Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu carbon steel roller

Carbon Steel Rollers The Backbone of Industrial Operations

Carbon steel rollers play an essential role in various industrial applications, serving as the backbone in processes ranging from manufacturing to construction. Their robust properties, durability, and versatility make them indispensable in modern engineering and production. This article explores the significance of carbon steel rollers, their advantages, and their diverse applications.

Carbon steel, an alloy primarily composed of iron and carbon, is known for its strength and hardness. When shaped into rollers, it retains these properties, making it ideal for heavy-duty applications. The varying carbon content can be adjusted to achieve specific mechanical characteristics, allowing manufacturers to tailor the roller's performance to meet the demands of different industries.

One of the primary advantages of carbon steel rollers is their exceptional load-bearing capability

. They can withstand significant amounts of weight, making them suitable for heavy machinery, conveyor systems, and various mechanical assemblies. Their high tensile strength provides reliability under intense conditions, reducing the risk of deformation or failure. This durability is particularly important in industries such as mining, where equipment is exposed to harsh environments and heavy loads.carbon steel roller

In addition to strength, carbon steel rollers exhibit excellent wear resistance. When used in conveying materials or in machinery, these rollers can endure friction and impact without compromising their integrity. This wear resistance prolongs the lifespan of the rollers, resulting in lower maintenance costs and increased efficiency for businesses. Moreover, less frequent replacements lead to reduced downtime, which is crucial for maintaining productivity in fast-paced industrial operations.

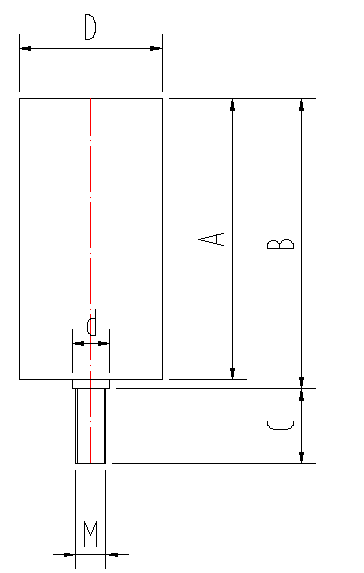

Another notable feature of carbon steel rollers is their versatility. They can be custom-engineered to fit various specifications, such as diameter, length, and surface finishing. This adaptability allows manufacturers to craft solutions tailored to specific applications, whether in automated assembly lines, packaging systems, or material handling equipment. The ability to tailor the roller’s design ensures that it performs optimally, enhancing operational efficiency.

Carbon steel rollers also provide a cost-effective solution compared to other materials such as stainless steel or aluminum. While they offer slightly less resistance to corrosion, with proper surface treatments and protective coatings, the longevity and strength of carbon steel often justify its use as the preferred choice for many manufacturers. This economic advantage is particularly appealing for small to medium-sized enterprises looking to optimize their operations without compromising quality.

In conclusion, carbon steel rollers are a vital component in various industrial sectors. Their strength, wear resistance, and versatility contribute significantly to the efficiency and reliability of machinery and manufacturing processes. As industries continue to evolve, the demand for durable and cost-effective solutions like carbon steel rollers will undoubtedly persist, solidifying their status as essential elements in modern industrial applications. Whether in construction, fabrication, or logistics, the role of carbon steel rollers is crucial in driving productivity and innovation in today’s competitive market.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025