Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Exploring the Impact of Carrier Idler on Transportation Efficiency and Operations

Understanding Carrier Idler Key Insights and Implications

In the realm of logistics and shipping, the term carrier idler refers to periods during which a carrier, such as a shipping company or a freight service provider, is not actively engaged in transportation tasks. This can occur for various reasons, including delays, equipment maintenance, or waiting for cargo. Understanding the intricacies of carrier idler periods is crucial for optimizing supply chains, managing operational costs, and ensuring efficient service delivery.

The Nature of Carrier Idler

Carrier idler can be viewed through several lenses. At a basic level, it represents downtime, which can be detrimental to operational efficiency and profitability. For shipping companies, these idle periods mean that assets—be it ships, trucks, or planes—are not generating revenue. This idling can be simply defined as the time a carrier spends not moving cargo, which can arise from various causes such as

1. Scheduled Maintenance Carriers need regular maintenance to ensure safety and efficiency. Scheduling maintenance can lead to planned idler periods; however, unplanned breakdowns can cause unexpected delays.

2. Port Congestion High traffic at ports can cause ships to wait for berthing space. Port congestion can disrupt schedules and contribute significantly to idler time.

3. Bad Weather Adverse weather conditions can halt operations temporarily, causing vessels or trucks to remain idle until conditions improve.

4. Regulatory Delays Customs checks, inspections, or bureaucratic hurdles can contribute to longer wait times, resulting in idle carriers.

5. Waiting for Cargo Sometimes carriers arrive earlier than the cargo is ready to load. This scenario leads to waiting times that can be more or less predictable depending on coordination between shipping lines and cargo owners.

The Costs of Carrier Idler

The costs associated with carrier idler can be substantial. For shipping companies, idle assets mean lost revenue opportunities. Moreover, when vessels, trucks, or planes are not generating income, daily operating costs—including fuel, crew salaries, and maintenance—still incur. These costs can erode profit margins if not carefully managed.

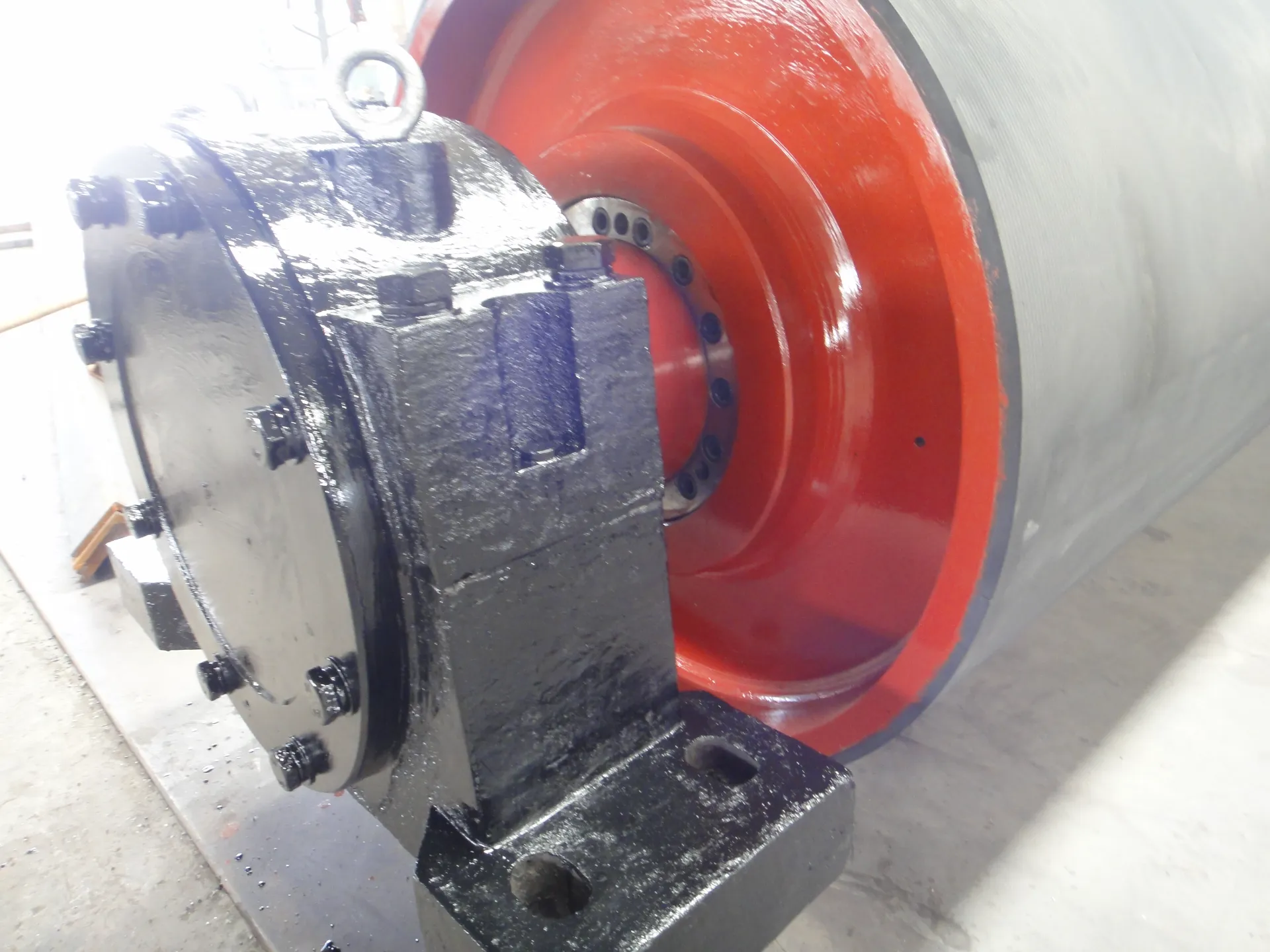

carrier idler

In addition, there are broader implications. Carrier idler can ripple through the entire supply chain. When carriers are held up, it affects delivery timelines, which can lead to dissatisfied customers and potentially lost business for shippers and manufacturers. Moreover, increased idler time can lead to higher congestion in cargo hubs, compounding the problem and leading to longer wait times for other carriers as well.

Strategies to Mitigate Carrier Idler

To minimize the impact of carrier idler on operations, companies can adopt various strategies

1. Real-Time Tracking and Communication Implementing advanced tracking technologies and fostering clear communication channels among stakeholders can significantly reduce downtime by ensuring timely updates about cargo readiness and transportation schedules.

2. Optimized Scheduling Using data analytics to forecast demand and streamline scheduling can allow carriers to synchronize their operations more closely with cargo readiness, thus reducing unnecessary idling.

3. Enhanced Maintenance Planning Proactive maintenance schedules can help avoid unexpected breakdowns, thereby reducing unplanned idler time.

4. Utilization of Technology Software solutions can help carriers manage routes efficiently, avoid congested areas, and make informed decisions about when and where to move assets.

5. Flexible Contracts Building flexibility into contracts with clients can accommodate unexpected delays and assist in managing expectations and reducing the fallout from idle periods.

Conclusion

In the fast-paced world of logistics and shipping, effectively managing carrier idler is vital for maximizing efficiency and profitability. By understanding the causes and implications of carrier idler, shipping companies can adopt strategies to mitigate its effects, ultimately leading to a more robust and responsive supply chain. As technology continues to evolve, leveraging data and advanced management techniques will be essential in navigating the complexities of modern logistics and ensuring carriers stay productive and profitable.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025