Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu bend pulley and snub pulley

Understanding Bend and Snub Pulleys Key Components in Mechanical Systems

In mechanical engineering and various industries, pulleys play a vital role in the functioning of systems. Among the different types of pulleys, bend pulleys and snub pulleys are particularly significant due to their unique applications and importance in enhancing the efficiency of mechanical operations. This article delves into the characteristics, functions, and applications of bend pulleys and snub pulleys, highlighting their roles in conveyor systems, lifts, and other machinery.

Bend Pulleys

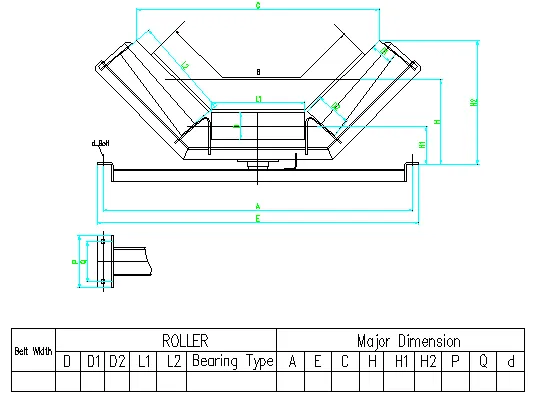

Bend pulleys are specifically designed to redirect the path of a belt, cable, or rope in a system. They are often used in applications where a change in direction is necessary. The primary function of a bend pulley is to maintain tension on the belt and to ensure that it adheres to the correct track. This is particularly crucial in scenarios where a belt must navigate around corners or obstacles.

The design of a bend pulley typically includes a grooved surface that matches the profile of the belt it interacts with. This groove ensures proper alignment and minimizes slippage during operation. Bend pulleys can be found in various industries, including mining, agriculture, and manufacturing, where they help transport materials over long distances or navigate around equipment and infrastructure.

Snub Pulleys

Snub pulleys, on the other hand, serve a different primary purpose. They are used to increase the tension in a belt by adding an additional contact point. This additional contact facilitates better grip and reduces the likelihood of slippage. Snub pulleys are crucial in systems where the power transmission needs to be enhanced, such as in conveyor belts and drive systems.

The placement of a snub pulley is strategic. Typically, it is positioned in line with the drive pulley and the tensioning mechanism. By creating more contact area, snub pulleys increase the friction between the belt and the pulley, leading to improved performance and efficiency. In many cases, snub pulleys also play a role in adjusting the tension in a belt system, ensuring that the drive operates smoothly without undue wear on the components.

bend pulley and snub pulley

The Differences and Interrelationship

While both bend and snub pulleys are integral to the efficiency of belt systems, their functions and applications differ markedly. Bend pulleys are primarily about redirecting the belt's trajectory, while snub pulleys focus on enhancing tension and grip. These distinct characteristics, however, do not mean that they operate in isolation; rather, they often work in tandem within a single mechanical setup to achieve optimal performance.

For instance, in a conveyor system, bend pulleys can redirect the material-carrying belt around corners, while snub pulleys help maintain the tension necessary to drive the belt forward efficiently. This synergy is essential for achieving the desired velocity, load capacity, and longevity of the belt system.

Applications in Various Industries

Both bend and snub pulleys are utilized across a multitude of industries. In manufacturing, they are crucial for the operation of conveyor belts that transport materials to different stages of production. In the mining industry, bend pulleys often redirect belts that carry ore and waste materials across uneven terrain, while snub pulleys ensure that the heavy loads are transported smoothly without slippage.

Moreover, in automotive applications, these pulleys are essential in timing belts and engine drive systems. Properly configured bend and snub pulleys can significantly influence the efficiency of the system, reducing wear and tear on components and improving overall machinery performance.

Conclusion

In summary, bend and snub pulleys are fundamental components that contribute significantly to the efficiency and effectiveness of mechanical systems. Understanding their roles, characteristics, and interrelationship is essential for engineers and professionals in industries reliant on material transport and power transmission. Proper design and maintenance of these pulleys ensure optimal performance and longevity of mechanical systems, ultimately leading to increased productivity and reduced operational costs. As technology advances and industries evolve, the roles of bend and snub pulleys will undoubtedly adapt, continuing to serve as cornerstones in the engineering landscape.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025