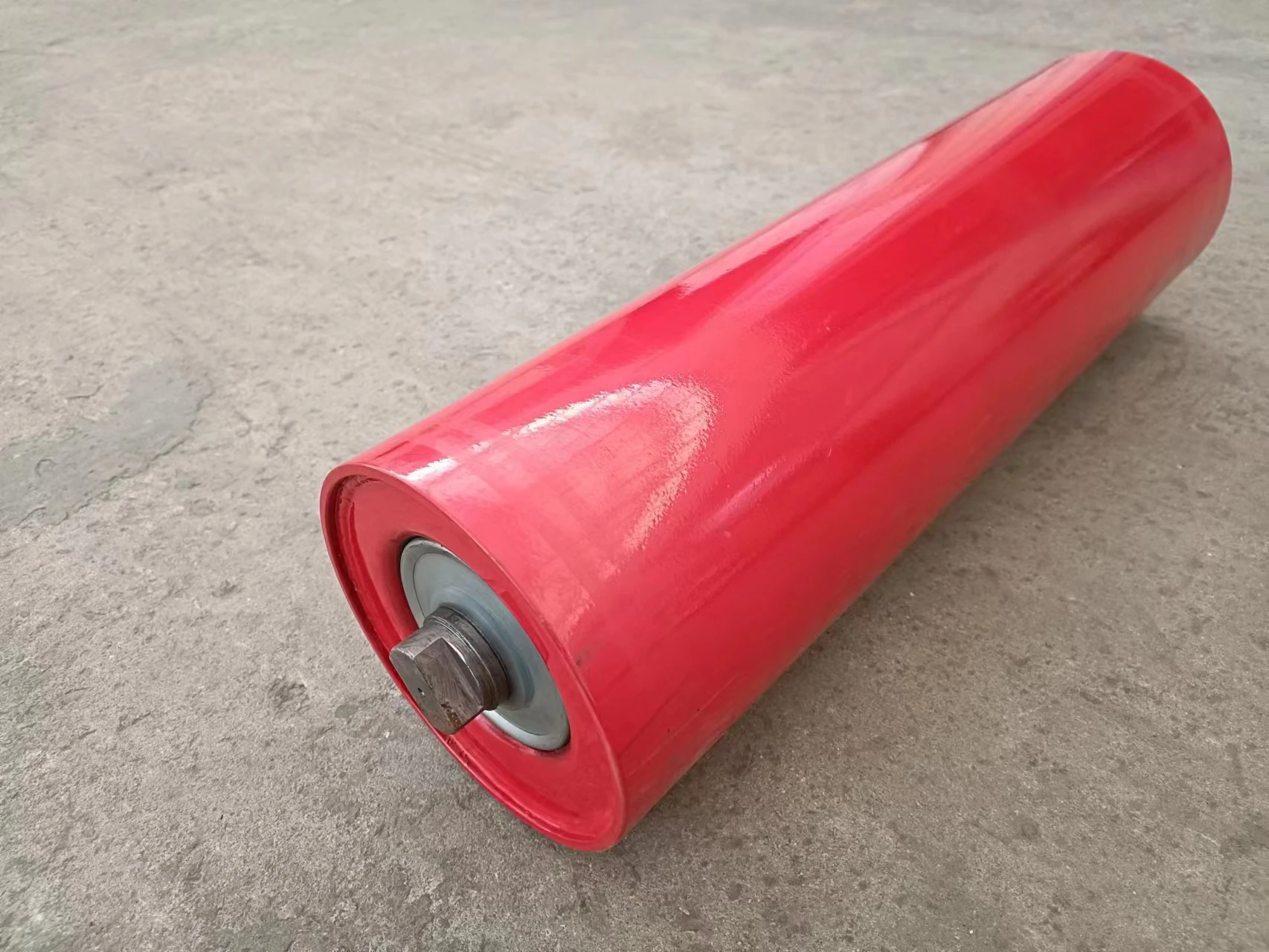

Zulu carry idler

The Concept of Carry Idler A Deep Dive

In the realm of engineering and mechanics, particularly in machinery design, the notion of carry idler emerges as a critical topic that warrants exploration. The term idlers generally refers to components or devices that support moving parts without being directly driven by them. Carry idlers specifically serve a dual function they support the load being transported and facilitate the movement of that load through a system, such as a conveyor belt. This article aims to elucidate the importance of carry idlers, their applications, and the factors that influence their design and efficiency.

The Role of Carry Idlers

Carry idlers are fundamental in various industrial applications, primarily due to their role in material handling systems. These components are strategically positioned along the length of conveyor belts to maintain the correct belt tension and alignment while carrying bulk materials. By reducing friction and offering support, carry idlers help in minimizing the power required to move materials, ultimately enhancing the efficiency of the entire system.

Moreover, carry idlers play a crucial role in prolonging the lifespan of conveyor belts

. By providing consistent support, they prevent excessive wear and tear on the belts, which can lead to costly downtimes and repairs. The design and material selection of these idlers directly affect not only the functionality of the conveyor system but also its operational costs over time.Types of Carry Idlers

Carry idlers come in various types, each designed for specific applications and environments. Some of the most common types include

1. Standard Carry Idlers These are the most widely used idlers, typically featuring three rollers and designed to support lightweight to medium loads. They are perfect for general distribution in various industries.

2. Heavy-Duty Carry Idlers As the name implies, these idlers are built to handle heavier loads and are commonly found in mining and quarrying operations where the demand for durability is high.

carry idler

3. Garland Idlers Utilizing a unique design where the idler rolls are arranged in a cascading manner, garland idlers are ideal for loading applications where material flows might present challenges.

4. Anti-Runaway Idlers These specialized idlers are designed to prevent materials from spilling off the conveyor belt during movement, ensuring a smoother operation in sensitive environments.

Factors Influencing the Design of Carry Idlers

Several critical factors influence the design and efficiency of carry idlers. One of the primary considerations is the load capacity. Engineers must ensure that the idlers can handle the maximum expected load without compromising performance. Additionally, environmental factors, such as exposure to moisture, temperature fluctuations, and chemical exposure, play a vital role in the material selection for idlers.

Friction is another crucial consideration. The design must aim to minimize friction between the idler and the conveyor belt. This not only aids in reducing the energy consumption of the system but also contributes to smoother material handling.

Lastly, maintenance requirements are an important factor. Carry idlers should be easy to inspect and maintain to ensure long-term reliability and performance. Regular maintenance can preemptively address issues that might lead to equipment failure.

Conclusion

In summary, carry idlers are indispensable components of material handling systems, providing essential support and functionality in various industrial applications. Understanding their design, types, and the factors that influence their efficiency is crucial for engineers and technicians seeking to optimize conveyor systems. By investing in high-quality carry idlers and focusing on proper design considerations, companies can enhance productivity and reduce operational costs, ultimately leading to more efficient and reliable machinery setups.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025