Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu Feb . 11, 2025 09:27

Back to list

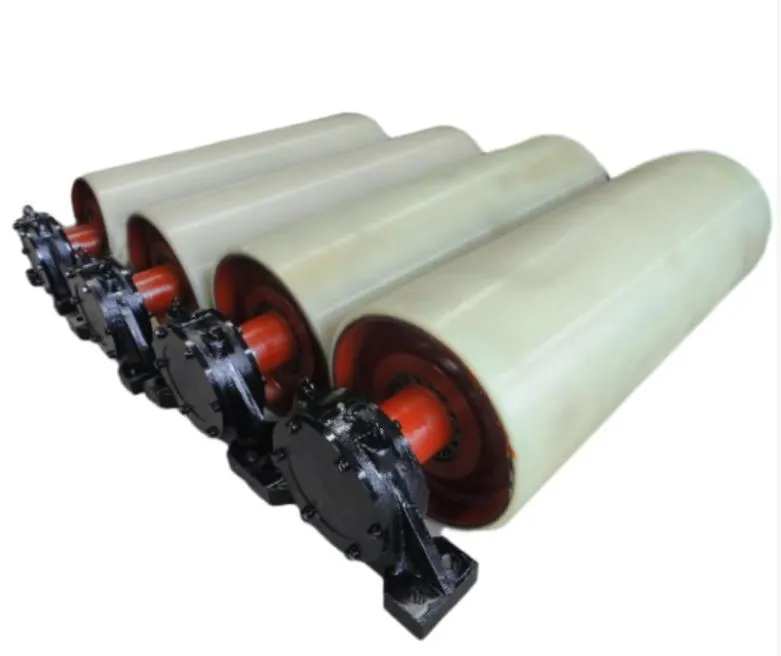

bend pulley and snub pulley

Bend pulleys and snub pulleys play crucial roles in the efficient functioning of conveyor belt systems, fundamental in industries ranging from mining to food processing. Understanding and leveraging the nuanced functionality of these components can significantly enhance operational efficiency and longevity.

Practically, those engaged in rigorous industries can augment the longevity and efficiency of their conveyor systems by investing in high-quality pulleys. Trust in manufacturers who offer warranties and provide clear guidelines on installation and maintenance can often lead to better operational results. Additionally, utilizing diagnostic technologies such as thermal imaging and vibration analysis can proactively detect issues with pulleys before they manifest as costly disruptions. Industry best practices also emphasize the importance of aligning pulley investments with broader maintenance strategies. This holistic approach includes scheduled inspections, belt tension audits, and the replacement of worn components. Such efforts are geared towards not only prolonging the life of the pulleys themselves but also enhancing the overall reliability of the conveyor system. In summary, the sophisticated engineering of bend and snub pulleys underpin their vital roles in conveyor systems. Mastery in the deployment and maintenance of these components can drive substantial improvements in operational efficiency, reducing downtime and fostering cost-effectiveness. With the confluence of experience, expertise, authoritativeness, and trustworthiness guiding pulley management strategies, industries can harness the full potential of these essential components.

Practically, those engaged in rigorous industries can augment the longevity and efficiency of their conveyor systems by investing in high-quality pulleys. Trust in manufacturers who offer warranties and provide clear guidelines on installation and maintenance can often lead to better operational results. Additionally, utilizing diagnostic technologies such as thermal imaging and vibration analysis can proactively detect issues with pulleys before they manifest as costly disruptions. Industry best practices also emphasize the importance of aligning pulley investments with broader maintenance strategies. This holistic approach includes scheduled inspections, belt tension audits, and the replacement of worn components. Such efforts are geared towards not only prolonging the life of the pulleys themselves but also enhancing the overall reliability of the conveyor system. In summary, the sophisticated engineering of bend and snub pulleys underpin their vital roles in conveyor systems. Mastery in the deployment and maintenance of these components can drive substantial improvements in operational efficiency, reducing downtime and fostering cost-effectiveness. With the confluence of experience, expertise, authoritativeness, and trustworthiness guiding pulley management strategies, industries can harness the full potential of these essential components.

Latest news

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025

OUR PRODUCTS