Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

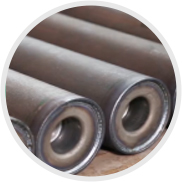

Zulu bend pulley and snub pulley

Understanding Bend Pulley and Snub Pulley in Mechanical Systems

In the realm of mechanical engineering, the design and efficiency of belt-driven systems are paramount. Two crucial components that often come into play in these systems are the bend pulley and the snub pulley. Understanding their functions, applications, and significance can provide valuable insights into the operation of various machinery, from conveyors to manufacturing equipment.

What are Bend Pulleys?

Bend pulleys, also known as guide pulleys or bending pulleys, are essential in guiding the movement of belts within a mechanical system. Their primary function is to redirect the movement of the belt, which is crucial in ensuring that the belt remains aligned and operates smoothly. Bend pulleys are typically placed at points where the direction of the belt must change, such as in tensioning systems or complex routing setups.

One of the key characteristics of bend pulleys is their diameter. The size of the pulley affects the radius of the belt's bend, which in turn influences the stress and wear on both the belt and the pulley itself. A larger bend radius generally results in reduced wear, increasing the lifespan of both components. Additionally, a well-designed bend pulley can minimize the friction between the belt and pulley surface, enhancing overall efficiency.

Bend pulleys are often found in a variety of applications, including

- Conveyor Systems In these systems, bend pulleys help redirect the belt around corners or inclines. - Textile Machines Bend pulleys guide belts used in the process of weaving or knitting. - Automotive Applications In engines, bend pulleys play a crucial role in managing the serpentine belts that drive multiple components.

Exploring Snub Pulleys

bend pulley and snub pulley

In contrast to bend pulleys, snub pulleys serve a different purpose in the mechanics of a belt-driven system. Snub pulleys are primarily used to increase the tension in a belt, ensuring that it remains in constant contact with the driving pulley. This is particularly important in applications where slippage could lead to inefficiency or failure.

The placement of a snub pulley can have a significant impact on the performance of the system. By strategically positioning a snub pulley near the driven pulley, engineers can create additional contact points that improve friction and grip, leading to better performance. This additional tension is especially vital in systems where there are significant changes in load or where the belt may experience sudden forces that could lead to slippage.

Applications of snub pulleys include

- Belt Drives in Machinery Snub pulleys are often used to maintain proper tension in belt drives associated with motors and other machinery. - Industrial Equipment In manufacturing lines, snub pulleys help ensure that belts consistently engage with the necessary components to avoid downtime. - Agricultural Machinery Snub pulleys are often employed in tractors and harvesters to maintain the tension needed for efficient operation.

Conclusion

Both bend pulleys and snub pulleys are integral parts of many mechanical systems. While bend pulleys are essential for guiding and redirecting belt movement, ensuring minimal wear and efficient operation, snub pulleys play a critical role in maintaining tension and preventing slippage. Understanding the distinct functions and applications of these pulleys can lead to more efficient designs and operations in various mechanical systems.

In everyday usage, the importance of these components may be overlooked, yet they serve as the backbone of countless industries—from manufacturing to transportation. Continued advancements in engineering and materials science will no doubt lead to even more innovative uses for bend and snub pulleys, underscoring their significance in the dynamic world of mechanical systems. As we strive for enhanced efficiency and productivity, a greater appreciation for these components will not only benefit machine performance but also pave the way for future technological advancements.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025