Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu belt scraper

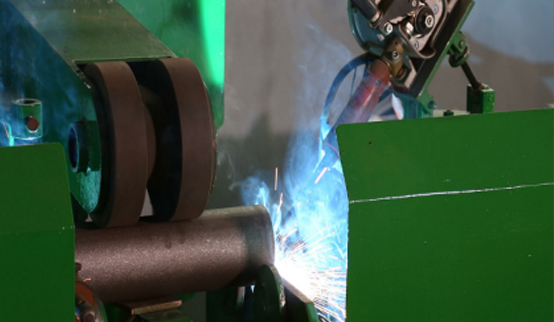

The Importance of Belt Scrapers in Conveyor Systems

Belt scrapers are essential components in the world of material handling and conveyor systems. They serve a pivotal role in ensuring operational efficiency, maintaining equipment longevity, and promoting safety in various industrial applications. As companies strive for optimal productivity, understanding the significance of belt scrapers becomes increasingly crucial.

At their core, belt scrapers are devices mounted on conveyor belts, primarily used to remove residue, debris, and other materials that cling to the surface of the belt during operation. These scrapers help to keep the belt clean, ensuring that it operates smoothly and efficiently. Without proper scraping, materials can build up on the belt, leading to a myriad of problems such as belt misalignment, increased wear and tear, and even operational failures.

One of the most notable advantages of using belt scrapers is the enhancement of product quality. In industries such as food processing, pharmaceuticals, and packaging, maintaining cleanliness is not just a matter of efficiency, but also compliance. Contaminated products can lead to unsafe conditions for consumers and significant financial liabilities for producers. By employing an effective belt scraper, companies can reduce the risk of contamination, leading to higher product quality and safer end products.

Additionally, clean conveyor belts contribute to reduced maintenance costs. When belts are properly scraped, the risk of damage from accumulated materials is significantly lessened. This can lead to a longer lifespan for the conveyor equipment, as well as reduced downtime caused by maintenance or repair work. In the long run, investing in high-quality belt scrapers often results in substantial cost savings and improved return on investment.

belt scraper

Safety is another paramount concern in industrial operations. Conveyors can be hazardous if not maintained properly, with dirty belts contributing to slipping hazards and potential accidents. By effectively removing materials from the belt’s surface, scrapers help improve traction and reduce the likelihood of accidents, thereby promoting a safer workplace. This aspect is particularly crucial in industries where employees work in close proximity to moving machinery.

When selecting belt scrapers, companies should consider several factors. The type of material being conveyed, the environment in which the conveyor operates, and the specific requirements of the application are all critical in determining the appropriate scraper design. There are various types of scrapers, including primary and secondary scrapers, each serving a unique function. Primary scrapers are generally positioned at the discharge point of the belt, while secondary scrapers are located further down the belt line to catch any remaining material.

Continual innovation in scraper technology has led to the introduction of various materials and designs aimed at improving efficiency and functionality. For instance, urethane scrapers are popular due to their durability and wear resistance, making them suitable for handling abrasive materials. Meanwhile, adjustable scrapers allow for precise tension adjustments to accommodate different belt conditions, ensuring effective cleaning regardless of wear or belt stretching.

In conclusion, belt scrapers are indispensable tools for optimizing conveyor system performance. By ensuring clean belt surfaces, they contribute significantly to product quality, reduce maintenance costs, and enhance workplace safety. As industries evolve and demand for efficiency increases, the role of belt scrapers will undoubtedly remain critical. Companies should prioritize the selection and maintenance of these vital components to achieve operational excellence and sustainability in their material handling processes. With the right scraper in place, the benefits extend far beyond cleanliness, impacting the overall success of the business.

-

Revolutionizing Conveyor Reliability with Advanced Rubber Lagging PulleysNewsJul.22,2025

-

Powering Precision and Durability with Expert Manufacturers of Conveyor ComponentsNewsJul.22,2025

-

Optimizing Conveyor Systems with Advanced Conveyor AccessoriesNewsJul.22,2025

-

Maximize Conveyor Efficiency with Quality Conveyor Idler PulleysNewsJul.22,2025

-

Future-Proof Your Conveyor System with High-Performance Polyurethane RollerNewsJul.22,2025

-

Driving Efficiency Forward with Quality Idlers and RollersNewsJul.22,2025